A Large Aquamarine with Unusual Etch Features from Xinjiang, China

Etch features are commonly seen in beryl crystals (e.g., Spring 2002 GNI, pp. 102–103). Their formation is related to various factors during or after crystal growth, both internal and external, including chemical composition, lattice defect types and their distribution, pressure-temperature conditions of the forming environment, solvent composition, and dissolution time (R. Kurumathoor and G. Franz, “Etch pits on beryl as indicators of dissolution behaviour,” European Journal of Mineralogy, Vol. 30, No. 1, 2018, pp. 107–124).

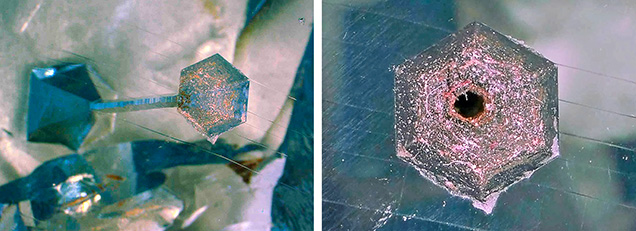

Recently, Shino Gold Jewelry (Shanghai) Co. submitted a large piece of rough aquamarine crystal to the National Gemstone Testing Center (NGTC) lab in Beijing for identification service. The crystal, weighing 778 g (figure 1, top), was claimed to have been mined in the Altay region of Xinjiang, China. Standard gemological testing revealed a refractive index of 1.577–1.583 and a specific gravity of 2.69. These values were typical for aquamarine and were confirmed by the infrared and Raman spectra. The numerous hexagonal etch features on the (0001) crystal face (figure 1, bottom), combined with the contents in the fissures (mainly kaolinite and hematite) identified by Raman spectroscopy, indicate that the crystal is of natural origin. Notably, one of the etch features has not been previously reported to our knowledge—the crystal had two hexagonal dissolution cavities with openings about 3 mm in diameter, connected by a hexagonal etch channel 4 cm long and parallel to the c-axis (figures 2 and 3). Interestingly, the etch channel appeared to be empty and penetrated throughout the crystal.

The formation of this etch feature cannot be fully explained at present. One possible explanation is that it is related to the defects (dislocations) parallel to the c-axis, which control the locations of the preferred dissolution process (T. Lu et al., “Observation of etch channels in several natural diamonds,” Diamond & Related Materials, Vol. 10, No. 1, 2001, pp. 68–75). Also, the formation of these special etch features is affected by different dissolution rates in different directions of the crystal. The selected dissolution on the (0001) plane was very slow, while the dissolution rate along the c-axis was significantly faster, resulting in the special funnel-shaped etch pits connected by a very long etch channel.