Laboratory-Grown Diamonds: An Update on Identification and Products Evaluated at GIA

ABSTRACT

Over the past two decades, GIA has documented a rapid evolution of laboratory-grown diamonds; this article provides a comprehensive overview of these developments and summarizes novel laboratory-grown diamonds that may become more common in the future. The industry has seen a significant increase in the quantity, size, and quality of laboratory-grown diamonds, making them viable for commercialization on a larger scale. Nevertheless, there have been relatively few changes in laboratory-grown diamonds during the last five years, indicating that developments have largely stabilized for now. This overview summarizes the two diamond growth processes: high-pressure, high-temperature (HPHT) and chemical vapor deposition (CVD). It explores the major trends observed by GIA since 2007, the year it began issuing synthetic diamond grading reports. CVD products now dominate the supply of laboratory-grown diamonds submitted for grading reports, with the majority of these also undergoing post-growth HPHT treatment to remove their color. This article discusses methods and strategies for identifying laboratory-grown diamonds by providing their distinguishing gemological characteristics as well as results from recent developments in advanced testing approaches.

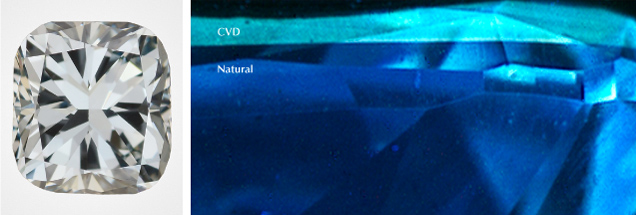

The introduction of laboratory-grown diamonds to the consumer market has expanded the variety of products available but also increased the complexity of identification for many in the trade. Laboratory-grown diamonds that are colorless to near-colorless share many gemological and physical properties with their natural counterparts (figure 1), which presents a challenge for independent gemologists and appraisers in distinguishing these gems from natural diamonds. Consequently, gemologists have needed to invest in powerful analytical testing equipment or depend on gemological laboratories for accurate identification.

Colorless to near-colorless laboratory-grown diamonds are type II, meaning they have no detectable nitrogen impurities (Breeding and Shigley, 2009). By contrast, only about 1% of natural diamonds are type II (Smith et al., 2016; Eaton-Magaña et al., 2020). Despite the increasing prevalence of laboratory-grown diamonds within the trade, their volume remains small compared to that of natural diamonds submitted for grading. Therefore, only those diamonds that test as type II require extensive analysis to determine whether they are laboratory-grown. These can be produced by high-pressure, high-temperature (HPHT) or chemical vapor deposition (CVD) processes.

This study summarizes the wide range of laboratory-grown diamonds submitted to GIA over the years, allowing these stones to tell the story. Over the past 20 years, advances in diamond growth processes have substantially altered the color and size of gem-quality stones submitted to GIA. In addition, this survey emphasizes some new laboratory-grown products that could become more common in the future.

OVERVIEW OF LABORATORY-GROWN DIAMOND MANUFACTURE

Although the mechanisms for laboratory growth of diamonds are well established (e.g., Eaton-Magaña and Shigley, 2016; Eaton-Magaña et al., 2017; D’Haenens-Johansson et al., 2022), this article provides a brief summary of the CVD and HPHT growth processes. For both methods, a diamond substrate (often referred to as a “seed” in HPHT growth) is used to create the crystal blueprint from which the new diamond is created. The quality, size, and preparation of the substrate can have a significant impact on the resulting diamond (D’Haenens-Johansson et al., 2022). Substrate availability—previously a limiting factor for commercial production—has dramatically improved to meet demand.

A report by Bain & Company (Linde et al., 2021) estimated that 6–7 million carats of gem-quality laboratory-grown diamonds were produced globally in 2020. China led the way with approximately 3 million carats (mostly grown using HPHT), followed by India with about 1.5 million carats (mostly CVD) and the United States with about 1 million carats (CVD). Laboratory-grown diamond production has continued to expand as public perceptions of its use in jewelry have evolved. In October 2021, industry analyst Paul Zimnisky estimated that laboratory-grown diamond jewelry accounted for approximately 3.4% of the global diamond jewelry market by value in 2018. He forecast an increase to 7.5% in 2021 and 11.5% by 2025. In January 2024, he revised the 2025 projection to ~20% (Zimnisky, 2021, 2024).

HPHT-grown diamonds are the market leaders in China, including the mass production of small, melee-size goods by both private and government-funded companies such as Zhengzhou Sino-Crystal Diamond Co., Zhongnan Diamond Co., and Henan Huanghe Whirlwind Co. (Linde et al., 2021). HPHT technology has long been used to manufacture diamond grits and powders for the abrasives industry, setting the stage for the rapid development of gem-quality materials. Chinese CVD producers have also demonstrated the ability to grow high-quality gemstones. Shanghai Zhengshi Technology Co. produces large, untreated colorless CVD-grown diamonds (Myagkaya and Johnson, 2021; Wang et al., 2022), while Ningbo Crysdiam Technology Co. creates colorless, pink, and blue CVD products (Lu et al., 2019).

India’s output of laboratory-grown diamonds using the CVD method has accelerated dramatically in recent years, supported by an estimated 4,000–6,000 CVD reactors (Rego, 2023). Many of these manufacturers are based in Surat in the state of Gujarat, which is also the world’s leading diamond cutting and polishing center. Ethereal Green Diamond produces CVD-grown diamonds in very large sizes, including the largest faceted example to date, a 75.33 ct square emerald cut displayed at the 2024 JCK Las Vegas show. The crystal from which it was fashioned reportedly took nine months to grow (Ord, 2024). Greenlab Diamonds attracted global attention when Indian Prime Minister Narendra Modi presented one of their CVD-grown products to First Lady Jill Biden during a 2023 visit to the White House. This 7.50 ct F-color, VVS2-clarity diamond was faceted from a 17 ct crystal that took 40–45 days to synthesize (Fedow, 2023). The 75 ct and 7.50 ct weights for these CVD-grown diamonds were both intended to commemorate the 75th anniversary of India’s independence. This high-profile gift demonstrated the dramatic change in attitudes toward laboratory-grown diamonds in recent years.

CVD diamond production in the United States arose as a byproduct of the semiconductor industry, which harnessed them for a range of technological uses. Indeed, diamond’s remarkable combination of properties—high hardness, high thermal conductivity, low thermal expansion, wide optical window, biocompatibility, and high resistance to corrosion, acid, and radiation—has sparked a wide range of engineering applications (e.g., De Wit, 2018; Markham and Twitchen, 2020). Some of the players that produce both engineering-related and gem products have included Washington Diamonds, Diamond Foundry, and Plasmability.

CVD Growth. CVD diamond growth is based on a gas-phase chemical process that bears almost no resemblance to natural diamond formation. This technique involves a reactor in which hydrogen and hydrocarbon (typically methane) feed gases flow over one or more diamond seeds. Microwaves are used to activate a plasma, creating a mixture of molecular, radical, and ionic species that are involved in a series of reactions necessary to deposit diamond material on the seeds. Hydrogen, accounting for 90–99% of the gas mixture, suppresses the growth of graphite or non-diamond carbon, which would hinder high-quality diamond formation.

For many decades after the first growth of CVD diamond in 1952, the crystal quality and sizes were not suited for gem applications. Only limited quantities of these diamonds were available in the early 2000s (Wang et al., 2003, 2005, 2007; Martineau et al., 2004; Angus, 2014). Since then, there have been notable improvements to CVD growth techniques (e.g., Butler et al., 2009; Liang et al., 2009; Nad et al., 2015, 2016; Tallaire et al., 2006, 2017), which have yielded substantial amounts of high-quality CVD-grown gem diamonds (e.g., Wang et al., 2010, 2012; Linde et al., 2021; Smith, 2023), including the large specimens mentioned earlier.

HPHT Growth. The HPHT method mimics some of the essential conditions under which natural diamonds form. A solid carbon source, typically graphite powder, is subjected to pressures of 5–6 GPa (equivalent to a depth of 150–190 km within the earth) and temperatures of 1300–1600°C. These temperatures are higher than those for natural diamond formation of ~1040–1250°C (Stachel and Luth, 2015), allowing for rapid growth. HPHT growth takes place inside a capsule that includes the carbon source, a metallic flux for dissolving the carbon to aid in growth, and a diamond seed to initiate the process (Stoupin et al., 2016; Tallaire et al., 2017; D’Haenens-Johansson et al., 2022). The diamond seed is at a lower temperature, so that carbon supersaturates and crystallizes out of the metal solution. An HPHT-grown diamond can usually be grown in a time frame ranging from an hour to a few weeks, depending on the desired size and quality (Sumiya et al., 2015; D’Haenens-Johansson et al., 2015a).

While the CVD method was developed earlier (Angus, 2014), the first gem-quality laboratory-grown diamonds were produced using the HPHT method (Shigley et al., 2002, 2004). Most early HPHT products had saturated fancy colors, often yellow-orange or yellow due to isolated nitrogen impurities or blue due to boron. Over the past 10–15 years, there has been a significant shift toward colorless to near-colorless products (D’Haenens-Johansson et al., 2014; Eaton-Magaña et al., 2017). Additionally, large HPHT-grown diamonds have been created, with Meylor Global reporting crystals surpassing 100 ct in size produced by Alkor-D (“Meylor Global…,” 2020; D’Haenens-Johansson et al., 2022). The largest recorded laboratory-grown diamond is a 150.42 ct HPHT-grown crystal (28.55 × 28.25 × 22.53 mm) with good quality, created in November 2021. To date, there are no documented reports of faceted HPHT-grown diamonds larger than 100 ct.

DISTRIBUTION OF QUALITY FACTORS AMONG LABORATORY-GROWN PRODUCTS

GIA maintains a comprehensive database of all types of gemstones submitted to the laboratory, including natural, treated, and laboratory-grown diamonds, both fancy-color and colorless. This resource provides a unique opportunity to review historical data and analyze submission trends over time. The results of GIA’s examination of tens of thousands of HPHT-grown and CVD-grown diamonds are documented in figures 2–6 and box A. These include updates to articles that discussed data from years prior (Eaton-Magaña and Shigley, 2016; Eaton-Magaña et al., 2017, 2021b).

GIA has documented the color distribution of CVD-grown diamonds per year (figure 2). Throughout the first decade of the 2000s, CVD submissions to GIA were relatively low, so the submissions for some years had to be aggregated graphically. For many years, most samples were “near-colorless,” with color grades from G to N. Prior to 2020, only a small percentage of CVD submissions had colorless grades (D, E, or F). However, 2020 saw a significant increase in the submission of colorless CVD-grown diamonds, likely due to improvements in growth and treatment procedures by established diamond manufacturers and the emergence of additional growers with new approaches. Moreover, a significant number of CVD-grown diamonds during the mid-2010s were observed to have a gray coloration (e.g., Ardon and Eaton-Magaña, 2014), possibly produced unintentionally through defect contamination during growth—an effect that may be even more evident following the annealing treatments commonly used to decolorize brown-hued CVD-grown diamonds. Gray color in CVD-grown diamonds has been linked to the presence of non-diamond inclusions referred to as “carbon nanoclusters,” whose introduction is affected by growth conditions (Zaitsev et al., 2020). The conditions causing gray-colored CVD-grown diamonds have been mostly eliminated, as these stones are no longer being produced and submitted. These trends indicate that manufacturers are constantly—and successfully—refining their growth and treatment procedures to produce large, colorless diamonds in response to consumer tastes.

The color distribution of HPHT-grown diamonds over the years (figure 3) is much different. Most early HPHT-grown diamond submissions, starting with the introduction of synthetic diamond reports at GIA in 2007, were yellow-orange (e.g., Shigley et al., 2004). With advances in HPHT growth processes, manufacturers successfully eliminated nitrogen from the lattice in growing diamonds—the main cause of their yellow-orange color. There has since been a sharp decline in submissions of yellow-orange HPHT-grown diamonds. Colorless samples now represent the vast majority of submissions, particularly in the years 2021–2023, when >90% of HPHT-grown diamond intake was colorless—a trend that likely reflects consumer preferences.

The size of gem-quality CVD-grown diamonds has seen a dramatic increase over time. There has been a consistent trend toward larger sizes (figure 4). In the first decade of the 2000s, most CVD-grown diamonds submitted to GIA were under half a carat. Today, the majority of them exceed 3 ct. This change in size reflects improvements in CVD methods as well as the availability of large diamond substrates. Figure 5 shows milestones in record size for CVD-grown diamonds, illustrating the rapid evolution in gem-quality CVD growth. Starting from 2003, when GIA received its first faceted CVD-grown diamond for research purposes, specimens remained small (and mainly brown) until about 2010 (Wang et al., 2007, 2010). The years since then have seen a very rapid increase in size. By January 2022, the largest faceted CVD diamond was 16.41 ct (Wang et al., 2022). Since that time, the benchmark has more than quadrupled to 75.33 ct. Now that manufacturers have demonstrated the ability to produce large CVD-grown diamonds, future production will be guided by demand and profitability.

Figure 6 shows the annual weight distribution of faceted HPHT-grown diamonds. The majority of the larger HPHT-grown diamonds were in the less-marketable yellow-orange color range. The growth of large, colorless HPHT-grown diamonds with high purity is particularly challenging, as it requires complex ingredient and recipe development to minimize nitrogen incorporation, as well as the ability to carefully control conditions over extended periods (D’Haenens-Johansson et al., 2022). Nitrogen has a catalytic effect on diamond growth, so its absence reduces growth rates. Whereas CVD diamonds can be created over a series of growth steps, alleviating some process control requirements, HPHT-grown diamonds are produced in a single uninterrupted run. Since 2016, there has been a shift toward colorless material (figure 3) and an increase in size, with the majority exceeding 2 ct (figure 6).

Figure 7 shows the cumulative submissions of HPHT- and CVD-grown diamonds to GIA since 2007, when GIA began receiving them. This figure indicates that the vast majority of both HPHT- and CVD-grown diamond submissions have been since 2021. Initially, most of these were created using the HPHT method. Over the ensuing years, however, the CVD population consistently increased and eventually outnumbered HPHT-grown submissions by around 2016. At present, GIA averages more CVD-grown diamond submissions per day than it once did during an entire year.

Some CVD-grown diamonds have a brown coloration after growth, associated with the presence of vacancy clusters and/or nitrogen-related defects (Barnes et al., 2006; Jones et al., 2007; Mäki et al., 2007; Khan et al., 2013; Zaitsev et al., 2020, 2021). As with natural brown diamonds (e.g., Fisher et al., 2009), CVD-grown diamonds can be enhanced using HPHT treatments to reduce or remove the brown coloration (Wang et al., 2003, 2012; Charles et al., 2004; Mäki et al., 2007). Although similar equipment can be used for HPHT treatment and HPHT growth, it is important to note that the underlying methods are distinct. Furthermore, HPHT treatments are conducted at higher temperatures than those used for HPHT growth (>1600°C) and do not result in the synthesis of additional diamond material. Low-pressure, high-temperature (LPHT) treatment, in which samples are annealed at similarly high temperatures under vacuum or an inert gas, can also be used to change the color of CVD-grown diamonds (Meng et al., 2008; Liang et al., 2009; Johnson et al., 2023). Manufacturers of CVD products can thus use recipes that promote rapid growth of diamond layers, even if it results in a brown coloration, and subsequently improve the color grade through post-growth annealing. This approach may be faster, easier, or more cost-effective than directly producing a colorless diamond using CVD. Over time, there has been a consistent increase in the percentage of CVD-grown diamonds exhibiting signs of annealing treatment (Eaton-Magaña et al., 2021b). Since 2020, approximately 80% of the CVD diamonds submitted to GIA have undergone post-growth processing.

IDENTIFICATION AND MELEE DIAMONDS

The gem trade has been facing challenges in identifying laboratory-grown diamonds due to the rapid increase in production as well as mixing (both accidental and intentional) with natural diamonds. While HPHT and CVD growth processes have been refined, many of the gemological criteria and strategies have remained consistent. Prior publications have documented the detailed gemological characteristics of HPHT- and CVD-grown diamonds (e.g., Eaton-Magaña and Shigley, 2016; Eaton-Magaña et al., 2017; D’Haenens-Johansson et al., 2022), and the reader is referred to those review articles for details on gemological characteristics. The conclusive identification of a laboratory-grown origin typically requires a combination of gemological features, yet simple visual inspection can still be valuable. For instance, a “LABORATORY-GROWN” inscription or manufacturer-specific marking to support transparency and traceability is commonly found on the girdle of commercial-size products.

Although certain gemological features strongly suggest a laboratory-grown origin, there are exceptions due to the wide range of growth recipes and treatments. Phosphorescence—the emission of light from a sample after exposure to UV—is often used as a key indicator for colorless and near-colorless HPHT-grown diamonds, which generally exhibit intense, long-lived blue-green phosphorescence. Only a few natural type IIb diamonds and some CVD-grown diamonds exhibit a comparable reaction. However, low-dose irradiation can reduce or eliminate the phosphorescence response in HPHT-grown diamonds, as initially reported by Robinson (2018) and confirmed by subsequent experiments (e.g., figure 8 and Gao et al., 2021). Relying on a phosphorescence observation or any other single gemological observation in testing colorless HPHT-grown diamonds is not advisable.

Melee Diamonds. Identifying melee-size diamonds as laboratory-grown presents a particular challenge. Due to their small size, they are difficult to handle and not suited for testing using certain laboratory instruments; they also require higher magnification for detailed microscopic inspection and often lack markings from a manufacturer or gemological laboratory (Choi et al., 2020). A tiny melee stone can take two to three times longer to analyze than a half-carat diamond. Most melee-size laboratory-grown diamonds come from manufacturers in China, where the HPHT growth method is preferred for growing small diamonds economically, allowing the simultaneous production of thousands of nearly colorless diamonds using microscopic seed crystals.

Given the small size and abundance of melee, screening instruments are particularly important in analyzing them. But because there are significant differences between HPHT and CVD growth methods, as well as various types of post-growth treatment, there is no cost-effective or rapid screening tool that can definitively identify all laboratory-grown diamonds. Instead, the majority of screening tools available in the consumer market provide a “pass” or “refer” result for colorless to near-colorless diamonds (Tsai and D’Haenens-Johansson, 2019), with “pass” indicating the test sample is natural. Diamonds that produce a “refer” result may be natural or laboratory-grown. These require further testing for conclusive identification, which involves a combination of gemological techniques or examination by a laboratory (e.g., D’Haenens-Johansson et al., 2022). Depending on the method of testing, some screening devices may not be able to refer simulants, incorrectly passing them as natural. Users must understand a screening instrument’s scope and limitations (e.g., color range, size, and simulants). The Natural Diamond Council reports on independent testing of popular screening equipment under the ASSURE program (Natural Diamond Council, 2023).

Many screening approaches for colorless or near-colorless diamonds are based on the diamond’s type. Diamond type, as described by Breeding and Shigley (2009), is a valuable classification for scientific analysis. To summarize briefly, a type II diamond contains no nitrogen detectable by infrared (IR) spectroscopy, while a type Ia diamond shows the presence of aggregated nitrogen. Figure 9 illustrates the clear differences between natural type Ia and laboratory-grown type II diamond populations. The overwhelming majority of natural diamonds in the D to N range are type Ia, while all colorless laboratory-grown diamonds are type II. This distinction provides a solid basis for various screening approaches and an efficient first step in the identification process. However, there are some caveats to advanced testing, which will be discussed in the next section.

ADVANCED TESTING CHALLENGES AND NEW TECHNIQUES

CVD-grown diamonds often have distinctive gemological and spectroscopic features that make their identification straightforward using the tools available in a gemological laboratory (e.g., Eaton-Magaña and Shigley, 2016; D’Haenens-Johansson et al., 2022). This section will discuss some of the current challenges with advanced testing, as well as additional spectroscopic and imaging instrumentation used.

The spectroscopic characteristics of laboratory-grown diamonds, especially the defects identified through photoluminescence (PL) spectroscopy, have been thoroughly documented (Wang et al., 2012; D’Haenens-Johansson et al., 2014, 2022; Eaton-Magaña and Shigley, 2016).

The silicon vacancy (SiV–) peak at 736.6/736.9 nm has long been a consistent indicator of CVD-grown diamonds. Silicon incorporation is often caused by accidental doping due to silicon-containing components such as quartz windows in the reactor chamber. However, silicon-related defects are also detected occasionally in natural diamonds (Breeding and Wang, 2008; Lai et al., 2020). Furthermore, an increasing number of CVD-grown diamonds do not exhibit detectable SiV– peaks in their PL spectra. In recent years, the GIA laboratory has noticed a higher percentage of CVD-grown diamonds that have only a very weak or undetectable SiV– feature in the PL spectra. Through the years, there has been a pronounced decrease in SiV– intensity when detected (figure 10A). In the future, the absence of a detectable SiV– peak could become more common in CVD-grown diamonds, reducing its value as a diagnostic feature.

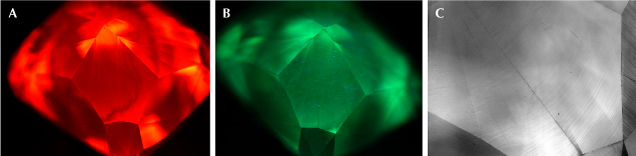

Similarly, the fluorescence of CVD-grown diamonds when excited by deep UV using the DiamondView instrument (excitation wavelength <225 nm; Welbourn et al., 1996) is often very distinctive and recognizable. Growth layering, corresponding to defects at growth interfaces, is commonly visible when a diamond is exposed to deep UV (e.g., figure 11, top left). Recently, however, we have seen some examples of CVD-grown diamond that do not exhibit traditional features and patterns (e.g., Eaton-Magaña and Shigley, 2016; D’Haenens-Johansson et al., 2022). Instead, they display a fluorescence that closely resembles what we often see in type II natural diamonds (figure 10, B and C). The ambiguity of deep-UV fluorescence patterns occasionally requires the use of more specialized imaging technologies such as cathodoluminescence (CL) imaging. While CL imaging is not commonly applied even at gemological laboratories, it has successfully revealed growth features diagnostic of CVD growth that were not reliably identified with deep-UV imaging alone (figure 12).

Recently, several new analytical techniques have emerged. Photoluminescence mapping enables the rapid collection of PL spectra across a diamond’s surface, generating a map of PL intensities (Eaton-Magaña et al., 2021a). This method can automatically collect thousands of spectra in situ for a crystal in less than 10 minutes while the stone is held at liquid nitrogen temperature (–196°C). The size of each pixel in the collected spectrum can be as small as a few microns, enabling the determination of PL spectra and diamond defects at the micron scale.

For example, silicon-related defects are commonly introduced in CVD-grown diamonds by plasma etching of reactor components (Robins et al., 1989; Barjon et al., 2005). The negatively charged SiV– defects emitting at 737 nm can be easily detected by PL, and their distribution can reveal changes in growth conditions. In a CVD-grown diamond produced using a series of growth steps, these interruptions lead to distinct spatial differences in SiV– concentration (figure 11, top) that reflect the layered growth of CVD diamonds. These variations may be more pronounced than for other commonly observed defects such as nitrogen vacancy (NV) centers.

PL mapping can also reveal the distinctive cuboctahedral growth pattern in HPHT-grown diamonds, in which SiV– defects are confined to the octahedral {111} growth sectors. PL mapping of various other defects in both CVD- and HPHT-grown diamonds has also been reported (e.g., Loudin, 2017; Eaton-Magaña et al., 2021a). Given the heterogeneity of defects in the diamond lattice for some stones, PL mapping offers advantages over single-point analyses using traditional, non-mapping PL spectroscopy. PL mapping can show the impurity distribution and growth pattern and, with thousands of spectra collected, increases the probability of defect detection compared to a single-point PL spectrum.

Despite the changes in laboratory growth processes and post-growth treatments over time, the combination of distinguishing features can still confirm a diamond’s natural or synthetic origin. This reinforces the importance of not relying on only one gemological or spectroscopic feature. Instead, it is essential to evaluate a range of characteristics.

UNCONVENTIONAL LABORATORY-GROWN DIAMONDS

With the influx of laboratory-grown diamonds submitted to gemological laboratories in recent years, we have been able to observe a subset of products that are atypical. Many of these appear to be experimental prototypes created by a combination of novel growth and/or post-growth treatment methods made possible by readily available and inexpensive laboratory-grown material. We have collected several examples of uncommon laboratory-grown diamonds submitted to GIA, some of which may become more prevalent in the future.

CVD Overgrowth on Natural Diamonds. In 2017, GIA encountered the first client-submitted CVD overgrowth on a natural faceted gem diamond (also called a “hybrid”) (Moe et al., 2017; see figure 13, left). With these hybrids, the manufacturer places a natural diamond in the CVD reactor as the seed plate rather than a CVD-grown or HPHT-grown diamond, which is standard for the CVD process. Both the seed and the overgrowth layer are retained in the faceted gem. CVD overgrowth diamonds are generally designed to add weight or produce a different color. The overgrowth described in Tang et al. (2018) successfully increased the weight of the original diamond such that the 0.11 ct finished gem hybrid diamond was 64% CVD-grown. Other hybrid diamonds reported were generated with the intent to achieve a fancy blue color (Fritsch and Phelps, 1993; Moe et al., 2017; Ardon and McElhenny, 2019).

The CVD overgrowth layer has a limited thickness when deposited on a faceted natural diamond. In order to reduce non-diamond carbon formation during the CVD process, seed plates are often cut within 2° of the cubic {100} direction (Berdermann et al., 2004). The faceted diamond surfaces would deviate significantly from the desired {100} direction, limiting the potential thickness of a deposited CVD layer. Only a small amount of weight can be added, and the table facet is the most likely growth face for these cases of CVD overgrowth (Tang et al., 2018).

To achieve a blue color with a boron-doped CVD diamond overgrowth, only a thin film (<0.1 mm) is needed to significantly influence the stone’s color. The deep-UV fluorescence image in figure 13 (right) shows a marked color change at the interface between the natural diamond substrate and the CVD overgrowth layers, resulting in a Fancy grayish greenish blue color (Ardon and McElhenny, 2019). Only a small number of these CVD overgrowth diamonds have been documented by gemological labs. Although their identification is straightforward, it is worth noting that some hybrid diamonds may go undetected by standard screening equipment if the underlying natural diamond is type Ia, as many screening instruments are based (either directly or indirectly) on differences between type Ia and type II diamond (figure 9). Kitawaki et al. (2023) produced hybrid diamonds by growing colorless CVD diamond on top of natural colorless type Ia diamonds. As expected, these hybrid diamonds passed standard screening tests using UV transparency, N3 defect detection, and bulk Fourier-transform infrared (FTIR) measurement. However, deep-UV imaging and PL spectroscopy identified them as natural diamonds with a CVD diamond layer. Growing colorless CVD diamond on natural type Ia diamond substrates requires precise control of the temperature around the natural diamond used as a substrate, and its application currently offers little economic advantage.

Color Changes in CVD-Grown Diamonds. Advances in laboratory growth techniques have enabled manufacturers to produce unique diamond products for which there is no known natural equivalent. In some photochromic diamonds, for example, defect concentrations and thus color can be temporarily modified by exposure to certain lighting conditions. CVD-grown diamonds that have been deliberately doped with high levels of silicon may show an interesting photochromic effect. The doping typically results in a prominent absorption peak at 737 nm caused by the SiV– defect. These diamonds may have a gray or pinkish brown to pink appearance when observed in ambient lighting conditions. With UV excitation, however, the concentration of the neutrally charged defect counterpart (SiV0, with absorption at 946 nm) increases due to charge transfer from SiV– centers, resulting in a more bluish color (figure 14; D’Haenens-Johansson et al., 2015b; Breeze et al., 2020). This color change is temporary, and the diamond will revert to its original stable color when exposed to white light.

Because the unstable blue color in CVD-grown diamonds can potentially revert to a stable pinkish brown or gray color, it is important to confirm the color stability of blue or gray CVD-grown diamonds by exposing them to white light for at least 30 minutes during testing. Such diamonds can also change color when heated (e.g., 550°C for 20 minutes in the dark; Breeze et al., 2020). Heating causes electron donors to convert SiV– into SiV2–, which does not absorb light (Breeze et al., 2020). The application of heat can cause the pinkish brown or gray diamond to appear colorless—this change is also temporary, and the diamond will revert to its stable color as it cools and is exposed to white light.

An additional form of reversible color change can be produced in CVD-grown diamonds, unrelated to silicon defects. Exposing some CVD-grown diamonds to UV radiation can cause the bodycolor to darken, while heating to temperatures above 450°C can decrease a stone’s color saturation (Khan et al., 2010). These color changes are only temporary and fully reversible, though the unstable color can be maintained if the stone is kept in the dark or inside opaque stone papers. Khan et al. (2009) attributed the color change in these diamonds to electron transfer from isolated nitrogen atoms to electron acceptor defects such as NVH0. NVH0 is a defect that exhibits IR absorption at 3123 cm–1 and can be detected in some as-grown CVD diamonds. Similar to the SiV– ↔ SiV0 color change, the original color can be fully restored using white light.

Although there have been some concerns in the trade (Bates, 2019), all photochromic and thermochromic color changes observed in laboratory-grown diamonds submitted to GIA have been temporary and fully reversible, without any permanent or long-term color changes. Furthermore, analysis of CVD-grown diamonds that were submitted multiple times showed no significant or systematic change in color grade, even with stones that were submitted to the GIA laboratory at intervals of several months to a few years.

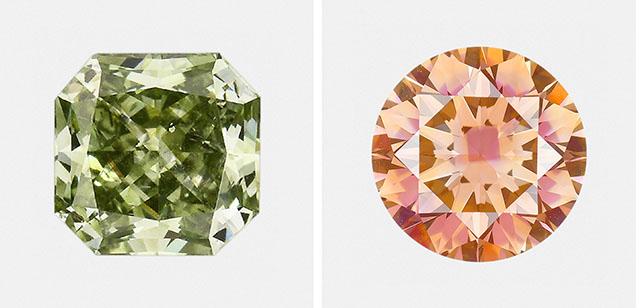

Unusual Fancy-Color Diamonds. Due to their vastly different growth conditions and chemistries, laboratory-grown diamonds can have unique colors. In HPHT-grown diamond, doping with high amounts of nickel produces an attractive green coloration that is quite distinct from the greenish appearance created by post-growth irradiation. By incorporating large amounts of nickel in the diamond lattice, an absorption band develops in the red portion of the visible spectrum, centered at about 685 nm, thus forming a transmission window in the green portion of the spectrum. To date, only a few HPHT-grown diamonds with saturated green coloration have been submitted to GIA (figure 15, left; Johnson and Myagkaya, 2017), along with a few dozen having Faint to Fancy Light green bodycolor due to high amounts of nickel defects (e.g., Eaton-Magaña, 2019). Some natural diamonds also have a greenish color caused by nickel impurities (Breeding et al., 2018), though generally at far lower concentrations than what is possible in laboratory-created versions, and they often have nitrogen-related defects that create a green-yellow color instead.

In HPHT-grown diamond, distinctive color zoning can occur as a result of growth sectoring (Howell et al., 2019). These growth sectors are detected in most HPHT-grown diamonds under deep-UV imaging due to the various concentrations of defects incorporated into each sector (Shigley et al., 2004). In some HPHT-grown diamonds, the defect concentrations are high enough and distinct enough between the growth sectors to create dramatic color zoning (e.g., figure 15, right; Eaton-Magaña and Linzmeyer, 2023). Another recent example is a 4.32 ct HPHT-grown diamond with pronounced blue and yellow color zones (due to boron and single nitrogen, respectively) that are visible face-up; these colors were intended to evoke the Ukrainian flag (Jeffay, 2023).

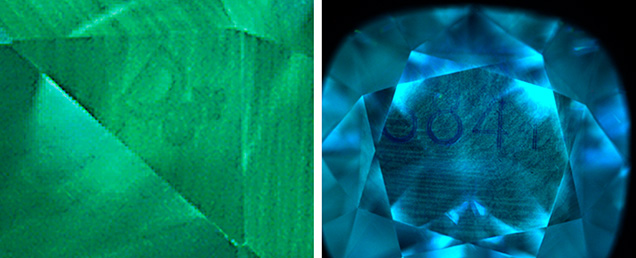

CVD-Grown Diamonds with Invisible Markings. A small subset of laboratory-grown diamond submissions have distinctive features that are only revealed using deep-UV excitation. Two CVD-grown diamonds—0.60 ct and 1.93 ct, both enhanced by HPHT treatment—had no identifying patterns when observed visually or with the microscope. When exposed to deep UV, however, logo marks and numbers appeared (figure 16; Odake and Kadam, 2023). These markings were not visible on the 1.93 ct sample when PL mapped with 455, 532, 633, or 830 nm laser. The different font styles and marking positions suggest that these two examples were produced by different methods. Although the method of creating these markings is unknown, they were likely intended as a tracking and security measure.

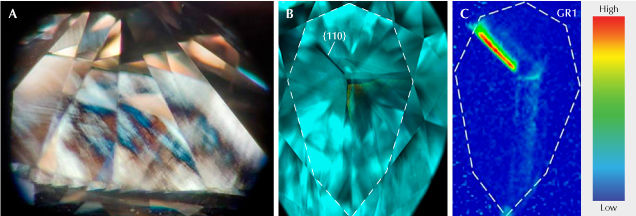

HPHT-Grown Diamonds with Strain. In general, colorless and near-colorless HPHT-grown diamonds have low impurity concentrations and uniform pressure is applied during growth, resulting in high crystalline perfection and very weak or almost no strain levels, except around inclusions and cracks (D’Haenens-Johansson et al., 2022). Though rare, HPHT-grown diamonds with strain have been previously reported (Ardon and Batin, 2016). Recently, the GIA laboratory received five stones showing two unusual features for HPHT-grown diamonds: a GR1 defect [V0] detected by PL spectroscopy, as well as the presence of strain (indicated by anomalous birefringence when examining the diamond through crossed polarizers; figure 17). GR1 defects are not usually detected in HPHT-grown colorless diamonds submitted to GIA laboratories. Analysis of the GR1 distribution using PL mapping in these strained HPHT-grown diamonds shows that the defect is limited to the {110} sector (figure 17C), consistent with previous reports (Loudin, 2017). Although this feature is currently rare, it is likely that these stones were distorted during synthesis, introducing the strain, and that GR1 was created by subsequent irradiation treatment.

CONCLUSIONS

With the advancement of CVD and HPHT growth processes, gem-quality laboratory-grown diamonds have become a significant part of the global gem trade. The rapid evolution of both HPHT and CVD diamond growth is driven by manufacturers’ efforts to develop innovative new products for both engineering applications and gem purposes. As manufacturers refine their growth methods, they can better tailor these products to satisfy consumer tastes and create niche products. In the coming years, we expect that most products will be in the colorless range and increasingly larger (e.g., figure 18). With the additional supply, we will likely see a greater variety of stones with a range of colors.

If the submissions to GIA are an accurate representation of the products on the market (excluding melee diamonds), then the data in this study indicates that the market for laboratory-grown diamonds has shifted dramatically toward colorless and near-colorless products (figures 2 and 3). There are a few exceptions, such as the fancy-color laboratory-grown diamonds treated by some producers (Bates, 2021).

Based on current trends, the quantity of HPHT-grown diamonds is expected to increase most significantly at the extreme ends of the weight scale: both small melee-sized stones and larger samples exceeding 4 ct. CVD-grown diamonds are being submitted at commercial sizes (i.e., non-melee) in far greater quantities than their HPHT-grown counterparts, and this trend is expected to continue.

Many manufacturers worldwide have committed significant capital investment toward their laboratory-grown diamond facilities (Lu et al., 2019; DeMarco, 2020) and developed marketing efforts promoting these stones as a readily available or environmentally friendly commodity (e.g., Lu et al., 2019; Bates, 2021). Although beyond the scope of this article, there are indications that in recent years laboratory-grown diamonds have begun to complement and, in some cases, replace sectors of the natural diamond market (Bates, 2023), especially as their prices have fallen. The long-term impact of laboratory-grown diamonds on the industry will continue to be assessed in the coming years.

This article has summarized many of the developments in laboratory-grown diamond production, based on submissions to GIA over the last two decades. Beyond providing a snapshot of the current range of products seen at GIA, this also allows us to project trends into the future as technological advances enable the controlled production of stones with specific sizes and colors. Even with the rapid progress of the past decade and ongoing developments, GIA’s advanced analytical techniques, backed by decades of research, can easily identify and characterize laboratory-grown diamonds.