Jaipur, India: The Global Gem and Jewelry Power of the Pink City

ABSTRACT

In 2015, a field team from GIA visited the Indian city of Jaipur to capture the full scope of its gem and jewelry industry: colored stone cutting, wholesale trading, jewelry design, manufacturing, and retail. The authors documented the current state of the industry from a manufacturing as well as a business perspective. The results substantiated many of the team's prior assessments but also brought to light recent developments with far-reaching effects. The impact of vertical integration, consolidation, globalization, and jewelry television retail far exceeded expectations. Once known as a colored stone manufacturing center, Jaipur has rapidly climbed the value chain into jewelry manufacturing and retail by successfully incorporating experience and tradition with technology and innovation.

INTRODUCTION

In the colored gemstone mine-to-market journey, there are major trading centers where rough is imported for cutting and then exported as finished stones. Each has its own attributes, niches, and challenges. Some of the hubs for colored stone manufacturing include China, Thailand, Sri Lanka, and Jaipur, India. The authors have visited all of these manufacturing and trading centers and studied them in detail. In late April and early May 2015, the authors visited Jaipur to examine its role as a colored stone cutting center and its more recent emergence as a modern jewelry manufacturing powerhouse (figure 1). This visit had the advantage of years of experience documenting such industries in the field, and a formula for gathering the information needed to understand the individual characteristics of that location as well as how it fits in the global picture.

The team spent 10 days in Jaipur touring 20 companies and documenting their factory, trading, and retail operations. Many of these were family businesses, and we were able to interview multiple generations in preparing case studies. The authors conducted numerous interviews with their ownership, management, and production crews and collected over 80 hours of video and more than 10,000 photos. Our approach to understanding this dynamic colored stone center was to work with Indian trade organizations and industry leaders ahead of the trip to select as many companies as we could cover in the required time period and complete case studies on each one. The companies were chosen as representative of market sectors in the Jaipur industry, covering all the manufacturing and business aspects from traditional to modern. Like previous G&G reports on the gem and jewelry industries of China and Sri Lanka (Hsu et al., 2014; Lucas et al., 2014), the present article is largely based on these observations and interviews.

Members of the team who had visited Jaipur before came away with a different perspective of the industry there in some respects. Our impressions in Jaipur also completed a large part of the global colored stone picture. Gemfields’ auctions from its Kagem mine have had a profound effect on the city’s emerald industry. Indeed, we were surprised by the extent to which Zambia had overtaken Brazil as a supplier of emerald rough. Tanzania’s restrictions on rough tanzanite exports were another influence, but smaller sizes were still very much available and had found a new customer in jewelry television networks. In fact, one of our biggest takeaways was how much television retail has affected Jaipur and the global industry.

The success of these shopping channels in the United States, the United Kingdom, Canada, Japan, and other countries has led to an enormous demand for all types of calibrated colored stones. This has greatly diversified Jaipur’s colored stone cutting industry and expanded its scale of operations, with one factory cutting a million stones a month (N. Bardiya, pers. comm., 2015). As a result, some of these cutting companies have moved up the value chain into jewelry manufacturing. Many of these jewelry pieces are destined for television retailers and contain a variety of colored stones. In fact, one company was vertically integrated all the way to the end consumer, with its own television retail division reaching 100 million households, requiring approximately one million pieces of jewelry to be manufactured each month.

Another significant impression was Jaipur’s blend of the modern and the traditional. State-of-the-art mass production is complemented by a cottage industry of individual artisans using centuries-old methods. Companies that once served the maharajas coexist with manufacturers for online retail and television shopping networks. From traditional kundan meena to fusion jewelry combining eras and styles, Jaipur has become a jewelry manufacturing center as well as a gemstone cutting center.

INDIA

In any major Indian city, one can feel the energy of an ambitious, rising economic power. At every socioeconomic level there is a distinct entrepreneurial drive and competitive spirit. With a population of approximately 1.3 billion, India is the world’s largest democracy and the second most populous country, projected to overtake China in 2022 (Gladstone, 2015).

Although rich in history and tradition, India is a relatively new country. It gained independence from the United Kingdom in 1947 and became a republic in 1950. In the late 1980s, India began opening up to economic reform, trade, and foreign investment (“India country profile,” 2015). The population is 72% Indo-Aryan and 25% Dravidian, with Mongoloid and others representing just 3% (The World Factbook, 2016). The most widely spoken language is Hindi, but there are 14 other official languages and more than 1,000 languages spoken in the country. While English is a subsidiary official language, it is the most important for international commerce. Hindus make up almost 80% of the population, with Muslims accounting for 14.2% and Christians, Sikhs, and other groups making up the rest (The World Factbook, 2016).

India’s real GDP growth rate of 7.3% in 2015 placed it at 10th in the world. Forty-five percent of the country’s GDP is in the services sector, followed by industry at 29.7% and agriculture at 17%. The country’s estimated exports of US$272.4 billion in 2015 ranked 20th in the world. India has an estimated labor force of 501.8 million, ranking second in the world in 2015 (The World Factbook, 2016).

Visiting India, one is taken aback by the architecture and the overload of vibrant colors. From palaces to saris to fruits and vegetables, India is a stimulation of the senses on a grand scale. This culture of color spreads to personal adornment and India’s rich tradition of jewels and opulence, including colored gemstones and bold enamel colors. This is made abundantly clear in the French gem merchant Jean-Baptiste Tavernier’s Travels in India (1676). Descriptions of the Great Moguls’ seven thrones laden with diamonds, rubies, emeralds, and pearls offer a glimpse into the tradition of wealth and jewels in India.

JAIPUR

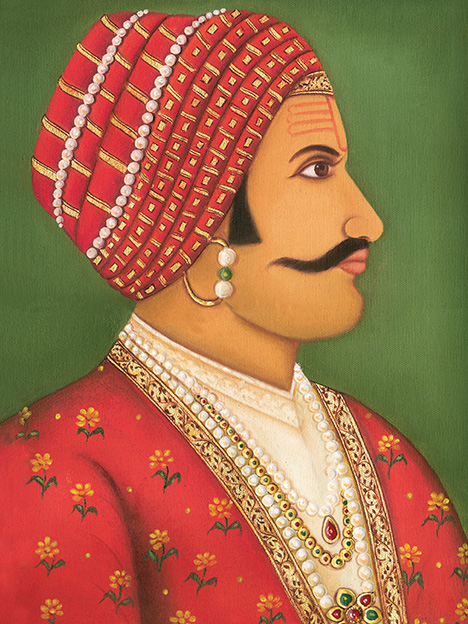

Jaipur is the capital of the state of Rajasthan in northwestern India (figure 2). Rajasthan has long been a strategic economic area because of its location on the trade route from China to Europe (Khullar, 1999). The city was founded in 1727 by Maharaja Sawai Jai Singh (known as Jai Singh II; see figure 3), the raja of Amer. Jaipur was India’s first modern planned city, based on traditional Hindu architecture. Access to water was a primary reason Jai Singh II moved his capital from Amer to this irrigated valley 11 km away (Khullar, 1999). The city was originally divided into nine blocks, two for state buildings and palaces and seven for the public. The old city’s buildings were painted pink, the traditional color of hospitality, to welcome Queen Victoria and the Prince of Wales in 1876, and Jaipur is still known as the Pink City. It is a popular tourist destination, with such attractions as Amer or Amber Fort, which was designated a UNESCO World Heritage site in 2013 (again, see figure 2); Albert Hall; Hawa Mahal; Jal Mahal; City Palace; and Jantar Mantar. Some tourists come specifically to get married in local fashion, wearing traditional clothing and jewelry.

THE GEM AND JEWELRY INDUSTRY IN JAIPUR

Almost at its conception, Jaipur became a city for skilled craftsmen who were drawn from around the region by Jai Singh II. These craftsmen included jewelers and stonecutters under the patronage of the maharajas. The jewelry they created embraced enameling and gemstones for magnificent colorful creations that were as carefully finished on the back as the front. The Johari Bazaar, one of the city’s oldest markets (Conway, 2010), was commissioned by Jai Singh II and marked the start of the gem and jewelry industry in Jaipur. The bazaar is still home to many small workshops and emporiums. Jaipur has built upon this rich tradition, with today’s entrepreneurs making the city a leading center for colored stone cutting and trading as well as modern jewelry manufacturing (figure 4).

The Gems and Jewellery Export and Promotions Council (GJEPC), formed in Jaipur by the Ministry of Commerce in 1966, works to promote the Indian gem and jewelry industry on behalf of some 6,000 exporters. During the organization’s first year, Indian exports of gemstones and jewelry were US$28 million. By 2014, that figure had risen to US$35 billion (http://www.gjepc.org/about_us.php). Much of this growth could be attributed to polished diamond and diamond jewelry exports, which far exceeded those of colored stones and colored stone jewelry (R. Jain, pers. comm., 2015).

Determining the total number of people working in the Jaipur gem and jewelry trade is difficult. The sector includes the city’s organized gemstone cutting and jewelry factories, as well as surrounding areas and a sizable cottage industry where families and households do contract manufacturing. The leaders we interviewed agreed that the figure is over 200,000, and some estimates put it closer to 300,000, with around 150,000 involved in the gemstone cutting sector.

In 2012, Gold Souk opened in Jaipur, with 95 showrooms and 150 offices featuring the city’s leading jewelers (“Gold Souk opens in Jaipur,” 2012). The souk caters to the flourishing tourism industry, offering a variety of jewelry styles to those visiting the city. The Jaipur Jewellery Show (JJS), held in December, attracts around 30,000 visitors annually to the Jaipur Exhibition and Convention Center (http://10times.com/jjs). The show, which started in 2003 with only 64 booths, features more than 700 vendors and includes finished jewelry and loose stones, and in 2015 it unveiled a new brand ambassador, Bollywood actress Amrita Rao (“Film actress Amrita Rao...,” 2015).

Jaipur’s gem and jewelry exports from April 2014 through March 2015 totaled more than US$574 million. Within that total, the largest category was colored gemstones at more than US$264 million. It is notable that finished gold jewelry was US$112.5 million and non-gold jewelry US$145 million (see table 1).

| TABLE 1. Jaipur gem and jewelry exports, 2010–2015 (in millions of U.S. dollars). | |||||

| April 2010 to March 2011 |

April 2011 to March 2012 |

April 2012 to March 2013 |

April 2013 to March 2014 |

April 2014 to March 2015 |

|

| Cut and polished diamonds |

23.0835 | 20.343 | 21.972 | 24.5715 | 18.606 |

| Gold jewelry | 74.529 | 79.932 | 88.359 | 118.221 | 112.506 |

| Colored gemstones | 186.6285 | 239.196 | 219.2505 | 276.111 | 264.834 |

| Pearls | 0.0135 | 0.012 | 0.072 | 0.735 | 0.0675 |

| Non-gold jewelry | 112.548 | 121.599 | 132.1185 | 146.244 | 145.158 |

| Costume fashion jewelry |

3.0855 | 6.7185 | 11.043 | 10.647 | 11.9205 |

| Raw synthetic | 0.0045 | 0.009 | 0.009 | 0.021 | 0.039 |

| Rough diamond | 0.051 | 0 | 0 | 0 | 0 |

| Rough colored gemstones |

3.045 | 11.6025 | 8.0775 | 12.015 | 20.037 |

| Synthetic stones | 0.3855 | 0.4335 | 0.918 | 1.4775 | 1.5405 |

| Total | 403.374 | 479.8455 | 481.899 | 590.043 | 574.7085 |

|

Source: GJEPC

Note: U.S. dollar amounts have been converted from Indian crore rupees (one crore equaling a quantity of 10 million) with November 2015 exchange rates. |

|||||

COLORED GEMSTONE INDUSTRY

In Jaipur there are at least 100 factories cutting colored gemstones. There is also a huge cottage industry of artisan cutters working on a contract basis (R. Jain, pers. comm., 2015). The industry is in many ways a complementary blend of traditional artisans in the cottage industry and large factories that employ thousands. Some of the large modern factories also contract their cutting work to the artisan cottage industry to expand their production capabilities when needed.

While Thailand and Sri Lanka control the global corundum cutting industry, Jaipur excels in many different colored gemstones, particularly emerald. The impact of television retailers and their jewelry manufacturers has been significant, driving demand for a variety of colored gemstones, including large volumes of calibrated sizes. If the supply of one type of gem diminishes, others that are available can be cut and marketed through television. With this constant demand, Jaipur’s rough buyers are purchasing a wide range of colored gemstones from sources all over the world.

Jaipur has been cutting Zambian and Brazilian emeralds for decades. Now much of the industry focus is on the Zambian supply, and the Gemfields auctions of that production have revolutionized the emerald cutting industry in Jaipur. The consistent supply of accurately graded parcels through regularly scheduled auctions has made it easier to plan for customer demand for finished stones. This benefit does come with the challenge of auction competitiveness and shrinking margins for the Jaipur cutters.

Since the 1980s Jaipur has been a major cutting center for tanzanite. Rough tanzanite export restrictions imposed by the Tanzanian government in December 2010 dramatically changed the face of tanzanite cutting in Jaipur. Some companies found it better to diversify into different colored gemstones, while others primarily focused on producing smaller calibrated tanzanites from the rough available to them. These smaller calibrated goods have a ready market from manufacturers creating jewelry for television shopping.

The Emerald Trade. The authors visited three emerald cutting factories in Jaipur. Two were manufacturing partners of a U.S.-based wholesaler but cut goods for different market sectors: one higher-quality and one more commercial-quality. Both companies source emerald rough and cut stones from Zambia, Brazil, and Colombia. The rough is cut at their own manufacturing facilities and through partners in Jaipur. The wholesale firm they work with, Real Gems, Inc. of New York City, is a family business with over 40 years in the emerald industry. Real Gems sells a wide variety of sizes and qualities, from precision-calibrated 1 mm rounds to untreated stones over 50 carats (figure 5). With offices in New York, Hong Kong, Dubai, Bangkok, and Europe, they strive to fill any emerald order from customers within 48 hours (S. Shah, pers. comm., 2015). The third company we visited cuts and sells its goods to foreign buyers in Jaipur. All three have slightly different rough procurement models, buying strategies, and customer bases. Together they represent significant strategies of the Jaipur emerald industry as a whole.

Multigem Creations. Multigem Creations started over 25 years ago and developed a business similar to that of other companies in the Jaipur emerald trade. The company first started buying emeralds from Bahia, Brazil, especially the Socotó mines, when large amounts of rough were available. Much of it consisted of cabochon, tumbled, and lower-clarity facet qualities. By 1990 and 1991, Multigem was producing 20,000 carats of finished goods per month. As production from Bahia declined, the company shifted its focus to Zambian emerald. By 1998, it was purchasing Zambian rough almost exclusively. Multigem continued to specialize in more-included commercial qualities with the Zambian rough, while preparing to move up to middle-market and higher-quality material. Over the next decade, the company abandoned the lower-quality commercial market.

With the shift to higher-quality material, the production of finished goods dropped from 20,000 carats to about 5,000 carats per month by 2005. Today that figure is 1,500 to 2,000 carats per month, but in higher qualities. This is because higher-quality material takes more time to evaluate and cut. Top-quality material also requires larger capital, and availability is limited. But Multigem’s total revenue has increased, and the price for better-quality Zambian rough and cut stones has doubled over the last six to seven years (N. Dugar, pers. comm., 2015). Still, the profit margins have been continuously squeezed as the cost of manufacturing and doing business has increased, even though far fewer employees are needed.

The company, which had a staff of 50 when it produced lower-quality material, has about a dozen employees today. The cutting staff consists of about seven master cutters, each with 20 to 48 years of experience. Company partner Naresh Dugar believes that becoming a skilled emerald cutter requires a minimum of 10 years’ experience, especially to work with better-quality material. He says that a cutter needs to see a large amount of rough to make the right decisions on planning the cut, sawing, preforming, and faceting (figure 6). With emerald in particular, color zoning, inclusions, and fissures must be balanced with shape, weight retention, and how the stone will respond to clarity enhancement.

The manufacturing team pools together its knowledge to discuss the cutting of important pieces of rough, so there can easily be at least 100 years of combined experience looking at a single stone. The company’s years of cutting lower- to medium-quality emeralds prepared it to move up to fine-quality rough. While it is not always easy to move finished emeralds in today’s market, Mr. Dugar noted that better-quality material is more appealing and marketable, almost always selling within a few months.

When Multigem started buying Zambian rough, the supply was consistent but the available lots had an undesirable mix of qualities and sizes. The quality within a rough lot might range in value from US$1 to US$1,000 per gram. This mixture made it difficult for manufacturers to focus on the quality needed for their business models.

Multigem no longer purchases rough primarily in the Zambian open market. About 60% of their rough comes from the Gemfields auction and 40% from local traders or Zambians who come to Jaipur to sell. The Gemfields auction system has made buying emerald rough much easier in the sense that the lots are very well organized by size and quality. Another important advantage is that the same quality grades are available from one auction to the next, allowing for better business planning. Thus, Multigem is able to provide consistent supply to customers over the years. At the same time, the auctions are very competitive. Anyone buying emerald rough at these auctions must have considerable experience and market knowledge, especially for higher-quality lots.

Multigem Creations is one of the companies that partners with Real Gems, the New York–based global emerald wholesaler, which has a strong customer base in the United States. Multigem also sells to local buyers in Jaipur. The company produces large faceted free-size stones, as well as calibrated faceted stones, cabochons, and tumbled stones. It focuses on better qualities for all types of cut material.

The authors observed an example of a common business decision in Jaipur: whether to cut a 250 ct piece of rough into a faceted stone or matching tumbled stones (figure 7). The matching tumbled stones would easily total more than 50 carats; at 20,000 rupees per carat, they might sell for a total of one million rupees. A 20 ct faceted stone might also be produced, but much of the depth of color would be lost due to color zoning and the emerald’s brightness would be hindered by inclusions. Faceted stones typically sell for more per carat, all things being equal. In this case, Mr. Dugar estimated that the faceted stone would also sell for 20,000 rupees per carat due to the loss of color and therefore bring only 400,000 rupees—600,000 rupees less than the matching tumbled stones. Understanding the nature of the crystal’s color zoning, the effect of inclusions on brightness, and the potential to create very marketable matching tumbled pairs factored into the final decision. In the end, we saw the cutting of two matching tumbled pieces for earrings plus a matching tumbled stone for a pendant, creating a suite weighing 91.10 carats total (figure 8). Multigem was also able to retrieve a lower-quality 70 ct cabochon-grade stone from the same piece of rough, making the decision to go for tumbled stones a very successful one.

Mr. Dugar said that while buying individual stones is a gamble tempered with experience and skill, buying a lot is not as risky. Many of the stones will work out as expected—some better and some worse—but in the end it will balance out for a profit.

Samit Emeralds. This company specializes in commercial-quality faceted stones. During our visit, owner Samit Bordia explained why most emerald cutting factories in Jaipur do not use high-tech equipment and computerized cutting. With stones like citrine, blue topaz, and almandine garnet, factories do incorporate automated cutting. But emerald involves so many considerations throughout the cutting process that it is not economically advantageous to use technology. The key to emerald cutting, Bordia told us, is the experience and knowledge of the cutter. That is one of the main advantages of the Jaipur industry.

At Samit Emeralds, we saw commercial-quality Brazilian and particularly Zambian rough (figure 9). Mr. Bordia buys rough from Bahia in qualities usually ranging from US$5 per kilogram to $100 per gram. We also saw some lower-quality Bahia rough selling for US$1,500 per kilo that would cut faceted stones selling to jewelry manufacturers for US$3 to $20 per carat. Mr. Bordia said that Jaipur’s emerald cutting factories usually focus on certain market sectors for finished emeralds. He noted that the quality of material from Bahia has been low, even though the quantity has been sufficient, so Samit Emeralds has not been buying heavily from Brazil.

The company purchases Zambian emerald rough from the Gemfields auctions and from Zambian miners in the town of Kitwe. Mr. Bordia has observed that approximately 90% by weight of the Gemfields auction lots are cut in Jaipur, whether the buyer is local or from the U.S. or Hong Kong.

Most of the Zambian material Samit Emeralds buys is slightly more bluish than the Bahia material, but the colors range from bluish green to slightly yellowish green. Mr. Bordia finds that the more bluish Zambian stones tend to exhibit a stronger structure when cutting, adding that they have more luster and higher clarity.

Mr. Bordia finds the assortment and grading of lots from the Gemfields auctions superior to what is offered from Bahia or from other Zambian sources, even in lower commercial qualities. Colombian rough is sometimes available in lower commercial qualities for Jaipur buyers, but comparably priced Zambian material has a better depth of color. In fact, Mr. Bordia estimates that Bahia and Zambia account for 90% of the rough cut in Jaipur, with material from Colombia, other Brazilian mining areas, Afghanistan, and Pakistan making up the rest.

The exact proportion of Brazilian and Zambian rough cut by Samit Emeralds depends on mine production. In 2012, when Bahia was enjoying a large production of good commercial-quality material, 75% of the company’s rough inventory by weight came from there. In terms of value, the proportion was 30% Bahia and 70% Zambia. The quality of Bahia emerald has been declining, so now the Zambian supply represents 90% of the value, while the weight percentages have not changed as dramatically. Mr. Bordia pointed out that many of the commercial-quality emerald manufacturers in Jaipur face the same situation.

Samit Emeralds purchases rough and produces cut stones based on customer orders for specific sizes and qualities. Like Multigem Creations, the company works with Real Gems of New York. The U.S. is an important market for Samit, with manufacturers and jewelry television networks buying the full range of their commercial-quality material through Real Gems.

As a general rule, Samit Emeralds’ planners saw or slice the stone if an inclusion occupies more than 20% of the crystal; if less, they grind the stone. Any remaining black schist is ground away after sawing. The goal is to combine maximum weight retention with maximum inclusion removal during sawing or grinding. If the emeralds are sawn, there will be pieces ready for preform and pieces that will be sawn again before preforming to remove remaining black schist or included areas.

Luster and brilliance are evaluated to decide whether the stone will be faceted or fashioned into a cabochon or tumbled piece. The sorting of facet grade versus cabochon grade versus bead or tumbled grade varies by manufacturer. Samit Emeralds tends to facet a higher percentage of lower-quality material, while some manufacturers in Jaipur have a market for very clean, high-quality cabochons, tumbled stones, and beads.

After preforming, the stones are grouped by color and clarity grades into parcels of preformed stones varying in size and shape before moving to faceting and then the final polish. For calibrated goods the preform dimensions are usually at least 0.2 mm larger than those of the finished stone. If a 6 × 4 mm oval is required, the preform size is 6.2 × 4.2 mm minimum. Mr. Bordia estimates a 30% weight loss from preform to faceted stone. Crown height and pavilion depth percentage tolerances are kept to ensure that the calibrated stones do not vary more in weight than customers will accept, while also maintaining standardized proportion appearance standards.

Over the years, Samit Emeralds has kept detailed records of all the rough lots it purchases, the preforms created, and the number of final cut stones. This has helped them estimate the weight of finished goods within a couple of percentage points for the rough lots they buy. If the weight estimation is off by more than 2%, they adjust their buying prices for the next similar lot on the market. When asked about the movement toward beneficiation and mining companies cutting their own rough to move up the value chain, Mr. Bordia felt that Jaipur’s expertise in cutting emerald and its competitive labor costs would ensure a continuous flow of rough for decades to come.

Green International. Ramdas Maheshwari of Green International estimates that 99% of their emerald rough comes from the Gemfields auctions. This second-generation company has been in the emerald cutting business for more than 40 years. Mr. Maheshwari agrees that the Gemfields auctions have changed the whole dynamic of the Jaipur emerald industry (figure 10). Since they began buying regularly at auction and receiving well-sorted and graded lots, their ability to turn over their inventory has increased by five times. Green International does not base buying and manufacturing decisions on preorders from customers. Instead, they research the kinds of goods selling in the market, buy them for the best value at auction, and cut them for the best quality and weight to sell in the Jaipur market. Their selling prices start at US$200 per carat for finished stones and can reach tens of thousands of dollars per carat. The sizes range from 2.5 mm rounds to large free-size stones.

Green’s minimum parcel for calibrated stones is about 500 carats. The percentage of calibrated goods vs. larger free-size goods they manufacture depends on what is available at auction. When the company cut Brazilian material, 90% of the manufacturing was calibrated goods. Now that they deal almost exclusively with Zambian material, they cut a higher percentage of larger free-size material. Green International also sells to manufacturers in layouts and suites, but their main customer base consists of wholesale traders from around the world.

Green International has 50 employees and does not outsource any of its cutting. Green’s experienced cutters use traditional bow-powered laps for preforming, which gives them better control of the emerald rough (figure 11) and a higher weight yield. They also like being able to feel the emerald in their hand while controlling the speed of the preform with the bow in their other hand. Green International’s cutters said they get about 2% more weight retention using the bow-powered cutting laps for preforming and hand-controlled jam pegs for faceting.

The Tanzanite Trade. When demand for emerald slowed in the latter half of the 1990s, the resilient Jaipur industry diversified into other colored stones such as tanzanite (Aboosally, 1997a). Nirmal Bardiya of RMC estimates that Jaipur cuts 90% of all tanzanites 1 gram and under (a figure confirmed by other sources), but the value percentage is smaller due to Tanzanian export restrictions that require facet-grade rough larger than 1 gram to stay in country for fashioning. When author AL visited Jaipur in 2007, a significant percentage of large, high-quality tanzanites were being cut there. At the time of our recent visit, there were more than 50 companies in Jaipur cutting tanzanite (A. Gokhroo, pers. comm., 2015). We mainly saw smaller calibrated stones, most under a carat.

The increase in gemstone sales to jewelry television networks has softened the impact of the rough restrictions, since the smaller calibrated sizes now being cut in Jaipur are a perfect match for the pieces being manufactured for television.

AG Gems. From the time it was established in 1991, AG Gems has purchased rough colored stones from East Africa. In the early 1990s, the company bought rough ruby and tanzanite in Nairobi. By the mid-1990s, AG Gems found that Arusha, Tanzania, was a better place to source tanzanite and began purchasing from dealers who bought the stones from Maasai tribesman.

Today AG Gems is one of the ten sightholders listed by TanzaniteOne, which operates in a manner similar to the De Beers supplier of choice system. For AG Gems, the fixed-price rough lots from TanzaniteOne are well graded, sorted, and organized, making it easy to calculate costs and profit margins. The company also buys an equivalent amount of rough on the open market from other miners and dealers in Tanzania. The rough supplied by Arusha’s independent dealers has become very well graded, as opposed to the mixed lots and mine runs they supplied several years ago.

AG Gems has seen wide fluctuations in supply and prices. Today’s prices are stabilized, as the miners and dealers control the material offered for sale to better meet the demand. Director Arun Gokhroo says the company’s best period in the tanzanite business was around 2012 through 2013, when Chinese demand exploded but then cooled. Now their main market is once again the United States. AG Gems sells to wholesalers and jewelry manufacturers, but perhaps their most important customers today are television shopping networks and the manufacturers that make their jewelry.

Mr. Gokhroo feels that tanzanite is now a mainstream colored stone like the “Big Three,” and although supply has fluctuated it can still meet large-scale demand. Eighty percent of the company’s business is now in tanzanite, with other Tanzanian stones like spinel, rhodolite, spessartine, and tsavorite making up the remaining 20%.

AG Gems, like RMC, has been affected by the size restrictions on rough exports from Tanzania, especially for smaller sizes, with Arusha as the cutting center for facet-grade rough over one gram. For larger rough, AG Gems and other Jaipur cutters can only obtain cabochon- or bead-quality material, which Tanzania does not subject to the same export restrictions as facet-quality material.

Mr. Gokhroo said his cutters and those of other companies in Jaipur have become expert at finding the transparent areas in these larger, lower-quality rough tanzanites and cutting faceted stones out of them (figure 12). AG Gems buys them on the open market in Arusha. These goods only yield between 2% and 5% weight retention for faceted stones, while in rough sizes under one gram they retain an average of 25% to 30% after faceting.

AG Gems primarily sells calibrated sizes, of which the most common are 4 × 6 mm to 6 × 8 mm. The smallest fancy shapes are 3 × 4 mm ovals and rounds down to 3 mm. Their customers typically allow a 0.2 mm size tolerance. Most are oval shapes, which have the best weight retention and highest demand. Most of the rough AG Gems now buys has already been cobbed in Tanzania. The rough stones are oriented for weight retention, but retaining color in small sizes is very challenging (A. Gokhroo, pers. comm., 2015).

AG Gems heat treats its rough in Jaipur. First the rough is preformed to remove potentially damaging inclusions, then heated, and then faceted and polished. Based on years of experience, the heaters can easily judge the color that will be produced. The stones are placed in a crucible inside an oven for 1.5 hours, until the oven reaches a temperature between 600° and 700°C. Then the stones are left at that temperature for half an hour, and the oven is cooled down for eight hours before removing the stones. No powders, chemicals, or fluxes are used.

From preform to calibration, the tanzanites generally lose 10% to 20% of their weight. After faceting they lose another 25% to 30%. After calibration they are usually 0.3 mm larger than the desired size, so they can lose a very slight amount of size (usually 0.2 mm) during faceting (figure 13). With the tight margins for tanzanite today, knowing how to evaluate the rough for weight retention and quality in the finished stones is critical for AG Gems.

M&M Gems. Although it specializes in cutting calibrated tanzanite and emerald, M&M Gems started cutting tanzanite in 2000. Approximately 80% of the finished stones are tanzanite and 20% emerald, but the value is a 50-50 split. At the time of our visit, the production was 150,000 stones and 25,000 carats of tanzanite a month. To give an idea of the production volume and speed, each preformer handles at least 400 stones a day (figure 14).

At the factory, we followed the entire process from rough grading and preforming to calibration and faceting. Each stone could be completed in about two hours. The smallest size of rough M&M manufactures (approximately 0.1 gram) had about 6% weight retention, while the larger sizes (1 gram) retained about 25%. Most were cut as rounds and ovals, with other shapes cut to order. As with AG Gems, their calibration tolerance is 0.2 mm.

The company buys rough from dealers in Tanzania and in the domestic Jaipur market. The supply of tanzanite has fluctuated over the years, but the focus on smaller sizes in manufacturing is due to the Tanzanian restrictions (figure 15).

For most tanzanite rough, M&M follows a heat treatment process similar to that of AG Gems, heating the rough after preforming (though we did see some lighter-color rough being heated before preforming). No time is wasted preforming material that might not have sufficient color quality for faceting, even though this leads to a higher percentage of stones that burst from preexisting fractures in the rough.

M&M classifies its tanzanite qualities according to standard terminology for the global trade. Colors are separated by tone and saturation into A, A+, AA, AA+, AAA, and the finest grade of AAA+. For stones with the same size, the spread in price from A to AAA+ can be as much as 300%. The grades are set according to M&M’s master stones, which are chosen to match the grading of global customers. Many of these customers are wholesalers, manufacturers, and jewelry television networks.

Large Manufacturers and Bead Making. Even though emerald and tanzanite are two of the most important stones commercially, the Jaipur industry cuts a wide range of material. Many varieties, including nontraditional options such as yellow scapolite, are fashioned into assorted shapes and sizes. Some of these companies operate on a massive scale, cutting the full spectrum of gems, while others specialize in a few stones based on market demand.

RMC. Since its founding in 1991 in Bangkok, RMC has been involved in cutting and trading all types of colored stones. The company now cuts in China and in Jaipur, where the main production takes place. With sales offices in Bangkok, Hong Kong, and Japan, RMC refers to itself as a supermarket for all colored gemstone needs. The company manufactures and sells more than 100 varieties of colored stones in a wide range of shapes, sizes, and qualities. It specializes in colored gemstones outside the classic “Big Three.”

RMC purchases rough colored stones from sources around the world to cut and sell in major markets. It has not ventured into finished jewelry. The company employs more than 5,400 people directly and indirectly to accommodate the huge production requirements of one million stones per month. Ninety-seven percent of its business is in cutting natural and treated gemstones, with 3% consisting of synthetics and imitations (N. Bardiya, pers. comm., 2015).

RMC produces stones in calibrated sizes (figure 16), from 1 mm rounds to 12 × 15 mm fancy shapes. Rounds usually reach 10 mm in size, and fancy shapes usually start at 3 × 4 mm. Their process involves handheld preforming and calibration machines that set the size and measurements. While RMC started out focusing on beads, today they produce mainly faceted stones.

RMC exhibits at major trade shows in China, Hong Kong, Bangkok, Japan, the United States, Switzerland, and Germany every year. Currently most of its business is in Asia. The company’s primary customers include other wholesalers, jewelry manufacturers, jewelry television networks, retail chains, and Internet retailers. The customer base has changed dramatically in the last five years.

Before 2010, RMC sold to numerous smaller companies in US$5,000 to US$100,000 orders. The consolidation of the colored gemstone industry forced many smaller companies out of business. RMC now sells to fewer companies, but these clients place larger orders. RMC finds that the smaller manufacturers and wholesale customers cannot get enough regular orders to stay in business today.

In recent years RMC has seen changes in China, its largest market. At one time, China’s appetite for colored stones caused rough prices for RMC to rise more than 300% over just a few years as demand outpaced supply from the mines. For RMC, the slowdown in the Chinese market has not caused a drop in colored gemstone prices but rather price stabilization, as demand has become more in line with supply, even though the rough supply is still very tight.

China demands bright and clean material from RMC in a variety of colored gemstones for its domestic market. RMC’s quality requirements are narrower in China than in the U.S. market. The Chinese buyers have paid strong prices to RMC for the quality they require. Japan and Europe also have more stringent quality requirements than the U.S. However, Chinese jewelry manufacturers exporting to the U.S. buy a wide range of qualities. When the U.S. market is strong, as it was during our visit, it is a great advantage for RMC, which can move all quality ranges and price points there. Meanwhile, Italian manufacturing companies are again becoming important customers.

As with other companies in Jaipur, television shopping networks from the United States, Europe, and Japan have been major buyers of colored gemstones in a wide range of sizes and qualities. RMC is focusing on television retail, which has a very fast turnover and buys in large quantities. The company can sell full productions of all sizes and qualities to a variety of shopping channels catering to different market sectors. RMC also sees potential opportunities for television retail in China, where it can sell loose colored stones directly to the Chinese shopping channels, which provide them to their own jewelry manufacturers. RMC can also supply stones to China through jewelry manufacturers in Jaipur.

Nirmal Bardiya, one of the company founders, foresees a great future for Jaipur: “The children of the leaders of the colored gemstone industry are moving toward vertical integration and up the value chain into colored gemstone jewelry manufacturing.” As Mr. Bardiya has seen the quality of cutting improve greatly over the last 10 years, opening up new markets, he has also observed dramatic improvement in jewelry manufacturing. He is investing in automation and computer-controlled cutting (figure 17) to meet the anticipated growth in demand. At the same time, he expects continued demand for Jaipur’s highly skilled but very affordable cutting labor (figure 18).

Mr. Bardiya does foresee some challenges ahead. To be more competitive with Thailand and Sri Lanka, Jaipur must improve its heat treatment technology and its skill in cutting and trading ruby and sapphire. He has also felt the effects of source-country legislation on exports of tanzanite and Ethiopian opal. While he expects such restrictions on rough exports to increase, he predicts strong growth potential throughout the Jaipur industry.

Sambhav Jewels. At the time of our visit, Sambhav Jewels was cutting apatite purchased from Madagascar (figure 19), fire opal from Mexico, morganite from Madagascar and Brazil, and chalcedony and quartz from Brazil and other sources. While the fire opal is mostly obtained in Mexico, morganite, apatite, and other gems are typically purchased from mine representatives in Bangkok.

During our visit, 80% of the production (figure 20) was for morganite and fire opal; apatite from Madagascar was also being cut, to a lesser extent. In addition, Sambhav cuts synthetics and imitations to order. We saw fire opal separated into color grades from light orangy yellow through dark reddish orange. Demand for morganite has been exceedingly strong, especially from China, and Sambhav Jewels has focused on this gemstone for the last five years (R. Jain, pers. comm., 2015).

Sambhav prefers to handle morganite, which yields around 10% weight retention as opposed to only 3% to 5% for fire opal. Fire opal also has a high rejection rate from stones becoming opaque during cutting.

For Sambhav, the Hong Kong show is the main outlet for morganite to the Chinese market, while the Tucson shows are the path to the U.S. market. There has also been strong demand from television networks, primarily in the United States, and from designers for custom orders. The orders for these television networks come mainly from jewelry manufacturers. Sambhav is also cutting moldavite and synthetic alexandrite specifically for television. It supplies on an order basis, sourcing the rough and cutting any colored stone requested by the television network’s vendors.

As with other Jaipur cutters dealing with various types of rough colored stones, Sambhav has found it difficult to source enough morganite to fill customer demand. Morganite rough has been especially difficult due to the strong Chinese demand. For instance, an order for cut stones might require 200 kg of rough, but only 100 to 150 kg of material can be sourced. Part of the difficulty in obtaining rough is that even though China is a main customer for Sambhav’s cut morganite, the Chinese cutting factories are also Sambhav’s main competitors for rough purchasing.

This imbalance in morganite rough supply vs. demand over the last five years has increased the price for Sambhav five- to tenfold. This continual price increase makes it difficult to meet the demand and price expectations of clients or to provide a stable price for customers to plan their production costs on.

Sambhav preforms and facets the morganite rough, sends out the faceted stones for irradiation to a golden color, and then heats them to pink. The final product is predominantly calibrated goods. To obtain the proper calibration size in the final faceted stone, the preforms must be a half-millimeter to a millimeter larger than the final calibrated size. For larger sizes like 10 mm rounds, the preform will be 11 mm. For a 2 mm final cut stone, the preform will be 2.5 mm. The calibration tolerance varies, with some clients allowing a 0.2 mm tolerance and others only 0.1 mm. This requires a very careful transfer from the crown to pavilion on the dop. Sambhav sells calibrated stones down to 1 mm in size as well as large freeforms, based on the order.

National Facets. Since its start in the mid-1980s, this large family-owned business has specialized in manufacturing beads. Rajesh Dhamani has been the guiding force behind the company. In the local spirit of family businesses, he is now assisted by his son Yash Dhamani, part of the new generation of Jaipur entrepreneurs.

Another member of the family, Sankalp Dhamani, explained that starting out as a bead manufacturer requires a smaller initial investment than other types of colored gemstone manufacturing. It is far less expensive to produce top-quality beads than top-quality facet-grade material. Since finding success in this niche, National Facets has also expanded into finished bead jewelry.

The company, which began with three people working out of their homes, now has a staff of 500. The commercial grades are sent to the Jaipur cottage industry, while the better-quality material is cut at the factory. More than 50 families, almost an entire village outside the city, work full-time creating beads for National Facets. Most of these families have been working for the company for over 20 years.

All of the preforms are fabricated in a factory (figure 21). The preformed stones are either cut in the factory or sent to the cottage industry with specific requirements for bead manufacture. The company also saws in the factory, drills bead holes, and does stringing. National Facets now has two factories in Jaipur, one of them in a Special Economic Zone (SEZ; see box A) to take advantage of the tax breaks for exporting.

| BOX A: SPECIAL ECONOMIC ZONES (SEZs) | ||||||||||||||||||||||||||||||||||||

As the name suggests, Special Economic Zones are located within national boundaries and dedicated to increasing foreign investments by export only. India established its first such zone in 1965. The SEZ policy announced in April 2000 provides:

|

||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||

| More than 70 companies operate their export-only business in these three zones. They employ more than 7,500 workers, a number that fluctuates seasonally. Most of the companies provide pickup and drop-off facilities for their workers at certain transit stations. The incentives and facilities offered to SEZ units include:

|

||||||||||||||||||||||||||||||||||||

Customers include other bead wholesalers. Better-quality beads often go to designers, who want rare and exotic material, as well as retail chains and high-end branded retailers. Commercial-quality goods are increasingly sold to jewelry television networks. While National Facets’ main customer base is in the United States, its beads are also selling in Germany and Japan. The company has also had some preliminary success entering the Chinese market, where customers will pay cash and give good prices. Hong Kong is one of its major outlets to markets all over the world.

More than 80% of the beads manufactured from transparent gemstones are faceted. Faceted beads are essential for television sales because their sparkle from the facets displays well on television and better captures the viewer’s attention. At any given time, National Facets is manufacturing at least 50 gemstone varieties, including ruby, sapphire, emerald, tourmaline, beryl, topaz, quartz, moonstone, opal, cat’s-eye chrysoberyl, alexandrite, tanzanite, tsavorite, and spessartine (figure 22). At the factory we saw large orders of chrysoprase and tanzanite beads totaling over 200,000 carats.

For ruby, sapphire, and emerald, National Facets looks primarily for good color and included but still transparent material, which keeps prices reasonable. For many other transparent gemstone varieties, good color and high clarity are vitally important. With transparent material, bead sizes range from 2 to 20 mm, but maximum size depends on the variety. With amethyst and citrine, high-clarity material can yield 20 mm beads, but it is very difficult to produce good-clarity morganite and aquamarine above 10 mm at a reasonable price.

Exact standardization of size and quality for specific gemstone varieties is difficult to guarantee to customers based on the supply of rough. National Facets typically informs customers how long merchandise of a particular size and quality is expected to remain in stock—usually no more than six months.

Like other Jaipur companies, National Facets must work closely with Indian customs officials to assign the right value to rough imports. While rough usually enters the country through Mumbai, it is often valued by customs officials in Jaipur, who have considerable experience with colored stones. There are no duties for rough colored stones entering India. There are some trade agreements, as with Japan, regarding the value of raw materials imported into India and the value of the finished goods exported to Japan. If the price difference is too great, the Japanese government can challenge the Indian government. Similar agreements are in place with other countries.

The company’s business strategy is to always have inventory. Even without specific orders, National Facets is constantly buying rough and cutting in order to have goods available to customers and to keep the cutters working. It tries to focus inventory on gemstone types, sizes, and qualities that are consistently in demand, like citrine and amethyst, rather than overproduce trendier bead materials like fire opal and tanzanite, which would create more pressure to sell and discount. Customers are always looking for new stones, and National Facets cuts and markets new types of beads to meet the demand without oversupplying and dropping the price.

Every time the rough goes through the saw, 5% of its weight is lost. Preforming loses on average 40%, and from preform to cutting the final bead averages about 70% total weight loss. For good-clarity material, the weight retention from the original rough is about 25% to 28%, and for lower-quality material it is 10% or less. These percentages vary by variety. For instance, chrysoprase’s weight retention is lower due to the impurities found in the rough. Good-quality quartz may go as high as 35%. Tumbled-looking material that requires only minor preforming and final polish following the preformed shape can achieve 40% to 50% weight retention, even for transparent material like aquamarine.

At full capacity, National Facets can cut up to one million carats per month, though this volume would be extremely rare due to labor costs, raw material costs, and inventory buildup. Production is gauged by market demand and availability of the right types of rough at the right price. This is a major issue for National Facets and all cutting companies in Jaipur.

In response to Tanzanian and Ethiopian regulations on rough exports, National Facets has set up cutting operations in those countries to fashion the material, with the final finishing done in Jaipur. This has created challenging situations with Indian customs officials, as there are duties on finished goods and the partially finished material must be prorated.

Gemstone Treatment. At the offices of Rhea Enterprises, Rajneesh Bhandari discussed the company’s various treated, synthetic, and imitation products. The enhancement processes include heat treatment of corundum and other gems, coatings (especially thin films on drusy quartz), fracture filling (including lead-glass filling of ruby), and stabilization of turquoise. Rhea also creates what they market as synthetic fire opal, sold under the brand name Mexifire, and manufactures imitation alexandrite plus a variety of doublets and triplets. These products are sold directly and through partnerships with other companies.

Mr. Bhandari, who has been coating gemstones since 1999, showed us the wide variety of coated drusy quartz material that is one of Rhea’s main product lines. We saw the process of cutting and shaping a natural chalcedony geode into the shapes that would be coated with materials to create the color. The final coated drusy only yields about 1% weight retention from the original geode. The gold coatings create an actual gold color, while other thin-film coatings like titanium oxide and silicon oxide cause light interference to create an assortment of colors.

Coating is done in a –7 atmosphere vacuum, by an electron beam or sputtering process. It often involves 24 to 36 multiple coatings with exact thickness, typically between 100 to 400 nm, and alternating higher and lower refractive index. A base layer is applied first and acts as an adhesive between the drusy quartz and the various color-causing elements. Slight heating is required for better adhesion. Electron beam coating can cover larger surfaces faster and more economically, while sputtering is a more adhesive process. Some of the special effects that can be created from these coatings are bicolors, matte finishes, leopard-skin patterns, and logos and other designs.

For triplets, Rhea primarily uses natural colorless quartz with a variety of colored adhesives (figure 23). Colors reminiscent of Paraíba tourmaline have proven especially popular. The company has also had success creating bicolor triplets imitating ametrine and tourmaline. The thin-film process can even be used to create a schiller effect on top of the colored coating, giving the triplets a rainbow moonstone effect. A new product we saw was a mother-of-pearl base with coloring added by the epoxy layer. Gold wires were used in the epoxy layer to create a pattern. Another interesting product was a coated drusy quartz triplet with a colorless quartz protective top. Rhea’s imitation alexandrite, a glass marketed under the trade name Alexite, features a purple to blue or an orange to green color change. In Turkey the material is sold as imitation Zultanite.

We observed the operations of Rhea’s full range of furnaces for heating corundum. The treatment factory has 14 of them, including a Sri Lankan Lakmini gas furnace and various high-temperature electronic furnaces. Rhea often heat-treats rough corundum instead of preforms since it is not focused on cutting natural corundum and finds it easier to sell the rough to cutting factories. The first furnace we saw was a Nabertherm vertical tubular furnace from Germany, which can reach temperatures around 1,900°C. The gemstones are heated in the tubular portion, which can also be used to create a vacuum for precise control of the atmosphere. Up to three gas lines can be controlled in this section. This exact control of the atmosphere is very useful in heating sapphire, where precise control over the reducing atmosphere is important.

Mr. Bhandari considers the muffle furnace more cost-effective for ruby, as the oxidizing atmosphere for heating ruby does not warrant the advanced tubular furnace. The atmosphere and environment control is highly stable even for several days of heating with the tubular electric furnace. For beryllium treatment of corundum, the advantage of the tubular furnace is its stability at high temperatures and the exact control of the oxidizing atmosphere. Mr. Bhandari notes that having exact control of the amount of oxygen allows better control over the appearance of the beryllium-diffused color, such as yellow, and the ability to make the color paler and more natural-looking.

We were told that the tubular furnace also gives precise control of the temperature, plus or minus 1°C over seven days. The atmosphere in the tube does not affect the heating elements as in a more open electric furnace like the muffle furnace. While the corundum is heated in a crucible and gases can be added to the electric muffle furnaces, the exact control of the environment is not as precise as with the tubular electric furnace. This reduces deterioration of the heating elements and makes the temperature limits higher and easier to maintain, according to Mr. Bhandari. The electric tubular furnace can also allow for more gradual cooling than Lakmini gas furnaces.

As Jaipur continues to take an even larger share of colored gemstone cutting and trading, treatment technology becomes critical. Being able to treat lower-cost goods with coatings and other processes to make them more marketable will ensure that large amounts of this material flow into Jaipur. To successfully compete with Thailand and Sri Lanka in the ruby and sapphire cutting market, Jaipur must bring its heat treatment capability up to their level.

JEWELRY MANUFACTURING, RETAIL, AND EXPORT

Over the past two decades, Jaipur has built upon a rich tradition of jewelry manufacturing that dates back to the early 1700s, when the city was founded and the maharajas encouraged the migration of skilled craftsmen to the city. The traditional artisan cottage industry was overshadowed in the twentieth century by the colored stone cutting industry, for which the city is known internationally.

Today, traditional Jaipur jewelry arts and fusion jewelry combining modern and classic styles are gaining global recognition (figure 24). Jaipur has also become a modern jewelry manufacturing hub. In the late 1980s and early 1990s, there were only four modern jewelry factories. By 2015 there were more than 250 such facilities (R. Jain, pers. comm., 2015).

We saw traditional craftsmanship using techniques dating back centuries, as well as modern mass production. Cutting-edge designer jewelry for famous brands and tremendous amounts of colored stone jewelry for television were being created. Jewelry stores that once served the maharajahs, designer brands, retailers catering to the Bollywood crowd, and vertically integrated manufacturing/retailing companies all coexist and flourish in Jaipur.

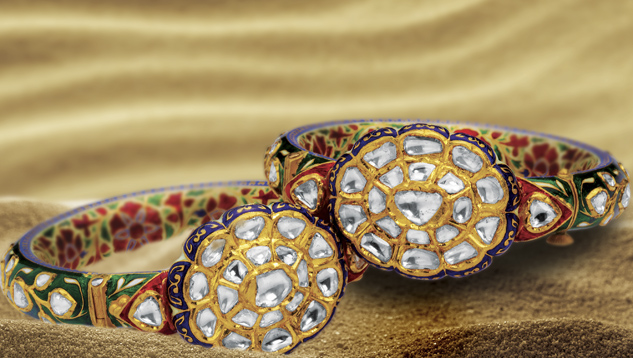

Traditional Manufacturing, Retail, and Designer Jewelry. Traditional Rajasthani jewelry can be described as an explosion of opulence and color. An abundance of large flat-shaped rough or flat-cut polki diamonds and colorful enamel jewelry, completely finished on the front and back, lends a regal appearance. These pieces are truly fit for the maharajas and moguls of the past and are completely unlike Western jewelry. Much of the manufacturing involves techniques little changed for centuries. Some traditional items of Rajasthani jewelry include the rakhdi (head ornament), tussi (necklace), baju bandh (armlet), ariya (a special necklace worn by Rajputs), gokhru (bracelet), and pajeb (anklet). For a glossary of Indian jewelry terms, see box B.

| BOX B: GLOSSARY OF TRADITIONAL INDIAN JEWELRY TERMS |

| Chambala: Bud-shaped decorations based on the yellow flower of the champa tree, strung in a series on a long necklace. Chandbala: A type of earring incorporating the shape of a half-moon. Jadau: Jewelry in which gemstones are set with gold or silver foil beneath them to enhance their brilliance. It is the oldest form of Indian jewelry and is believed to have originated in the royal courts of Rajasthan and Gujarat. Jhapta: A wedding ornament, usually crescent-shaped, that hangs on one side of the head and is fastened with a pin. Jhumki: An earring style incorporating three-dimensional ornaments around the vertical axis. Kada: A wide bangle bracelet, with or without a hinge. Kundan: A traditional form of jewelry where very thin 24K gold foil, usually pounded into long strips, is burnished around gemstones to help set them. Kundan may be used interchangeably with kundan meena, as this style of jewelry often includes enamelwork. Meenakari: A style of enameling, from meena (enamel) and kari (the art of fusing glass on precious metals). Polki: Uncut diamonds, or diamonds fashioned to resemble uncut diamonds. Rajasthani aria/ariya: A choker necklace, usually gold, embellished with polki diamonds, colored stones, and pearls. Rani Haar (also known as a Queen’s necklace): A multi-strand neckpiece with a large pendant hanging in the front. There are usually an odd number of strands, which often contain gold beads. |

So-called fusion jewelry combines the traditional materials and design elements of Rajasthani jewelry with those of various cultures and periods, including modern Western and Indian tribal jewelry. To investigate this segment of the manufacturing and retail industry, we visited four companies in Jaipur. Three dated back to the 1700s, while the fourth has only recently entered the scene, particularly with Bollywood celebrities and the international market (Jakhar, 2012).

Surana Jewellers. This family-owned manufacturing and retail business began in 1735 as a jeweler to the maharajas. The Rajasthani royalty were the core clientele for many decades, as they were among the few who could afford this jewelry. By the 1900s, wealthy British and the growing Indian merchant class had become important customers. After India gained independence in 1947, the buying power of the Rajasthani maharajas was curtailed and Surana looked to expand, traveling to jewelry shows in Mumbai, New Delhi, and other cities where they have since opened stores. Eventually the company was able to place family members in different areas of the country to open more stores, and they continue to look at new areas as the family grows.

Prior to the 1950s, selling was very informal. Showrooms had low tables, and the customer and the jeweler would sit on pillows on the floor across from one another. Structured jewelry companies were not the norm in India, and on a daily basis there were far fewer customers.

Even after Surana established its first modern showroom in 1951, it was in a 150-year-old building in the old part of the city. Their 500-square-foot showroom received five wealthy customers a day, by appointment only. There were still only about 10 customers a day for many years after that, though these were serious customers who could spend significant money (P. Surana, pers. comm., 2015).

Now there are often 60 to 70 customers a day in the larger Jaipur showroom Surana moved to in 2000; most are still serious customers looking to buy. They are the modern-day moguls: wealthy Indians, corporation heads, European royalty, and celebrities. Showrooms have a minimalist feel, which lends itself to the traditional pieces on display. The stores are organized by jewelry product categories such as gold, diamond, colored stone, enamel, and Western styles.

Kundan jewelry (figure 25) is very popular with Indian consumers living domestically and abroad. Even younger upscale Indian consumers show a serious interest in kundan jewelry. Western customers often buy kundan pieces that are relatively slender and lightweight, with a simpler design. Interest in kundan jewelry is also growing among wealthy consumers in Pakistan, Sri Lanka, Bangladesh, and Nepal, whose king is already a customer. Surana’s elaborate objets d’art in gold, polki diamonds, and enamel are found in auctions worldwide, and the collector base is growing (figure 26).

Surana also has a growing Internet sales business for its lower-priced items of US$3,000 or less while selling more expensive pieces at traditional auctions. The company exports jewelry to the large Indian customer bases in the United States, Europe, and (through Hong Kong) many other global locations. Tourists visiting Jaipur have purchased kundan-style jewelry, creating more interest globally through the pieces they bring home.

To expand its market, Surana makes elaborate jewelry for traditional Indian weddings (figure 27) as well as lines with more modern influences. Their bangle bracelets show European design influences like oval cuffs, altered for the kundan style with uncut and rose-cut diamonds and a variety of colored stones and cultured pearls. Enameling is done on the front and back of the piece. These bracelets are designed for party and evening wear as opposed to traditional wedding jewelry. Some of these high-value fashion pieces have large uncut polki diamonds.

We saw a cultured pearl and diamond necklace, designed for evening wear, with a 10 ct polki diamond as the center stone. These kundan-style pieces contain 22K, 23K, or 24K gold, which works well for the enamel used to add bright color. Polki diamonds or flat-cut diamonds are often set in the kundan style in 22K to 24K gold frames. Inside the setting, a silver foil is placed underneath the diamond to give it an appearance of depth. The diamond is then sealed in place with thin 24K gold all around it. Creating the illusion of larger, brighter polki diamonds is essential to the art of kundan jewelry.

Surana prefers 23K gold for the frames and 24K gold foil to secure the uncut diamonds in the setting. A wax-like substance holds the silver foil under the diamond, and the 24K gold foil secures the diamond. Cultured pearls and colored gemstone beads are popular components of kundan-style jewelry and are used to create a sense of movement. South Sea cultured pearls are often chosen for high-end kundan jewelry. The main stages are the creation of the gold frame, the enameling process, and the setting of the polki diamonds.

After the gold frame is made and the piece is enameled, the wax-like substance is applied to secure the uncut flat diamonds and the silver foil. After the wax-like substance becomes soft at about 60°C, they make an indentation in it, often with a rounded piece of hot charcoal, and place the silver foil and then the polki diamond. This creates the look of one piece and gives the appearance of depth to the flat diamonds that are flush with the soft wax-like material. The silver foil is shaped to act as the diamond’s pavilion. Its highly reflective nature gives the appearance of depth to the flat diamond while adding brilliance. The depth of the silver foil is determined by the stone size and the thickness of the gold frame. Surana uses a silver alloy that is approximately 8% gold so that the silver does not tarnish over time. Once the wax-like “lacquer” hardens, it puts the diamond and silver foil setting in place.

Any excess wax-like material that is pushed above the setting is removed with a graver-type tool. Then the wax-like material is reheated to 50°C, and the 24K gold foil is placed inside it and around the diamond, securing it in place. A finishing tool is used on the 24K gold, giving it a polished look. Some of Surana’s more intricate pieces can take two to four months to complete, depending on how many bench jewelers can work on different components at the same time.

Colored stones are set the same way using silver foil. Sometimes the foil is even painted to enhance the color of the stone. In less expensive kundan pieces, Surana uses 18K gold, colorless sapphires, or rock crystal quartz fashioned to resemble flat uncut diamonds (often set with silver foil behind them to increase brilliance) and no enamel. Color may be added by the use of emeralds and other colored stones.

Surana sources uncut diamonds from sightholders and specifically looks for flat rough. In one of its jewelry lines, 18K gold is used with more contemporary designs and modern-cut diamonds as well as fusion styles (figure 28). In 2013, Surana’s production of the line with modern-cut diamonds and the kundan line with uncut diamonds was divided 50-50. By 2015, the kundan-style jewelry was between 60% and 70%. This increase reflects the rising price of diamonds and the fact that foil-backed uncut diamonds offer the look of a much larger diamond for less money, which has stimulated interest in this style of jewelry. The continued rise of the wealthy class in India and the amount of money they can spend on weddings also plays a significant part. They prefer jewelry that is expensive and provides an even larger and more regal look.

Surana uses the cottage industry of artisan jewelers. Handling such expensive materials requires complete trust in the skill and integrity of these artisans, and some have been making jewelry for Surana for five generations.

Surana uses approximately 100 kilograms of gold in manufacturing each year. An elaborate bridal suite of kundan jewelry could have a total weight of half a kilogram or more, with 75% of that weight in gold. Surana Jewellers gives the material for the suite to a single artisan, who often works at home with other family members and possibly apprentices. These traditional skills and kundan-style designs are passed down from generation to generation.

Gem Palace. In the early 1700s, the ancestors of Gem Palace owner Sanjay Kasliwal were invited by Jai Singh II to Jaipur to become official royal jewelers. The family made kundan-style jewelry for the maharajas using uncut Golconda diamonds (figure 29). The opulent lifestyle of the maharajas provided a constant demand for elaborate jewelry and objets d’art, even for infants and horses. Today objects such as a 250-year-old 24K gold and enameled chess set are found throughout the Gem Palace showroom of treasures. Mr. Kasliwal showed us an infant’s solid gold plate and spoon that were enameled and set with diamonds. Some of Gem Palace’s pieces, like a 250-year-old drinking flask, have been purchased back from the descendants of the maharajas and resold to today’s ultra-wealthy.

During the British colonial period, Gem Palace served many of the viceroys in India. This eventually led to clientele like President John F. Kennedy and First Lady Jacqueline Kennedy, Queen Elizabeth II, and the royal families of the Netherlands, Sweden, and Spain. Gem Palace pieces have also been worn by celebrities past and present such as Errol Flynn, Richard Gere, Gwyneth Paltrow, and Oprah Winfrey. Some of the world’s wealthiest people, including the emir of Qatar, are clients.

Fifty percent of Gem Palace’s customers are Indian, and wedding jewelry is very important to the core business. Foreign clients from Europe, the U.S., the Middle East, and a growing market from Central and South America also play an important role.

The building that houses the showroom and workshops was completed in 1842 and still contains the room where the maharajas were received. Most of the rooms are workshops now, and Gem Palace creates its jewelry on site. The lapidary staff uses modern faceting machines as well as traditional handheld bow-powered preforming machines to cut a wide range of colored gemstones. Besides cutting for its own jewelry, Gem Palace also exports colored gemstones to other jewelers worldwide. Its jewelry manufacturing incorporates traditional hand fabrication methods and tools and even some blowtorch soldering techniques (figure 30).

Mr. Kasliwal takes pride in the fact that Gem Palace’s jewelry is finished with equally high quality on the front and back, as it was for the maharajas. This is normally done with enamel on the back. The philosophy is that the wearer sees the back of a piece as they put it on and take it off, so they should see the same quality of finish that the rest of the world sees. Mr. Kasliwal also blends styles, as in his Indo-Russian line, where the back of the piece is finished with a Russian style of filigree and diamond settings (figure 31). These new styles may incorporate flat polki diamonds, rose-cut diamonds, and modern full-cut diamonds.

Gem Palace creates jewelry for a variety of price points, ranging from US$500 to US$10 million. The company sells both antique and newly made jewelry in traditional kundan style with polki diamonds as well as variations that blend in modern influences. It also produces opulent jewelry with modern-cut diamonds and colored stones with contemporary settings, similar to what might be seen in the high-end jewelry houses of Europe. Mr. Kasliwal has also catered to a substantial increase in demand for colored stone jewelry featuring gems such as tourmaline, tanzanite, aquamarine, and quartz (Persad, 2014).

The company is vertically integrated in the sense that Mr. Kasliwal travels to Africa and South America to buy rough stones directly from the mines and the dealers. His workshop cuts the stones, designs the jewelry, and manufacturers the pieces to be sold in the Gem Palace showroom.

Amrapali Jewels. Unlike other Jaipur companies that date back to the 1700s, Amrapali Jewels was started in 1978 by two entrepreneurial history students, Rajiv Arora and Rajesh Ajmera. Both men wanted to start a business that incorporated Indian culture and history, which they found could be expressed through jewelry. They started the business with no long-term business model, just a few hundred rupees in their pockets and a passion.

The two traveled to remote villages in Rajasthan, Gujarat, and Orissa and sought out one-of-a-kind tribal jewelry to recreate in their vision. These pieces could be purchased in secondhand stores and pawnshops for very little money, often just 10% over the metal value. Much of the jewelry they created contained components of the original piece. After purchasing a necklace with 24 drop pendants, they would turn the piece into 12 earring pairs and sell to 12 customers rather than one. By following this strategy they were able to get more customers and higher profit margins. (Indeed, one of the history student founders was also a business school graduate.) Their original store in Jaipur, a 150-square-foot shop at the end of a quiet street, was the least expensive place they could find. At first the two partners made everything by hand. In 1981 they hired a craftsman, and that was the start of growing the business.

Amrapali brought the tribal motif into the realm of high-end fashionable jewelry, attracting Bollywood celebrities and other sophisticated customers. The first Mumbai store, opened at the end of the 1980s, was in an upscale shopping area that catered to a trendsetting clientele. The brand name Amrapali became synonymous with this tribal designer look. The jewelry styles remained closely related to those of each individual tribe’s unique design elements but also reflected Amrapali’s own influences. One example, the Panna collection, features carved emeralds in floral designs (figure 32).

Along with the flagship store on Mirza Ismail Road, which is considered the Fifth Avenue of Jaipur, stores were also opened in Delhi and Bangalore, and franchises were formed. Amrapali’s growing e-commerce business is designed to reach the consumer globally and directly. The export business also began growing due to strong international interest in the tribal-inspired designs. By 2002 these collections were available in Selfridges, an upscale department store in London (Kaushik, 2014). Amrapali is now sold in Harrods of London and in retail stores other than the brand’s own. There are 36 global retail outlets, 28 of them in India and eight outside the country, with an office in New York City. In addition to its own products, the company manufactures jewelry for other brands.

Most of Amrapali’s jewelry manufacturing was outsourced to artisans in the local cottage industry to meet growing demand until the company opened its first factory in Jaipur. This factory is designated as an Export Oriented Unit (EOU) within a Special Economic Zone, an area for free trade and export. The facility’s success in producing jewelry for export led to the opening of two other factories, also in Jaipur, to handle domestic demand with the same efficiency. Amrapali now relies on its own factories that, depending on the season, employ 1,600 to 2,300 craftsmen manufacturing plated base metal fashion jewelry as well as silver and gold jewelry.

Amrapali’s modern jewelry manufacturing facilities are equipped with everything needed for mass production of a variety of traditional and fusion jewelry. Manufacturing includes hand fabrication and stone setting as well as massive amounts of wax carving, casting, and plating.

While documenting Amrapali’s manufacturing processes, we saw how the company handles its jewelry lines. Traditional kundan jewelry was manufactured in a separate area of the factory that produces fusion and more modern styles. Amrapali uses traditional steps, including design sketching, hand fabricating the 22K to 24K gold frames, placing the wax-like substance in the frame, placing the polki diamonds and setting them with the 24K gold foil, and applying the enamel (figure 33).

Fifteen years ago, 60% to 70% of Amrapali’s business was in exports, but today that number represents the company’s domestic sales. The growing discretionary income and purchasing power of the Indian consumer as well as the number of points of sale throughout India have led to this change. With the challenging global economic conditions over the last several years, the international sales volume has actually increased through lower-priced pieces, including base metal fashion jewelry and silver jewelry, which is less expensive and easier to sell and often has a higher profit margin. Amrapali’s silver jewelry often contains lower-priced colored gemstones, and the base metal jewelry incorporates crystal and other imitations. The e-commerce site mainly sells silver jewelry domestically and fashion jewelry globally, although the company recently launched a base metal fashion jewelry line for Indian consumers. Online sales represent 35% of Amrapali’s international sales by value. There are fewer e-commerce purchases internationally than domestically, but often the overall purchase price is higher. This is partly because shipping costs make smaller purchases less cost-effective. But the domestic e-commerce customer is a very loyal repeat customer.

During festival seasons in India, Amrapali’s sales can increase dramatically. The company finds that Indian consumers are becoming more fashion conscious. They want to change their jewelry more often and wear new jewelry for special occasions. The price point of the less expensive but well-made and trendy jewelry makes it attractive to consumers with this new mindset.