Observation of Etched Surface Micro-Features on HPHT Synthetic Diamonds Using Laser Confocal Microscopy

China is the world’s largest HPHT synthetic diamond producer, with an annual output of more than 3,000 tons of rough industrial diamonds. The production technology of HPHT synthetic diamond is quite mature, and most Chinese HPHT synthetic diamonds use the hexahedral static pressure method. The diamond crystals grow out of high-purity graphite through a high-temperature and high-pressure process, and then the superfluous graphite is removed by acid cleaning (Z. Song et al., “Identification characteristics of large near-colourless HPHT synthetic diamond from China,” Journal of Gems and Gemmology, Vol. 18, No. 3, 2016, pp. 1–8).

Acid cleaning of HPHT synthetic diamond is usually done with 90% H2SO4 and 10% HNO3. This process can remove graphite and metal impurities that remain on the diamond surface and in crevices (L. Yin et al., “Micromechanism of the artificial diamond’s growth,” Journal of Synthetic Crystals, Vol. 29, No. 4, 2000, pp. 386–387). During the growth process, the metal catalyst and graphite are in close contact with diamond and continuously participate in crystal growth.

To the best of our knowledge, no research has been done on the surface characteristics of HPHT synthetic diamonds after acid cleaning, which can reveal the growth features of HPHT diamond. In this study, 39 HPHT synthetic diamonds produced in China were observed using laser confocal microscopy (LCM). The laser confocal microscopy measures the surface topography of the sample moving focused laser spots over the sample with a galvanometer scanner. The strongest-intensity scanning points in each vertical scan layer are recorded and used to construct the 3D topography through a pixel-by-pixel method (W.-C. Liu et al., “A self-designed laser scanning differential confocal microscopy with a novel vertical scan algorithm for fast image scanning,” IFAC-PapersOnLine, 2017, Vol. 50, No. 1, 2017, pp. 3221–3226). Therefore, the laser confocal microscope can overcome the problem of depth of field and observe the surface characteristics of materials clearly.

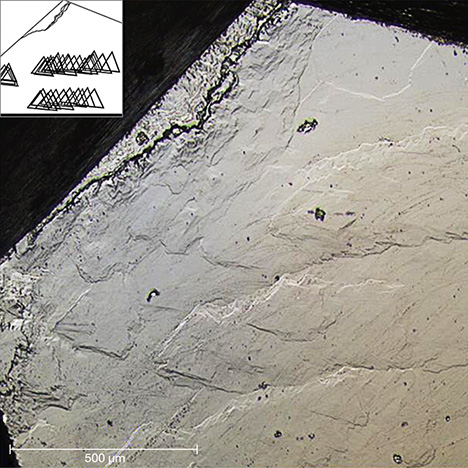

The characteristics of the structure after acid cleaning are observed on the surface of an HPHT synthetic diamond and on the inside of the crystal. An HPHT synthetic diamond was cut into thin slices and then washed by acid, exposing its internal structure (figure 1). Metal catalysts and a small amount of graphite remain in diamond crystals during growth, leaving holes in the interior. Due to the lack of raw material for growth in the hole, a step-like structure was left in the space that was not fully filled with crystallized diamond.

The fine structure of the step-like growth can be expressed by using the 3D scanning function of the laser confocal microscope. The images built in the three-dimensional coordinate system can show the depth and spatial relationship of the microstructures (figure 2). The irregularly etched structures, the depth of voids left by metal catalysts, range from 5 to 17 μm.

The inset shows a simulation of the sample’s stacked triangular growth structure. Photo

by Xuxu Wu.

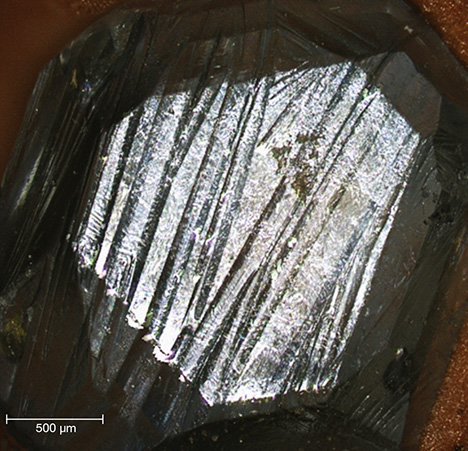

parallel lines. Photo by Xuxu Wu.

After acid cleaning, HPHT synthetic diamonds will display step-like irregular pits and lines on the surface (figure 3). The triangular growth structures of HPHT synthetic diamonds are stacked on the surface with slight displacement. Rectilinear line marks on the surface of HPHT synthetic diamonds (figure 4) are also very common, and may be traces of the displacements that develop between small crystals due to compression during the growth process.

Characteristic patterns observed on the surface of HPHT synthetic diamonds are related to metal catalysts and diamond particles, revealing the order of growth of synthetic diamonds. The step-like structure with the same angle is very common. The etched microstructure caused by metal catalysts usually displays irregular patterns. The several groups of parallel straight lines could be caused by the displacement and friction between a large number of tiny diamonds in the growth chamber. LCM is very reliable at revealing surface micro-features on HPHT synthetic diamonds, and it should be more widely applied to gemological research.

Contributors’ note: This study was partially supported by the National Natural Science Foundation of China (grants 41473030 and 41272086).