Working with platinum is different than working with silver and white gold. Platinum is easily contaminated, so working with it requires a clean environment and, in some cases, dedicated tools.

Keeping dedicated tools for platinum work will shorten set-up time and make performance of repair services, alterations, and custom orders more efficient

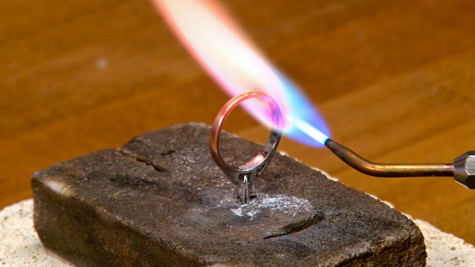

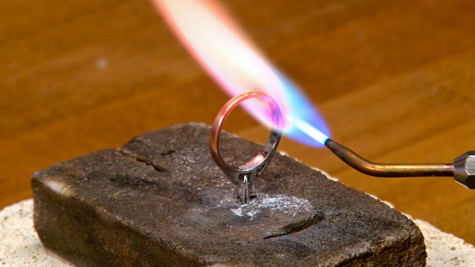

Gold filings that come in contact with platinum are a major contamination source. For example, when gold filings are on a platinum surface that is heated to platinum-soldering temperatures, the gold will leach into the platinum and leave visible traces that cannot be removed by polishing. Contamination from excess gold, silver, or other non-platinum metals can also lead to meltdown of the platinum piece during the soldering process.

A good practice is to have a dedicated container for storing platinum tools when they are not in use. Here the bench jeweler is using a metal cup to hold platinum-dedicated tweezers and files.

Use dedicated solder containers. It is bad practice to cut solder and place it on a soldering board. This practice picks up debris that will contaminate a platinum piece.

Note that the jeweler is using a flat bench pin that is only used for working with platinum

Save time by using dedicated and commonly used or favorite pliers for platinum working