Mozambique: A Ruby Discovery for the 21st Century

INTRODUCTION

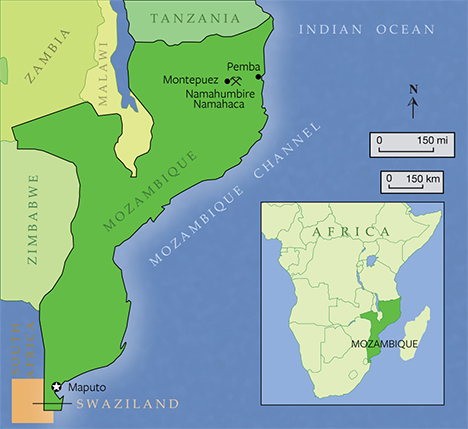

The Republic of Mozambique is located in southeastern Africa along the Indian Ocean. Separated from Madagascar by the Mozambique Channel, it is bordered by Tanzania to the north, South Africa to the south, and Zimbabwe, Malawi, and Zambia to the east (figure 1). The country boasts rich resources of natural gas, coal, titanium, and hydroelectric power. Agriculture is also important to the economy and includes extensive production of cotton, cashew nuts, sugarcane, tea, manioc root, tapioca, fruits, potatoes, beef, and poultry. Ruby mining is one of the newer economic sectors, with major developments in the northeastern part of the country in the mid to late 2000s.

The Montepuez ruby deposit was discovered in May 2009 (Pardieu et al., 2009). Shortly thereafter, thousands of miners, supported by foreign traders, began to illegally work the area. This continued until June 2011, with the formation of the Montepuez Ruby Mining company (MRM), a partnership between Mozambique’s own Mwiriti Ltd. and the multinational British gemstone mining company Gemfields. MRM acquired a 25-year concession in March 2012 and has expended considerable effort and capital to improve the mine’s infrastructure, machinery, staffing, security, and public relations.

While the public is generally unaware of Mozambique as a ruby source, the deposit near Montepuez is considered by the trade to be the world’s largest supplier. Gemfields’ first Mozambique ruby auction took place in Singapore in June 2014, marking a milestone for the global trade (figure 2). The US$33.5 million revenue generated by the auction put the spotlight on the MRM ruby deposit, as the entire inventory was the direct result of the ongoing bulk sampling at Montepuez. This bulk sampling will guide further development of large-scale mine operations.

The company employs about 400 people at the mine, plus another 300 contractors. Along with experienced personnel imported from other countries, the company also trains Mozambican locals, who make up the vast majority of the workforce, to attain high skill levels.

In September 2014, GIA researchers Tao Hsu, Vincent Pardieu, and Andrew Lucas visited the Montepuez ruby deposit (figure 3). Hosted by MRM, the expedition’s purpose was to witness the evolution and operation of this major deposit and to gather research samples for study by GIA’s laboratory.

AREA GEOLOGY

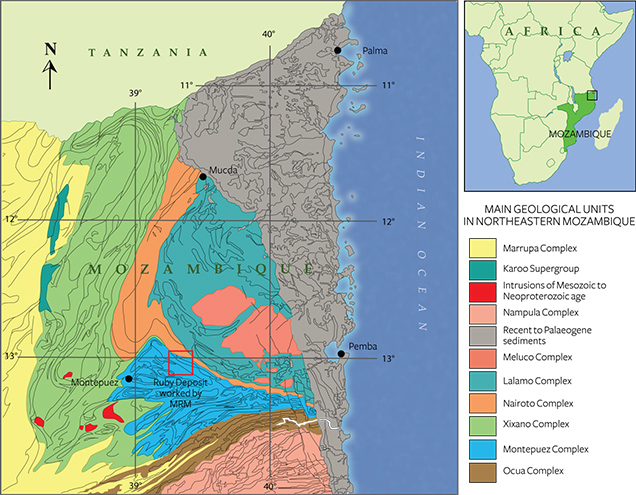

Northeastern Mozambique is located at a geologically critical junction between the north-south trending Mozambique Belt and the east-west trending Zambezi Belt (figure 4). Both are “treasure-bearing” Neoproterozoic (approximately 500–800 million years old) orogenic belts within the global Pan-African tectonic framework. Several major geologic complexes are separated by major thrusts and shear zones. Complex thermal and deformational events provided ideal temperature and pressure for the formation of ruby, garnet, and other minerals of economic importance.

The Montepuez ruby mine lies about 150 km west of the beautiful coastal city of Pemba (again, see figure 1). It is located within the wedge-shaped Montepuez Complex (Boyd et al., 2010). Its mineral assemblages indicate that the whole complex underwent amphibolite-grade metamorphism, generally at a pressure of 0.4–1.1 GPa and a temperature of 550–750°C.

Ruby forms only within a very limited range of pressure and temperature conditions, and only in the presence of a sufficient supply of aluminum, chromium, and oxygen. Around Montepuez, ruby formation seems to have resulted mainly from a metasomatic process, when fluid derived from the parental magma interacted with the host rocks in a low-silica environment.

The Montepuez operation consists of mostly secondary deposits, with only one primary deposit exposed so far. The composition of the rocks in the Montepuez complex ranges from granitic to amphibolitic, while quartzite and marble can be found inside and outside the concession property. The rocks are also strongly folded into tight isoclinal folds on all scales, later cut by a number of shear zones trending northeast to southwest.

The MRM concession is located on one limb of a fold with a subvertical axial plane striking east-west. At least four different deformation phases occurred in this area. The strong deformation history complicated the rock units on all scales, making the exploration and prediction of the primary ore very complex.

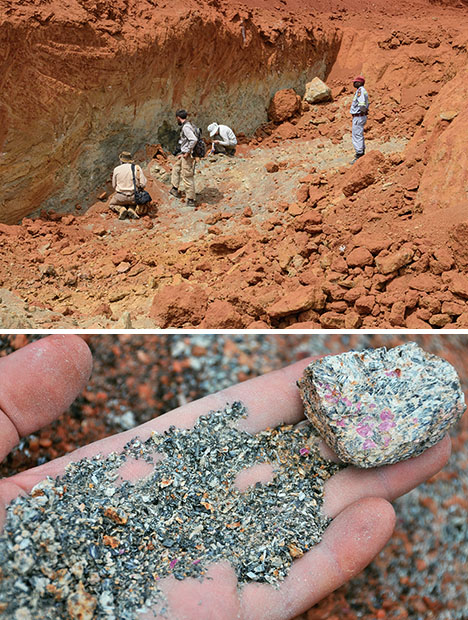

The pit walls in Maninge Nice, where the only primary deposit discovered so far is located, show an obvious contact zone between the topsoil and the weathered ruby-containing amphibolite, which is very fragile and easily crumbled by hand (figure 5). Ruby is found in close association with white feldspar, mica, and dark green amphibole. Core drilling data indicate that the amphibolite extends about 30 meters below the surface and lies on top of the basement gneiss. The whole amphibolite unit strikes roughly east-west.

Hundreds of millions of years of erosion have made the secondary ruby deposits in Montepuez far easier to uncover and work than the primary deposits. Rubies liberated from the host rock were transported and concentrated by water and eventually settled in the alluvial, colluvial, and eluvial deposits being worked today.

PALEOCHANNELS AND RUBY TRAPS

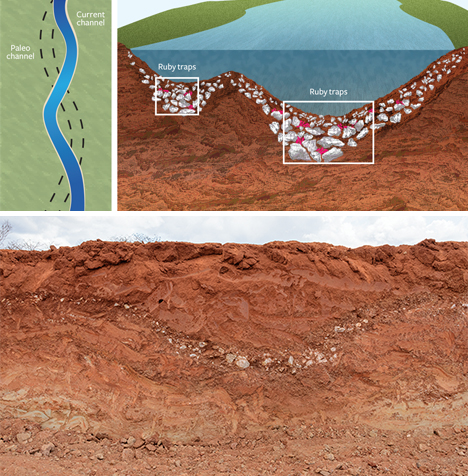

Cycles of weathering and erosion are constantly shaping the surface of the earth. Once the ruby-bearing rock is weakened and broken down by physical and chemical weathering, it is ready for erosion. In Montepuez, rubies and other minerals liberated from the parent rocks were picked up and carried by water and, due to their high specific gravity and hardness, trapped and concentrated in certain locations along current or former river beds, above the weathered basement rocks.

River channel morphology has also changed constantly over time. Hundreds of millions of years ago, the stream channels were at different positions; traces of their original flows are known by geologists as “paleochannels” (figure 6).

The concession has a well-developed drainage system. The local topography causes the water to flow generally from north to south. Present-day stream channels are quite recognizable and easy to work. MRM targets these as well as the richest paleochannels, where large reserves of fine rubies are buried.

Pit 3, the largest being worked by MRM, is located along one of the main paleochannels. On the wall of this pit, observers can see some superb cross-sections of former river channels (figure 6, right). Gravel size increases visibly from the edge to the bottom of these “traps,” where gravity caused heavier gravels to settle and concentrate at the bottom of a depression.

Larger gravels are better at slowing the water speed. Since the specific gravity of ruby is relatively high, it tends to settle along the bottom of a depression with other heavy minerals.

Heavy mineral traps occur at different places along the river channel, wherever the water current slows. The traps themselves work as natural jigs, usually leaving a higher concentration of ruby at the bottom of the trap. These ruby “traffic jams” are ideal locations for gem hunters.

Since there are numerous granitic rocks in the area, the gravels are mainly quartz crystals and aggregates of different sizes. Their shape and sharp corners indicate that they were not transported very far from their source rocks. The focus of secondary deposit exploration is to find old stream channels and better define the distribution of this ruby-bearing gravel layer.

THE MINE

The MRM concession encompasses roughly 400 square kilometers, with both primary and secondary deposits. Most of the bulk sampling takes place at the secondary deposits, but sampling is planned for both types within the current fiscal year. The only area with a primary deposit as well as secondary gravels is Maninge Nice, a local name given because of the “nice” stones that have come from there (figure 7).

Another major bulk sampling area is Mugloto. Pit 3 is in an area of Mugloto called Mashamba, a local name for the maize once farmed on the site (figure 8). Pit 5 is in an area called Mercado, which means “market” in Portuguese, as it was once an illegal miners’ market.

BULK SAMPLING METHODOLOGY

Secondary deposits host a concentration of fine stones. They are fairly easy to sample because most of the fractured and included stones were ground into sand by weathering. In the secondary deposits, everything above the gem-bearing gravel is overburden. MRM samples the gravel down to bedrock, often using two excavators—one to strip the overburden down to the gravel and the other to load the gravel into trucks that take it to the processing plant (figure 9).

The long-term bulk sampling strategy at the secondary pits is dictated mostly by the geology. MRM opened several bulk sampling locations based on exploratory auger drilling and on small 50 × 50 meter pits that all follow a single paleochannel. In one area, the company plans to merge several pits at some point, forming a massive operation along the paleochannel. The paleochannel in this area is approximately 4.5 kilometers in length, and the width of the pits varies from 50 to 150 meters. The large pit connecting them is about 2.5 kilometers long, and is expected to become longer. The end result will be a massive colored gemstone pit-mining operation.

MRM conservatively predicts the removal of 1.7 million tons of potentially gem-bearing gravel from the pit along this paleochannel. This will involve the handling of 15 million tons of rock. At the time of our visit, MRM was using four excavators, and another two were scheduled to arrive shortly. This will allow more pits to be sampled simultaneously, the doubling up of excavators in pits identified as crucial, and the starting of new pits.

As primary deposits go, the one at Maninge Nice is relatively easy to sample. The host rock is soft, weathered amphibolite, so removing it is not difficult or destructive to the crystals. This type of weathered rock offers a tremendous advantage in keeping costs down and production high. Still, future sampling at the MRM concession will likely involve the extraction of more primary rock at greater depths, increasing the challenge.

FURTHER EXPLORATION

The current bulk sampling and resource analysis stage is scheduled to be completed in 2016, which should give a clearer picture of the potential production figures and life of the mine.

Primary and secondary deposits require different drilling methods and strategies. The goal of secondary deposit exploration is to better define the distribution of the ruby-bearing gravel layer in the concession. Contours of the gravel layer will be constructed from this, as well as data on the concentration of rubies.

Auger drilling, a method not typically seen by GIA researchers, is used to explore the secondary deposits. The auger consists of a rotating helical screw driven into the ground. The screw blade is shaped to lift earth up from the borehole. As earth is pulled out of the hole, workers remove the loose gravel from between the drill blades (figure 10). This is different from core drilling, which removes solid or fragmented cores from hard rock. Auger drilling is considered an efficient way to explore soft unconsolidated material or weak weathered rocks.

Gemfields’ geologists have divided the target area into blocks and plan to drill boreholes in 100-meter grids. The drill bits and other equipment are hauled by truck to drilling sites. Every exploration team is composed of a geologist, a technician, and four or five workers. From setting up the machine to refilling the borehole, it takes about an hour to finish one spot. The goal is to finish eight to nine drill holes each day. The sites are cleaned and prepared before the drilling starts.

From ground level, the drill removes one meter of earth with every sampling until it hits the basement rock, where it will continue removing two to three meters of rock before it stops (figure 11). The average depth of the drill holes is about eight meters, and the team’s goal is to finish about 70–80 meters of drilling each day. MRM runs two shifts per day.

Drilling results will indicate the depth and thickness of the ruby-bearing gravel layer at each location. After thousands of drillings are done, a contour map will be constructed to show the depth and thickness of the area’s gravel bed. Prior to our visit, auger drilling had already helped delineate the aforementioned 2.5 km paleochannel, as well as many other sites with strong potential. Sampling the topsoil also gives the geologists a good idea how much waste they will need to remove before reaching the ore-containing gravel layer.

To obtain a representative sample, each meter of earth removed from the drill bit above the ruby-bearing gravel layer is thoroughly mixed, and then 50–100 grams of sample are taken for geochemical analysis to quantify certain elements. The results will guide further exploration and evaluation.

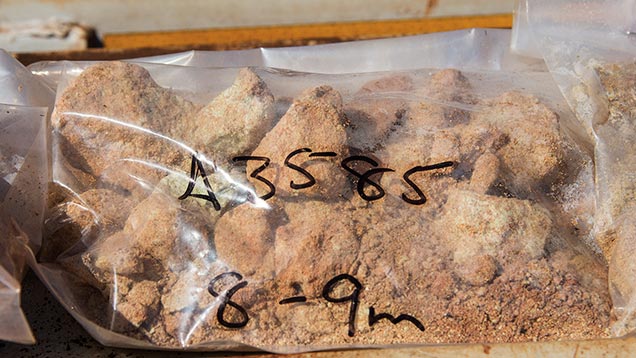

At the gravel layer, the drill removes 10–20 kilograms of ruby-bearing gravel, which is bagged and transported back to the washing plant and the sorting house for processing to get a rough estimate of ruby concentration (figure 12). The top one to two meters of basement rock are also washed to minimize the risk of losing rubies. The leftovers from all samples are carefully stored for future reference. The process is completed by refilling the drill hole in an environmentally responsible manner.

Ultimately, understanding the geology of the primary deposit is the key to sustaining a profitable mine. Geologists use geophysical tools to locate the host rock, targeting related amphibolite and magmatic intrusions.

Different mineral assemblages in rocks give off distinct magnetic signatures that can be displayed by a detailed magnetic scan. The results are used to model the distribution of certain rock types. Amphibolite usually gives a high magnetic anomaly that is easily distinguished from other rocks in the area. A high-resolution magnetic survey helps geologists form a map pinpointing the location of the amphibolite. Next, a radiometric survey on uranium, thorium, and potassium is performed to detect the alkaline magmatic intrusions in the area. Further exploration plans are based on these results.

The current exploration of the primary deposit involves extensive core drilling around the exposed Maninge Nice area (figure 13). The goal is to better define the distribution of ruby-bearing amphibolite below the surface. Each drilling extends about 50 meters deep and takes one week to finish, at an average rate of 10 meters per day. Drill bits coated with synthetic diamond are used to sample the rock at every meter. Drill sites are positioned every 100 meters unless more lithological variation is observed, in which case the distance is shortened to 50 meters.

Through extensive core drilling, the geologists have made some important underground discoveries. Each core starts with the loose topsoil, which is bagged. The ruby-bearing amphibolite is usually found at a depth of 10–30 meters, gradually becoming granitic gneiss, the basement rock in the area (figure 14). The exploration team drills down into the basement rock as well to see if the amphibolite repeats. Sometimes they discover a secondary ruby-bearing gravel bed above the primary deposit.

In addition to the amphibolite, which contains various concentrations of rubies, two marble bodies north of Maninge Nice have been defined. No rubies were found in the marbles, however. A detailed report on the primary deposit will be submitted to MRM in 2016.

PRODUCTION

As part of its bulk sampling operation, MRM has handled around 1.8 million tons of rock at Montepuez, recovering approximately 8 million carats of ruby and sapphire of various colors. The company hopes to double its capacity to 3.6 million tons of rock in 2015 and eventually increase that figure to 10 million tons of rock a year.

The actual recovery of ruby in the secondary deposits is more difficult to predict. The amount of ruby per ton can vary dramatically, and so can the quality of the rubies recovered. For example, the recovery rate in Mugloto pit 3 is relatively low: 0.60–1 gram per ton of ore processed. Yet the pit yields high-quality ruby, making it economically advantageous to sample, even with the low recovery rate. This pit also produces some large rough crystals of 6–8 grams. For comparison, Maninge Nice has a higher recovery rate of 20–35 grams per ton, but generally produces much lower-value material.

Overall, the recovery rate for the primary deposit is around 162 carats per ton, while the secondary deposits produce 31 carats per ton. The figure for the secondary deposits includes only processed gravels and not the amount of overburden topsoil moved.

WASHING AND SORTING

The Montepuez processing plant (figure 15) is organized into four major areas: (1) dry screening; (2) disintegration with a log washer, where the removal of waste particles begins; (3) wet screening; and (4) sizing and concentration. In an auxiliary section, water is held in a reservoir and cleaned for use in washing.

The washing process uses two screening systems and two jig systems, both of which separate the material by size (figure 16). The jigs have a batch system where any overflow from the first upper-level jig is retrieved by the lower-level jig. The 150 tons washed per hour deliver concentrated gravel containing various amounts of corundum rough.

Suction hoses pull the gravels from the jigs into canisters. Then the gravels are poured into bags and taken to the sorting house. The concentrated gem gravels are loaded into the back portion of a sorting box, a rectangular case with an angled glass window for viewing. This is the beginning of the process of separating ruby from the gravels and garnets.

To reduce the possibility of theft, the sorters never actually touch the rubies. They wear sleeves with rubber gloves attached (figure 17). They drop the retrieved stones into two holes, one for garnets and the other for corundum. The sorters base the identification on visual appearance, especially crystal morphology.

Next, a senior staff member and a member of the security team unlock the box holding the gemstones, and the corundum crystals are cleaned and sorted. The rough is divided into dark and light tones, representing ruby and pink sapphire, respectively. The rubies are then classified into four further categories: premium, facet-grade, translucent to opaque, and basic corundum.

The grading of the premium ruby rough is done in an adjacent room, first by color and then clarity. White tables provide the background, while windows just in front of the graders provide ample daylight for color grading. The Gemfields ruby grading system is based on the rough’s size, color, shape, and clarity (figure 18).

PRELIMINARY GEMOLOGY

Rubies from Montepuez are very important to the trade because of the large quantities and the wide range of qualities and sizes produced. Their colors bridge the gap between those from the classic sources of Burma (highly fluorescent, with low iron content) and Thailand/Cambodia (weakly fluorescent, with high iron content).

Rubies owe their red color to chromium, but their color is modified by the presence of iron, which reduces the chromium-caused fluorescence. An interesting aspect of rubies from the amphibole-related deposit near Montepuez is their iron content, which ranges from nearly as low as Burmese marble-type rubies to as high as rubies found in basalt-related deposits along the Thai-Cambodian border. This means they have the potential to suit a range of different markets.

A small but significant percentage of the material has a combination of color and clarity that requires no heat treatment. Others lack transparency due to fissures or the presence of inclusions. Heat treatment transforms this lower-quality material so it can find a market within the jewelry industry. Lead-glass filling is used for heavily fractured stones, while more traditional heat treatment (with or without borax-like additives) is performed on less-fractured stones with a milky or silk-like appearance (Pardieu et al., 2010). Overall, treated products are much more readily available than unheated material (Scarratt, 2012).

Each of Montepuez’s bulk sampling areas yields rubies with slightly different appearances. The material from Maninge Nice looks purplish red to red. Rough rubies from other areas tend to be darker and more brownish or orange. They generally have higher iron content—similar to Thai/Cambodia rubies—than the samples from Maninge Nice.

Rough rubies from Montepuez are mostly tabular. Specimens from the primary deposit are usually more euhedral, but also more fractured, and contain amphibole and mica inclusions (figure 19, left). Rough from the secondary deposit is generally more tumbled, more transparent, and less included (figure 19, right).

While there are some exceptionally large stones over 100 ct, most of the unheated faceted rubies from Montepuez are under 3 ct. Faceted stones over 10 ct were seen at the Bangkok and Hong Kong shows in September 2013. With their even coloration, high transparency, and good luster, unheated rubies from Montepuez are very suitable for calibrated cuts.

COLLECTING REFERENCE SAMPLES

GIA’s Bangkok lab has been collecting reference samples and mining information from sources since 2008. A study of the gemological characteristics of 131 ruby samples from Mozambique was completed by the laboratory and published by Pardieu et al. (2013). Studies of inclusions and chemical composition are in progress, and the results will be presented in future articles. The team’s current main focus is to collect and study ruby, sapphire, and emerald reference samples following GIA protocols.

At Maninge Nice, the team was allowed to search the ground under the supervision of company security guards (figure 20). The host amphibolite was highly weathered, making it very easy to extract the rubies from the host rock. Using rock hammers, the team collected a fair number of high-quality samples that met the requirements for lab preparation and analysis.

The specimens collected are especially valuable because they are “type A” samples. This means they were obtained directly from the rock by the gemologists themselves. Samples that are collected by the miners but not under the direct supervision of GIA researchers are classified as “type C” samples. These valuable reference samples will be important additions to the GIA reference sample database.