HPHT and CVD Diamond Growth Processes: Making Lab-Grown Diamonds

July 25, 2016

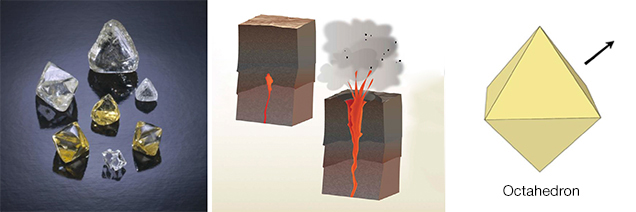

Gem-quality synthetic or laboratory-grown diamonds are more available in today’s jewelry marketplace than ever before, causing both interest and concern about lab-grown diamonds and whether gemologists or gemological labs can identify them.

GIA has studied lab-grown or manmade diamonds extensively over the past 30 years, and we know a great deal about the methods used to produce them and how they can be recognized. While synthetic diamonds are produced in factories, their chemical and physical properties correspond very closely to that of natural diamonds.

Some people might refer to lab-grown diamonds as imitations or simulants, but this is incorrect. Actual imitations like cubic zirconia or synthetic moissanite — which only look like diamond — have very different chemical and physical properties that allow trained gemologists to identify them easily. However, lab-grown diamonds are more challenging to detect.

In some cases, a trained gemologist can recognize these CVD/HPHT grown and treated diamonds by using standard gem-testing equipment. In other cases, identification requires testing the diamond using advanced scientific instruments. At GIA, we have a large database on the gemological properties of many different types of diamonds, which we use to develop additional methods of diamond identification.

An Introduction to Lab-Grown Diamonds

Scientists first grew diamonds in a laboratory in the mid-1950s. These diamonds were too small for jewelry, however. Production of larger, gem-quality crystals began in the mid-1990s and continues to today, with more and more companies producing synthetic diamonds. Synthetic diamonds are grown in several countries for both jewelry and industrial purposes — with industrial use being the primary function of the material (Large Colorless HPHT Synthetic Gem Diamonds from China, Gem News International, Gems & Gemology, Spring 2016, Vol. 52, No. 1).

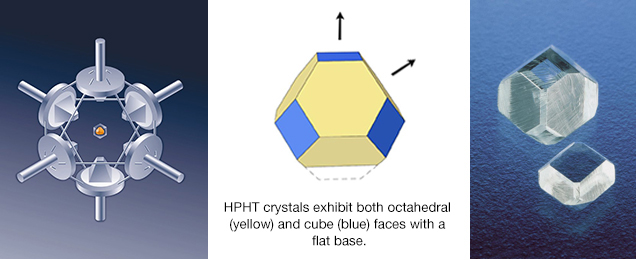

With the traditional diamond growth method, called high-pressure, high-temperature (HPHT), synthetic diamonds are produced from carbon material in apparatuses that mimic the high pressure, high temperature conditions of natural diamond formation in the earth.

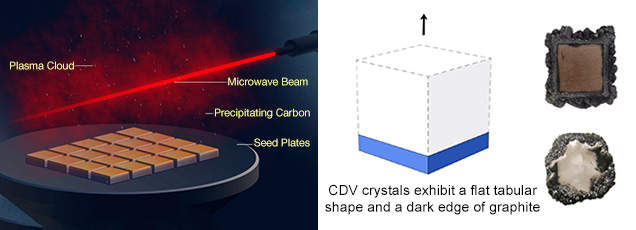

The newer method, chemical vapor deposition (CVD), involves filling a vacuum chamber with carbon-containing gas that crystallizes on a synthetic diamond seed. This method uses lower temperatures and pressures than HPHT. Both methods are currently popular methods of diamond growth. The CVD diamond growth method requires a lower upfront equipment cost than HPHT but may require subsequent treatment to improve the color of the diamonds grown.

What is a High-Pressure High-Temperature (HPHT) Diamond?

HPHT stands for high pressure, high temperature and is one of the primary methods used to grow diamonds in a lab. This diamond growth process subjects carbon to extreme temperatures and pressures and is meant to replicate the extreme heat and pressure conditions deep within the earth where natural diamonds form.

The HPHT Diamond Growth Process

- Diamond seed is placed in a specifically designed press.

- The growth chamber is heated to 1300-1600 °C with pressures above 870,000 pounds per square inch.

- The molten metal dissolves the high purity carbon source.

- Carbon atoms precipitate on a small diamond seed crystal, and a synthetic diamond begins to grow.

- The lab-grown crystal is then cut and polished by a diamond cutter.

In greater detail, HPHT diamond growth takes place in a small capsule inside an apparatus capable of generating very high pressures. Within the capsule, a carbon starting material, such as graphite, dissolves in a molten flux consisting of metals such as iron (Fe), nickel (Ni) or cobalt (Co), which lowers the temperature and pressure needed for diamond growth. The carbon material then migrates through the flux towards the cooler diamond seed and crystallizes on it to form a synthetic diamond crystal. Crystallization occurs over a period of several days to weeks to grow one or several crystals.

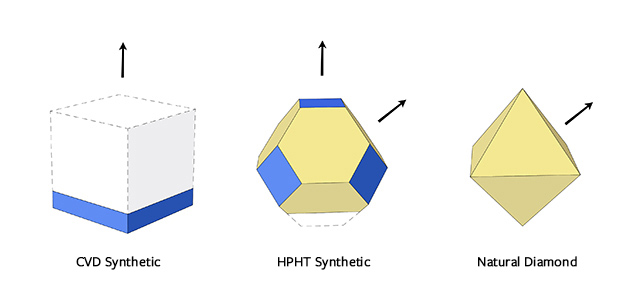

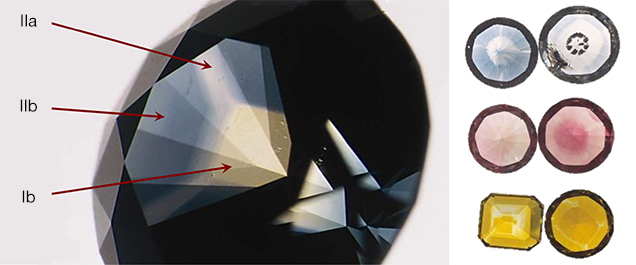

While natural diamond crystals tend to form as octahedrons, HPHT synthetic diamond crystals typically have cubic faces in addition to octahedral ones. Because the shapes of natural and HPHT synthetic diamond crystals are different, their internal growth patterns also differ dramatically. These growth patterns are among the most reliable ways to separate natural from synthetic diamond crystals.

The resulting faceted synthetic gems often exhibit distinctive color distribution, fluorescence zoning and graining patterns related to their cross-shaped growth-sector structure and also sometimes contain dark flux-metal inclusions. In some cases, the material exhibits phosphorescence, glowing after being exposed to ultraviolet light even when the light source has been turned off.

Growing colorless HPHT synthetics was once a challenge. Nitrogen, which turns diamonds yellow, had to be kept out of the growth environment. In addition, growing high-purity colorless diamonds required longer growth times and greater control over growth temperature and pressure conditions. Recent technological advancements, however, have allowed labs to produce colorless crystals that are faceted as diamonds 10 carats and above (15 Carat HPHT Synthetic Diamond, Lab Notes, Gems & Gemology, Summer 2018 Vol. 54, No. 2).

The addition of boron in the growth process results in blue crystals. Other colors — such as pink and red — can be produced by post-growth treatment processes that involve radiation and heating, but they are less common.

What is a Chemical Vapor Deposition (CVD) Diamond?

CVD stands for chemical vapor deposition and is another method used for making diamonds in a lab. Diamonds grow from a hydrocarbon gas mixture subjected to moderate pressures and temperatures in a vacuum chamber.

The CVD Diamond Growth Process

-

Diamond seed crystals are placed in a diamond growth chamber.

-

The chamber is filled with carbon-containing gas.

-

The chamber is heated to about 900-1200°C.

-

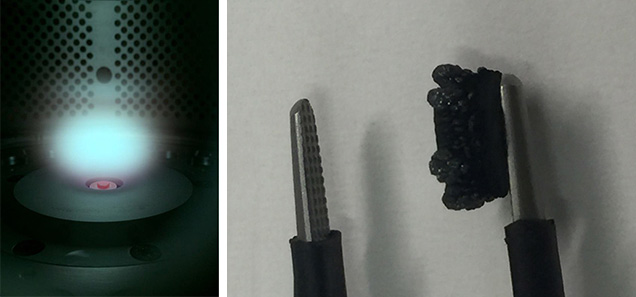

A microwave beam causes carbon to precipitate out of a plasma cloud and deposit onto a seed crystal.

-

Diamonds are removed every few days to have the top surface polished to remove any non-diamond carbon before being put back in to grow. Each batch of diamonds may require several stop/start cycles, and the entire growth process can take three or four weeks.

-

After the synthetic diamond crystals are removed, they are ready to be cut and polished into the final product.

In greater detail, CVD diamond growth takes place inside a vacuum chamber filled with a hydrogen and carbon-containing gas, such as methane. A source of energy — such as a microwave beam — breaks down the gas molecules, and the carbon atoms diffuse towards the colder, flat diamond seed plates. Crystallization occurs over a period of weeks, and several crystals grow at the same time. The exact number depends on the size of the chamber and the number of seed plates. The tabular crystals often develop a rough edge of black graphite that needs to be cut away. They also display a brown color that can be removed by heat treatment prior to faceting. Most CVD-grown colorless material on the market were probably once brown crystals that have been decolorized by HPHT annealing.

Like the HPHT diamond growth process, the CVD method continues to improve and allow manufacturers to offer larger sizes with improved color and clarity. (Observations on CVD-Grown Synthetic Diamonds: A Review, Gems & Gemology, Fall 2016, Vol. 52, No. 3)

How to Identify a HPHT or CVD Diamond

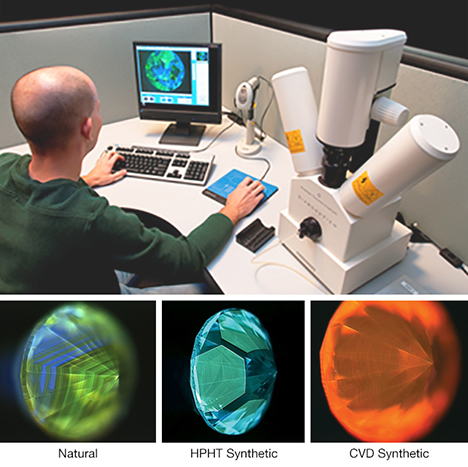

Even though synthetic diamonds have the same chemical make-up as natural ones, they have identifying markers caused by their growth conditions that GIA scientists use to tell them apart from natural diamonds. These markers even allow GIA scientists to identify which method had been used to grow the diamond.

| HPHT Synthetic | CVD Synthetic |

| Uneven color distribution | Even color distribution |

| Graining patterns | No graining patterns |

| Unusual fluorescence colors | Unusual fluorescence colors |

| Fluorescence color patterns | Fluorescence color patterns |

| Occasional phosphorescence | Occasional phosphorescence |

| Metallic flux inclusions | Occasional dark pinpoint inclusions |

| No strain patterns | Banded strain patterns |

| Possible inscription on girdle | Possible inscription on girdle |

The table above lists visual features characteristic of the majority of synthetic diamonds. Not every faceted synthetic diamond will exhibit all of these features, however. For example, a particular synthetic diamond may not display any fluorescence. Therefore, it is important to use as many diagnostic features as possible when identifying a diamond.

Color zoning is a particularly important diagnostic feature. HPHT colored synthetic diamonds often display geometric color zoning due to how elements, such as nitrogen, concentrate in the crystal as it forms. Natural diamonds will occasionally display color zoning, but their color zoning will not have geometric patterns like with HPHT synthetic diamonds. CVD-grown synthetic diamonds, on the other hand, usually have even coloration.

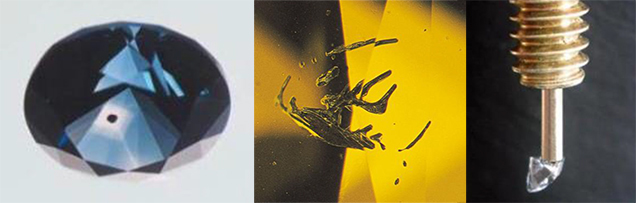

HPHT synthetic diamonds often contain metal flux inclusions that appear black and opaque in transmitted light but have a metallic luster in reflected light. That’s because the metals used as catalysts during the HPHT growth process can sometimes enter the diamond crystal. These flux metal alloys contain elements such as iron, nickel and cobalt. Synthetic diamonds with larger metallic inclusions can therefore sometimes be picked up with magnets.

CVD-grown synthetic diamonds do not have metallic inclusions. Rather, they often contain dark graphite inclusions or some other mineral inclusions that are a result of their unique growth process. Graphite inclusions appear different from metallic ones in that they do not have a metallic luster.

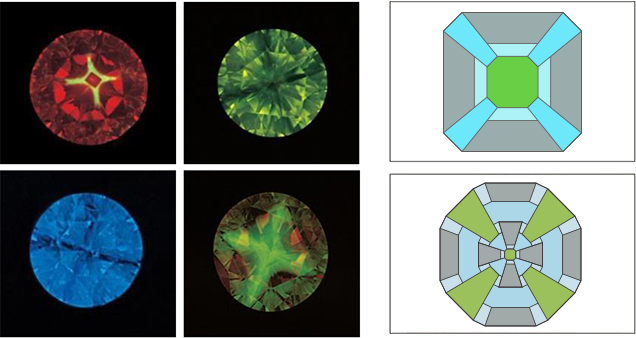

When examined between two polarizing filters angled at 90-degrees to one another, natural diamonds often exhibits a bright crosshatched or mosaic pattern of interference or “strain” colors. These interference colors arise from the diamond being subjected to incredible stress while deep in the earth or during its explosive eruption to the earth’s surface. CVD synthetic diamonds tend to display banded “strain” patterns, a marker that helps scientists tell them apart from HPHT synthetic diamonds. In contrast, HPHT grown synthetic diamonds grow in environments with nearly uniform pressure where they are not subjected to stress, so they display either no strain pattern or a weak banded strain pattern.

The fluorescence of synthetic diamonds is also often helpful for identification. Synthetic diamond fluorescence is often stronger under short-wave than under long-wave ultraviolet light, while the opposite is true of natural diamonds that fluoresce. Synthetic diamond fluorescence also often occurs in a distinctive pattern.

HPHT synthetic diamonds tend to show a cross-shaped fluorescence pattern on its crown or pavilion after being cut. CVD synthetic diamonds may show a striated (striped) pattern when viewed through their pavilion facets. Common fluorescence colors include green, yellow-green, yellow, orange and red.

Some synthetic diamonds might glow for a minute or more after the ultraviolet lamp is turned off. This is called phosphorescence and is typically only seen in synthetic diamonds.

At GIA, we use a fluorescence imaging instrument called a DiamondView™ to examine diamonds. This instrument reveals the growth patterns within diamond crystals.

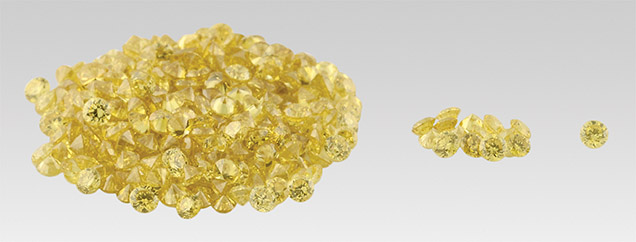

The real challenge, when it comes to diamond identification, is identifying tiny diamonds called melee. Melee is sold in the jewelry trade in parcels of hundreds to thousands of gemstones. Some parcels may include both natural and CVD/HPHT grown synthetic diamonds.

To meet this challenge, GIA has developed the GIA iD100®, an instrument for automated testing of very small diamonds that is available for purchase. We also offer a testing service for melee in our laboratory.

As part of our ongoing research on synthetic diamonds, GIA has a CVD growth facility where we produce our own CVD synthetic diamonds for study.

As synthetic diamond technology becomes increasingly sophisticated, GIA scientists are staying ahead with increasingly advanced testing techniques and research. To be certain of the identity of the diamond you are buying, make sure you buy a diamond with a GIA Diamond Grading Report or GIA Laboratory-Grown Diamond Report. Learn more about our melee testing service and diamond testing devices — the GIAiD100® and GIA DiamondCheck™.

Dr. Shigley is a distinguished research fellow at GIA in Carlsbad.