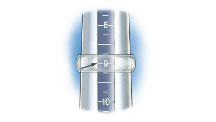

Sizing Down Platinum Rings

Sizing Up Platinum Rings

Additional Topics

Sizing Down Platinum Cobalt with no Diamonds in the Shank Using a Torch

playThis is a modal window.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.