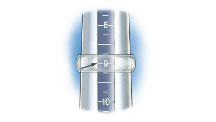

Finger hole is round.

Sizing Down Platinum Rings

Sizing Up Platinum Rings

Additional Topics

Finger hole is round.

Chamfering lets laser pulses completely penetrate the central portion of the joint. Platinum cobalt laser wire will be used to fill the joint.

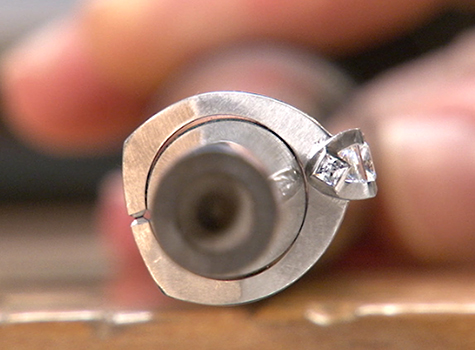

Attempting to round the ring prior to welding could cause damage to the channel-set princess-cut stones.

Sizing Down a Platinum Cobalt Ring with Diamonds using a Laser Welder

playThis is a modal window.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

The initial pulses from the laser bonded the shank metal at the core of the joint.

Use very slight and small pulls to round the ring. Stretching too much will cause the ring to tear, crack, become too large, and loosen the stones. This rounding technique should be the last step in the process and used only if necessary.