All gemstones are tight, secure, and undamaged

Sizing Down Platinum Rings

Sizing Up Platinum Rings

Additional Topics

All gemstones are tight, secure, and undamaged

Alternatives to burnishing a platinum ring prior to finishing include filing, heavy polishing, and using abrasive wheels. Since these reduce structural integrity, burnishing is the preferred method.

Burnishing the scratches maintains the integrity of the metal weight and shape

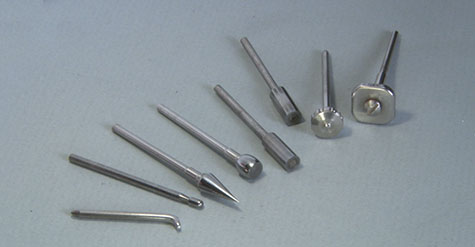

Burnishing platinum jewelry to remove gouges and scratches

playThis is a modal window.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

This is a modal window. This modal can be closed by pressing the Escape key or activating the close button.

This one features a highly polished stainless steel tip with a curved, smooth surface. For ease of use, it’s mounted in a wooden handle. This tool is useful for burnishing light scratches in platinum ring shanks.

This small L-shaped burnisher was fashioned from a used rotary tool. It is ideal for moving metal into depressions. It leaves an irregular finish on platinum that will need some abrasive finishing and light polishing.