Two Large CVD-Grown Synthetic Diamonds Tested by GIA

The quality and size of near-colorless and colorless synthetic diamonds grown by chemical vapor deposition (CVD) have rapidly improved in recent years due to advances in growth techniques and the introduction of post-growth decolorizing treatments. Near-colorless CVD synthetics have now passed the three-carat threshold. In September 2015, a 3.09 ct sample (I color, VS2 clarity) of unknown provenance was submitted to HRD Antwerp. This was preceded by Pure Grown Diamonds’ announcement of a 3.04 ct synthetic (I color, SI1 clarity) in December 2014.

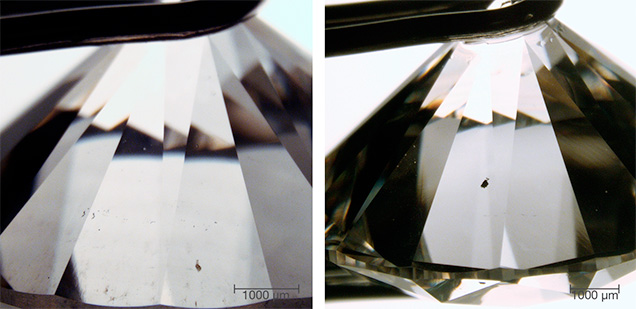

GIA’s New York laboratory recently tested two large CVD synthetic diamonds (figure 1) submitted for grading services. These synthetics, weighing 2.51 and 3.23 ct, are the largest CVD-grown diamonds GIA has examined to date. The results of the examination underscore the continued improvements in CVD synthetic diamonds.

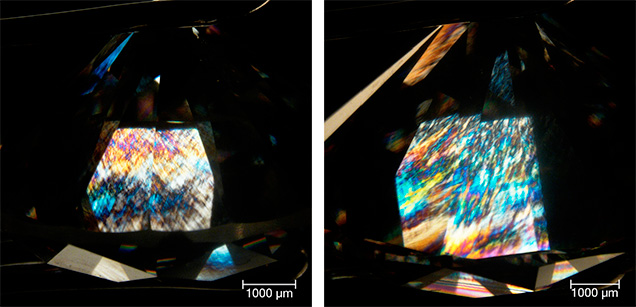

The 2.51 and 3.23 ct round brilliants received H and I color grades, respectively. Microscopic examination revealed pinpoint and black inclusions in both, while small fractures along the girdle were only observed in the 2.51 ct round (figure 2). The 3.23 ct synthetic contained a small black inclusion measuring approximately 125 µm. As a result, SI1 and VS2 clarity grades were given to the 2.51 and 3.23 ct samples, respectively. Both revealed irregular stress patterns with high-order interference colors when viewed under cross-polarized light (figure 3), indicating high levels of strain.

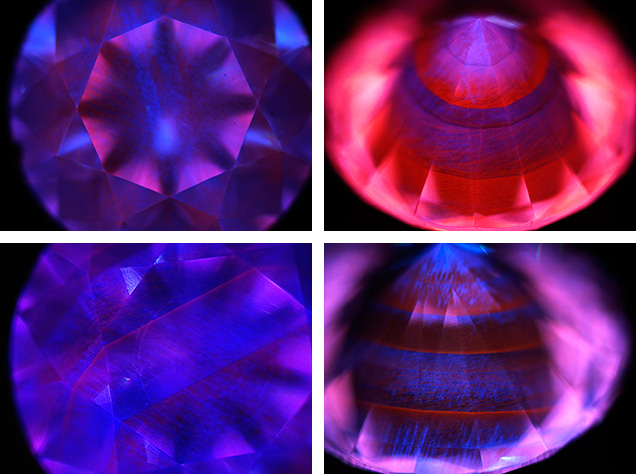

The synthetics showed weak orange fluorescence to conventional short-wave UV and were inert to long-wave UV radiation. Exposure to the deep UV radiation ( 230 nm) of the DiamondView revealed an overall strong red-pink fluorescence attributed to nitrogen-vacancy centers with dislocation bundles that fluoresced violet-blue (figure 4), followed by weak greenish blue phosphorescence. Both samples were characterized by a layered growth structure, suggesting that the crystals were grown using a multi-step technique to maximize their volume. The sharp boundaries between the different growth layers are a result of changes in the fluorescent impurity uptake during the starting, stopping, and restarting of growth. These images clearly revealed that at least five growth layers were applied to produce these large crystals. The patterns suggest that the table of the 2.51 ct samples was cut parallel to the growth layers, while the table of the 3.23 ct synthetics was cut at an angle to the growth layers. The dislocation bundles are seen to propagate through the different growth layers. The formation of the two blue bands of highly concentrated dislocations crossing the table of the 2.51 ct specimens is not understood.

Infrared absorption spectroscopy in the mid-IR range (6000–400 cm–1) showed no major nitrogen-related absorption in the one-phonon region, which classified both samples as type IIa. No hydrogen-related defects were detected, either. UV-Vis-NIR absorption spectra collected at liquid-nitrogen temperature revealed a smooth increase in absorption from the infrared region to the high-energy end of the spectrum, with a 737 nm peak in both samples and a small absorption peak at 596 nm in the 3.23 ct synthetic. The 737 nm peak is an unresolved doublet at 736.6/736.9 nm attributed to [SiV]–. This center is often inadvertently introduced during CVD growth (P. Martineau et al., “Identification of synthetic diamond grown using chemical vapor deposition (CVD),” Spring 2004 G&G, pp. 2–25; W. Wang et al., “CVD synthetic diamonds from Gemesis Corp.,” Summer 2012 G&G, pp. 80–97) but is rarely observed in natural diamonds, especially using absorption methods. The 596 nm feature is particularly useful for identification purposes, as it has only been reported in CVD synthetic material (Martineau et al., 2004).

Photoluminescence (PL) spectra acquired with 514 nm laser excitation at liquid-nitrogen temperature revealed a doublet at 596/597 nm, nitrogen-vacancy centers at 575 [NV]0 and 637 [NV]– nm, and [SiV]– at 736.6/736.9 nm for both samples, with the [NV]0/– luminescence dominating. The strength of the [NV]0/– centers was consistent with the red-pink fluorescence colors (figure 4). Although the 596/597 nm doublet is not thought to arise from the same center as the 596 nm feature seen in the absorption spectrum of the 3.23 ct sample, it has only been detected in CVD synthetics, thus revealing the samples’ CVD origin (Martineau et al., 2004). The doublet also indicated that the samples had not undergone post-growth HPHT (high-pressure, high-temperature) processing to improve their color, as the treatment would have removed this feature.

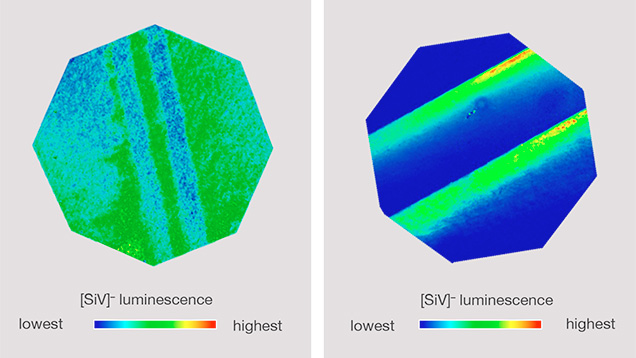

The distribution of [SiV]– centers was investigated through PL mapping of the 736.6/736.9 nm doublet at liquid-nitrogen temperature using 532 nm laser excitation (figure 5). The distribution was different between the two samples, forming patterns that corresponded directly with their DiamondView images (figure 4). For the 2.51 ct sample, the [SiV]– luminescence decreased along the bands with higher concentrations of dislocation bundles. This may indicate that there are fewer [SiV]– centers in this region, or an increased concentration of defects (either structural or impurity-based) that effectively quench the [SiV]– luminescence. Where the growth layers intersect the table in the 3.23 ct sample, the [SiV]– luminescence appeared to be highest at the start of a layer’s growth, decreasing as the growth progressed. This could mean that the concentration of silicon in the growth gas fell over time, or that the concentration of defects that may quench the [SiV]– luminescence increased during growth. Notably, the concentration of dislocations increased as growth progressed.

Analysis of these two large samples demonstrates that high-quality CVD synthetic diamonds can be produced even without post-growth decolorizing HPHT treatment, marking a significant improvement in CVD growth. Using advanced spectroscopic and fluorescence imaging technologies, it is nevertheless possible to detect low concentrations of impurity centers, allowing conclusive determination of these samples’ synthetic origin. GIA is monitoring the development of laboratory-grown diamonds and conducting research to ensure that we can continue identifying every single synthetic diamond.