New Emerald Production from Belmont

The Belmont mine in Brazil has been a key emerald supplier in the global market for the past 40 years. It is one of the very few companies that can guarantee a complete mine-to-market chain of custody for the emeralds it produces. As open-pit mining became more expensive over the past decade, underground mining gradually generated a larger share of production at Belmont. Today, all mining activity at the original open pit is underground. Open-pit mining will continue in the two pits to the north of the original site. General manager Marcelo Ribeiro revealed some exciting news about the Canaan mine, about 2 km away from the original pit, and expansion plans for the sorting and cutting facilities.

Belmont acquired interest in the Canaan mine through a partnership with its original owners. Exploration and underground mining infrastructure are still ongoing at this site. Although the operation just started about a year ago, Ribeiro and his team have learned a lot about this deposit through field studies and chemical analysis. The interesting finding is that there is plenty of beryllium in this area, which makes the survey of chromium concentration critical to locating the mining targets. This is the exact opposite of the situation at the original Belmont site, where beryllium is the critical factor.

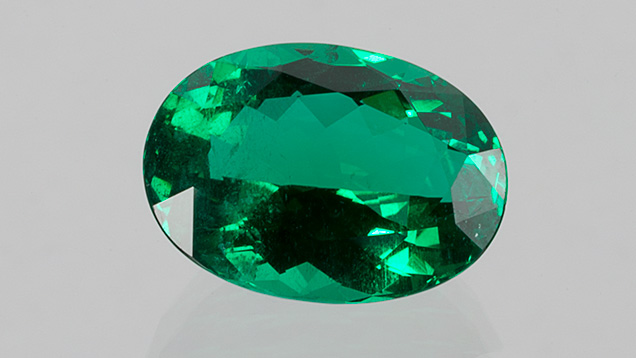

According to Ribeiro, two geological events were responsible for emerald crystallization in the area. The original Belmont mine is mainly influenced by the first event, Canaan by the second. Based on research, the second event was much stronger at the Canaan mine, destroying most of the crystals formed during the first event. The second-generation emeralds have a lower chromium concentration, and therefore lighter green colors, but they are often larger and cleaner than those from the Belmont mine (see above). The new production is sometimes slightly yellowish or bluish. Ribeiro is very excited about the Canaan production, which allows the company to provide a greater selection to its clientele.

Belmont currently cuts 50% of the Canaan production by value. All medium- to high-quality stones are cut on-site to add more value. To increase the capacity of the operation and make mining cheaper for long-term sustainability, the company plans to add two more optical sorters and further expand the cutting facility. Belmont will also keep promoting its mine-to-market product and better communicate with younger buyers to make them feel proud of their emerald purchases.