Emeralds Filled with Epoxy Resin: DiamondView Observations

Emeralds from all sources routinely contain surface-reaching fissures, and as a result are subjected to clarity enhancement processes (oiling or resin filling) to improve their appearance. The quantity and variety of emerald-filling substances undoubtedly affects the final market value (M.L. Johnson et al., “On the identification of various emerald filling substances,” Summer 1999 G&G, pp. 82–107). Recently, the Lai Tai-An Gem Lab received a stone—reported as an emerald by the client—for identification services, with a request to focus on the degree of clarity enhancement. DiamondView imaging allowed us to visually explain the degree of filling in a way the client was quickly able to understand.

-239698-636px.jpg)

The transparent emerald-cut stone weighed 16.15 ct and measured 16.80 × 14.07 × 9.48 mm. It exhibited a light to medium green saturation and contained white hazy inclusions that were visible to the eye (figure 1). Standard gemological testing revealed an RI of 1.570–1.575, an SG of approximately 2.66, and a weak yellowish green reaction under long-wave ultraviolet radiation. Magnification with a gemological microscope revealed fluid and three-phase inclusions typical of natural emeralds. When turning the specimen, “blue flashes” characteristic of resin-filled material were seen within many of the fissures (figure 2). These results confirmed that the stone was a natural, clarity-enhanced emerald. Infrared spectrometry was subsequently performed to analyze the filling in more detail. Epoxy resin peaks at 3061, 3040, 2965, 2930, and 2870 cm–1 (figure 3) confirmed the epoxy resin treatment of the stone, as indicated by the initial microscopy.

Although it may not be difficult for experienced gemologists to identify various emerald-filling substances using high-end equipment like Fourier-transform infrared (FTIR) or Raman spectroscopy, we wanted to check on the suitability of another tool to assist in identifying fillers and to help see the extent and degree of filling applied. We turned to the DiamondView and obtained some interesting images for this clarity-enhanced emerald.

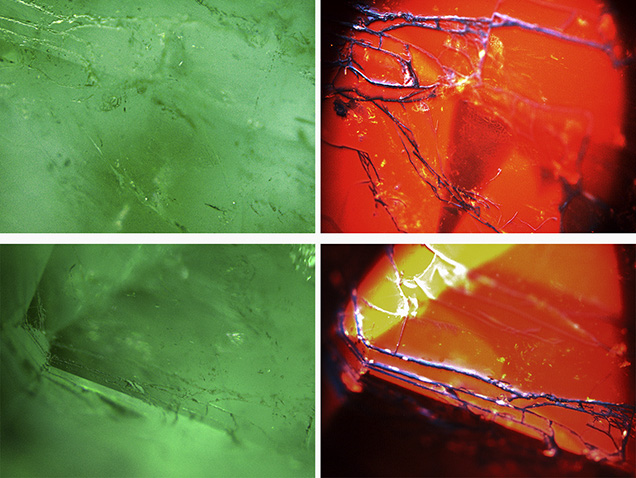

The stone’s surface was first observed in different directions under the DiamondView’s visible light source until obvious surface-reaching fissures appeared. Subsequent exposure to the unit’s ultra-short energy UV light clearly revealed the epoxy resin filler within the fissures as a series of blue lines extending over the entire surface against the beryl’s orange-fluorescing bodycolor. The more severe (quantity in relation to width and depth) the treated fissures were, the stronger the blue reaction (figure 4). The results of this simple test show how the DiamondView may be applied. Although the DiamondView cannot precisely identify the fillers, it does provide a means of detection that can be applied to a variety of gems. The option of ultra-short-wave radiation should be considered, as there may be concerns about the color and structural durability of host and fillers that have not been fully taken into account.