New Plastic Imitation Opal from Kyocera

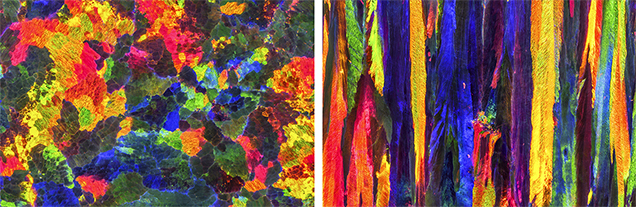

Recently, the Carlsbad laboratory examined an interesting new gem material manufactured by the Japanese company Kyocera that displayed a play-of-color phenomenon. In the trade, this material may be sold as an “opal-like product,” because of the play-of-color phenomenon observed (figure 1, left).

Standard gemological testing revealed a hydrostatic specific gravity (SG) of 1.35. The refractive index (RI) was measured as 1.49. According to GIA, an imitation is defined as a natural or manmade material that mimics the appearance of, and is used as a substitute for, another gem material. Likewise, a synthetic gem is defined by GIA as a laboratory-grown gem material with virtually the same chemical and physical properties as a natural gem. Because the gemological properties for this new material are out of range for natural opal (SG of 2.00 and RI between 1.37 and 1.47), it is best described as an imitation opal.

Visually, this new material is a very good imitation of natural opal. Gemologically, it is easy to separate from natural opal due to the comparatively high refractive index and low specific gravity. There are other possible decorative applications for this plastic opal imitation material due to the large sizes that can be produced. This attractive material is a welcome addition to the gem trade and is easy to separate from natural opal with standard gemological testing.