Letseng’s Unique Diamond Proposition

ABSTRACT

The Letšeng-la-Terae diamond mine in Lesotho, a small nation surrounded by South Africa, is unique in that it produces some of the world’s largest and highest-value diamonds from a relatively small volume of kimberlite ore. The mine, operated by De Beers during the late 1970s and early 1980s, was difficult to sustain economically because of its remoteness and very low ore grade, which made production costs very high. Since 2000, sharply rising prices for large diamonds have permitted the mine to reopen profitably as a 70/30 venture between Gem Diamonds Ltd. of South Africa and the government of Lesotho. To improve recovery of large diamonds, Letšeng’s owners have implemented new processing technology that provides better identification of these crystals before processing and a crushing mechanism that reduces their potential breakage. In recent years, several important diamonds recovered from Letšeng have been sold to London luxury jeweler Laurence Graff.

INTRODUCTION

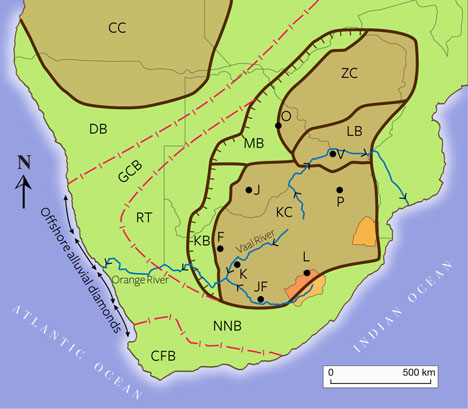

While the Premier (now Cullinan) mine in South Africa is usually cited as the traditional source for very rare large diamonds, in recent years the Letšeng-la-Terae mine in Lesotho has become the major producer of such stones (figure 1). Although its total output is relatively small—about 100,000 carats yearly, compared to two million or more carats from most major diamond mines—the average value of its production in 2014 was just above US$2,500 per carat (Gem Diamonds Ltd., 2014, 2015a). This is by far the world’s highest per-carat value, more than 21 times higher than the $116 average for diamonds mined worldwide, according to Kimberley Process data.

The Letšeng mine is also the world’s most consistent source of type IIa diamonds (those with exceptionally low nitrogen content), which account for about one-fourth of its production (Gem Diamonds Ltd., 2014). The mine claims six of the 20 largest diamonds ever discovered—478, 493, 527, 550, 601, and 603 ct (table 1). The largest of these, the Lesotho Promise, was found in 2006 and sold to London jeweler Laurence Graff for $12.4 million. In the years since, Graff has also purchased the 493 ct Letšeng Legacy, the 478 ct Light of Letšeng, and the 550 ct Letšeng Star.

| TABLE 1. Largest diamonds recovered from Letšeng. | |||||

| Name | Discovered | Size (ct) | Value | Sale price per carat |

|

| Unnamed | 1965 | 527 | no data | no data | |

| Lesotho Brown | May 1967 | 601 | US$302,400 | US$503 | |

| Lesotho Promise | Oct. 2006 | 603 | US$12.4 M | US$20,564 | |

| Letšeng Legacy | Sept. 2007 | 493 | US$10.4 M | US$21,095 | |

| Light of Letšeng | Sept. 2008 | 478 | US$18.4 M | US$38,493 | |

| Letšeng Star | Aug. 2011 | 550 | US$16.5 M | US$30,000 | |

Until 2004, Letšeng had been shut down for more than 20 years because its low grade and remote location made mining unprofitable at existing diamond prices. Up until the past decade, De Beers and other mining companies typically sacrificed large crystals for the sake of rapid throughput, which maximized efficiency and reduced mining costs. Only after prices for large stones began rising sharply did the mining economics change in favor of preserving them. Because the economic viability of Letšeng hinges on its ability to produce very large diamonds, the owners have employed new recovery processes to reduce damage and breakage of such diamonds. The mine is a major force of Lesotho’s economy, employing about 1,500 workers, 90% of them locals. Letšeng accounts for 70% of the country’s corporate tax revenue and 60% of its foreign exchange earnings (M. Maharasoa, pers. comm., 2014).

BACKGROUND

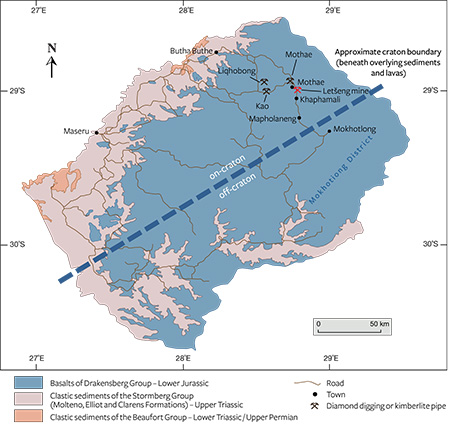

The Kingdom of Lesotho is a nation of rugged mountains (figure 2) set within the boundaries of South Africa (figure 3). Its capital, Maseru, is located about 250 miles south of Johannesburg. When diamonds were discovered in South Africa in 1867, Lesotho (then known as Basutoland) was sparsely settled by agrarian villagers and shepherds living under the rule of King Moshoeshoe.

The tiny kingdom struggled to remain independent from its much larger neighbor, first resisting Zulu invasions from the south and then becoming embroiled in the growing tensions between the British and Afrikaners in southern Africa during the 1870s. The Afrikaners (descendants of early Dutch settlers) had begun to claim parts of the territory. While Basutoland’s craggy mountains made for good defense, with more than 80% of the nation at least 5,000 feet above sea level, the British annexed the region in 1871. The rugged terrain also hindered exploration for minerals, including diamonds. Large-scale agriculture was nearly impossible, which made it unattractive for colonial settlers. As a result, Basutoland remained fairly isolated from the wars and mineral rushes that shaped the southern portion of the continent during the 20th century (“Lesotho,” 2014).

By road, Letšeng is located approximately 214 km (133 miles) northeast of Maseru. The route is paved except for the last 30 km, which is a well-graded gravel road with many sharp hairpin turns. The mine’s complete name is Letšeng-la-Terae (also spelled Terai), which means “the swamp at the turn,” as it is located in a low saddle in the mountain range where the road makes an abrupt turn (Whitelock, 1979). The diamondiferous deposit was found in kimberlite under the superficial swamp sediment layer.

GEOLOGICAL FRAMEWORK

Figure 4 shows that the western lowlands and parts of southern Lesotho consist of horizontally bedded sediments, whereas a thick series of flat-lying basaltic lavas form the mountains in the east. The sediments belong to the upper part of the Karoo Supergroup (late Carboniferous to mid-Jurassic, 330–180 Ma), which once covered a major portion of southern Africa. In Lesotho, these sediments form part of the Stormberg series, which are Triassic (roughly 250–200 Ma) in age and consist of pale multicolored sandstones with intercalated grits, mudstones of the Molteno (fluvial sands), Elliot (red, green, and purple mudstones, previously called Red Beds), and Clarens (cream-colored aeolian sands, previously called Cave Sandstone) formations. These are overlain by the Early Jurassic (183 Ma) Drakensberg Beds, a monotonous series of flood basalt lava flows. The base of the lavas lies at an elevation of 1,600 meters, while the top is above 3,200 meters, for a stratigraphic thickness of more than 1,600 meters. Fine-grained basaltic dikes and sills contemporaneous with the lavas occur in the lowlands and mountains in a wide zone trending ESE-WNW. Hundreds of kimberlite pipes and dikes intruded in the Middle to Late Cretaceous (120–65 Ma) in many parts of southern Africa, and in Lesotho in the 95–85 Ma interval (Wilson et al., 2007). They occur mainly in northern and northeastern Lesotho (again, see figure 4), occupying the same ESE-WNW zone as the fine-grained basaltic dikes. Known at present are 39 pipes and 23 dike enlargements, usually called blows. Of these 62 bodies, 24 are diamondiferous. Moreover, there are more than 300 individual dikes. The age of intrusion of the Letšeng pipes has not been measured directly but is assumed to be similar to neighboring pipes. For instance, zircon from Mothae is 87 Ma (Davis, 1977), while ages of perovskite from Kao, Liqhobong, and Mothae range from 89 to 95 Ma (Lock and Dawson, 2013).

According to Clifford’s Rule (as refined by Janse, 1994), the occurrence of economic diamondiferous kimberlites is restricted to the Archean (2,500 Ma) interior of the seismically stable, erosionally flattened area of continental crust plus mantle known as a craton (see Shirey and Shigley, 2013), which is composed of a basement older than 1,800 Ma. Janse (1994) refined Clifford’s Rule in stating that economic kimberlites occur only on archons (the Archean part of a craton) older than 2,500 Ma. As previously noted, in Lesotho this cratonic basement is hidden by overlying Triassic to Early Jurassic sediments and lavas (again, see figure 4). Archean basement must be present at depth because pieces of Archean-age mantle and crust occur in the Letšeng kimberlite pipes, showing that they fall within the window of potentially economic diamond deposits. Letšeng lies close to the eastern edge of the Kaapvaal craton, where remnants of the original Stromberg sediments and volcanics remain and the upper portions of the pipes are still preserved.

GEOLOGY AND PETROGRAPHY OF THE LETŠENG PIPES

The high proportion of very large and type IIa diamonds in the Letšeng kimberlite has puzzled geologists. Letšeng sits near the edge of the Archean craton (see box A). In the Archean, this location might have permitted distinctive low-nitrogen, diamond-forming fluids access to the deep lithospheric mantle where the Letšeng diamonds were grown. It is possible that these diamonds did not grow in one short geologic event but slowly, over a longer geologic interval. If so, the high proportion of large diamonds could relate to especially slow growth rates from these fluids. But confirmation of these ideas would depend on detailed mineralogical studies of growth zonation and accurate age information, in particular for absolute age and/or core-to-rim ages that would reflect the duration of diamond growth. Such studies do not exist at present because of the high value of these stones—they cannot be sacrificed for research—and the exceptionally low abundance of mineral inclusions.

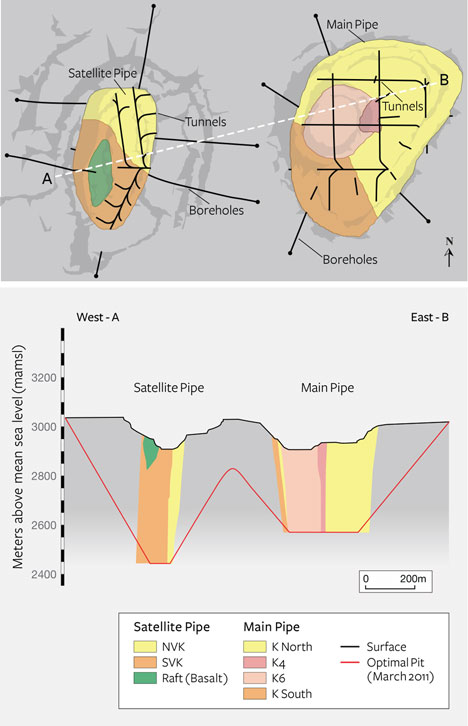

The Letšeng kimberlites consist of two pipes, the Main and the Satellite (figure 5), measuring 17.2 hectares (540 × 365 m) and 5.2 hectares (425 × 130 m), respectively. The pipes are carrot-shaped bodies, vertically intrusive and slightly tapering with vertical to slightly inclined walls, 83° at most. They are elongated in a northerly direction, roughly perpendicular to the general westerly trend of the fine-grained basaltic dikes, which suggests that the pipe locations were influenced by crosscutting structures. The contact between the kimberlite and the lava flows of the country rock are sharp, giving no indication of upfolding or chemical alteration. In places there is a 1 to 1.3 m marginal zone within the pipe where the kimberlite is sheared, with mud seams and calcite veins. The Letšeng kimberlites belong to the group 1 class of kimberlites, the generally non-micaceous type. Their texture is volcaniclastic.

The simple structural division into crater, diatreme, and root zones has been modified during the last decade (Scott Smith et al., 2008). Based on microscopic observation of core samples, petrographers now recognize volcaniclastic and hypabyssal kimberlite rocks instead (figure 6, top). Volcaniclastic kimberlite occurring in the crater, and layered in successive pulses, may be resedimented due to slumping. This resedimented volcaniclastic kimberlite becomes more massive, nonlayered kimberlite in the pipe and is often referred to as tuffisitic kimberlite breccia. This is the general kimberlite breccia present in many specimen collections. Hypabyssal kimberlite is a dense aphanitic (evenly fine-grained, non-breccia) rock occurring in the root zone. The degree of erosion in the general countryside can expose these rocks at different levels in the vertical zoning (Scott Smith et al., 2008). The Letšeng kimberlites contain easily visible centimeter-sized olivine crystals set in a groundmass of olivine (mainly altered to serpentine), phlogopite, and calcite. Crystals of purplish to dark red pyrope, black ilmenite, and green chrome diopside can occasionally be seen in the rock or among the minerals in the surface rubble.

The Letšeng kimberlite is covered by one meter of spongy soil (primarily on the Main pipe), two meters of leached white gravel, five meters of brown basaltic gravel (mainly on the Satellite pipe), one meter of yellow ground (oxidized kimberlite), and 20 meters of soft kimberlite “blue ground” and “yellow ground”. Below this depth, the kimberlite becomes hard bluish grayish greenish rock descending at least 700 meters (see pipe cross-section in figure 6).

During public digging access from 1959 to 1967 (figure 7), artisanal miners occasionally recovered very large crystals from the gravels on top of the pipes and in the gravels of nearby streams that drain the Main and the Satellite pipes. Formal mining by De Beers (1977–1982), Letšeng Diamonds (Pty) Ltd. (2004–2006), and Gem Diamonds Ltd. (2007 to the present) has removed most of these near-surface deposits. Mining currently takes place in the hard kimberlite, which requires blasting and crushing.

Similar to kimberlites elsewhere, the pipes contain several pulses of kimberlite magma that are slightly different in age and, more importantly, in the size, content, and quality of the diamonds. It is therefore necessary to outline their horizontal and vertical dimensions to recover diamonds of the highest grade. Four varieties of kimberlite are recognized in the Main pipe: K North, K South, K6, and K4 (again, see figure 6, top). K6 is economically the most important, as it contains the highest diamond content. It forms a separate sharply demarcated explosive volcanic breccia pipe known as a diatreme in the western part of the kimberlite, measuring four hectares (245 ×185 m). This is the area previously mined by De Beers and now by Gem Diamonds. K6 is a soft, friable, greenish gray rock with visible crystals of olivine and occasionally orthopyroxene, set in a fine groundmass. Xenoliths of basaltic lava are abundant throughout and accompanied by a wide variety of basement rocks (gneisses and amphibolites) and ultramafic nodular fragments that include garnet lherzolites (Lock and Dawson, 2013). Garnet xenocrysts are also relatively abundant (Bloomer and Nixon, 1973). In the Satellite pipe two varieties are recognized: NVK and SVK (north and south volcaniclastic kimberlite), while a raft of basaltic rock occupies the upper part of the pipe (again, see figure 6).

The Main pipe accounts for 75% of the mine’s output and has an average grade of 0.88 carats per hundred metric tons of material, while the Satellite pipe has a yield of 2.6 carats per hundred metric tons (Gem Diamonds Ltd., 2013). Their average is by far the lowest for any diamond mine in the world, which range from 5 to 400 carats per hundred metric tons but typically from 50 to 100 carats per hundred metric tons. By comparison, De Beers’s Venetia mine, located 500 miles to the north, yields about 110 carats per hundred metric tons (Krawitz, 2014).

EXPLORATION

Stockley (1947) reported kimberlites in the Maloti Mountains of Basutoland as early as 1947, though no diamonds were found at the time (Nixon, 1973). Several additional kimberlites reported by Col. Jack Scott in 1955 added to the notion there might be diamonds, though none were discovered. Scott later got De Beers to assist him in further prospecting operations. But it was Peter H. Nixon, as a Harry Oppenheimer PhD scholar from the Research Institute of African Geology at the University of Leeds, who discovered in 1957 the two diamondiferous kimberlite pipes at Letšeng-la-Terae (Nixon, 1960). He noted that Lesotho’s many kimberlite pipes are mostly barren of diamonds. Occasional reports of large diamond finds began to circulate nonetheless. Lesotho Kimberlites (1973), a book Nixon later compiled and edited as chief geologist in the country’s Department of Mines and Geology, noted that some 1,200 diggers were working the area by 1965, a number that quickly swelled to some 6,000 within two years.

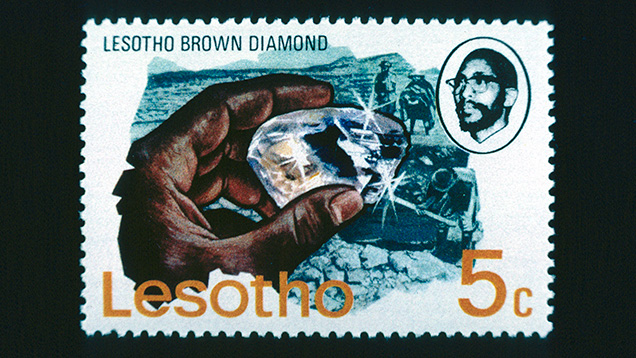

The eureka moment for Lesotho came in 1967, when a digger, Ernestine Ramaboa, unearthed a brown colored diamond weighing 601.26 ct in the area of Letšeng-la-Terae. Ramaboa and her husband, Petrus, reportedly secreted the diamond away, feigning illness to avoid arousing the suspicions of fellow diggers, and then walked for four days across the mountains to the capital city of Maseru to sell their find (figure 8). News of the find spread quickly, and it was reported that the government had to step in to guarantee the Ramaboas’ safety (Balfour, 1981).

![Ernestine and Petrus Ramaboa with Lesotho Brown diamond] Ernestine and Petrus Ramaboa with Lesotho Brown diamond]](https://www.gia.edu/images/F15-Shor-fig8--(SEEKING-USAGE-RIGHTS)_190903-468x468.jpg)

At the time it was reported to be the world’s eleventh-largest gem-quality diamond—and the largest reported found by an artisanal miner (Sotheby’s, 2008). The diamond was named the Lesotho Brown (figure 9). The government set up a sealed tender to obtain the best possible price for the diamond. According to the September 1967 issue of Diamond News and S.A. Jeweller, this colossal gem was first sold for 216,300 rand (equivalent to $302,400 at the time) to South African dealer Eugene Serafini. In 1968 it was purchased, also via auction, by American jeweler Harry Winston. A fitting epilogue to the story is that Winston invited the Ramaboas to New York City for the unveiling and cleaving of the diamond. The moment was broadcast on live television across the United States (Balfour, 1981). The Lesotho Brown rough yielded 18 diamonds, including the Lesotho I, a flawless 71.73 ct diamond, and the Lesotho III (figure 10), a 40.42 ct marquise purchased by Aristotle Onassis and given to Jacqueline Kennedy as an engagement ring. In 1996 the Lesotho III ring sold at an auction of the former First Lady’s estate for $2,587,500 (“Jackie O Lesotho diamond sells…”, 1996).

GOVERNMENT DIGGINGS

Ramaboa’s discovery brought a wave of local small-scale miners to the Letšeng-la-Terae area. Despite their rudimentary tools and mining methods, they found a number of diamonds (Maleleka, 2007). In an effort to gain control over Letšeng-la-Terae, the government, through the Lesotho National Development Corporation, granted Rio Tinto Zinc (RTZ, now Rio Tinto) an exploration license in 1968. RTZ upgraded the road and airstrip in the remote area and built a sampling plant. Beginning in 1969, RTZ sampled the Main pipe to about 55 meters deep, recovering 2,635 carats over the duration of the project. The company’s final report, issued in 1972, confirmed what many people suspected: that the grade was very low, though it occasionally produced unusually large diamonds. In the sampling carried out by RTZ, for example, over 90% of the value came from less than 10% of the diamonds—six stones, in fact—one of them nearly 50 ct (Chadwick, 1981). There was also the remoteness and inaccessibility of the area, which at the time made development costs uneconomically high. After RTZ declined to mine the deposit, the government granted licenses to individual diggers using limited mechanization who worked three-square-meter claims. For their part, the locals continued to find diamonds (Maleleka, 2007).

After RTZ’s departure, the government of Lesotho asked De Beers in February 1975 to reevaluate the data collected by Rio Tinto. In a move that surprised some analysts, De Beers chairman Harry Oppenheimer signed an agreement with the prime minister in December 1975 to develop the mine. “De Beers will go ahead with the mine in spite of the risk—an obvious risk judged by Rio Tinto’s findings against such a venture,” according to one newspaper story (Payne, 1975). Even De Beers harbored some misgivings. As Oppenheimer noted, “We are certainly doing something that is pretty risky which I don’t think other people would be inclined to do, and while I think that this is some way of philanthropy, we certainly were influenced by our desire to play a part in the development of Lesotho” (“Latest reports from the Lesotho Dept. of Mines,” 1978; Madowe, 2013). The agreement factored in a 25% government share and a seat for the government on the board of directors of a Lesotho-based joint venture formed by De Beers. Between 600 and 900 people, mostly Basotho, were to be employed.

Diamonds would be sold through De Beers’s marketing arm, then called the Central Selling Organization (CSO). The amount owed to the state from tax and dividends, once the capital had been amortized, was nearly 65% of sales. The mine’s profitability was an open question, given the amount of investment needed for its infrastructure (“Onstream, upstream,” 1977). Announcing the decision, a De Beers press release detailed the challenges:

Furthermore, a road costing three million rand ($3.7 million at the time) would be built through the mountains, connecting the mine to both Johannesburg, South Africa and the country capital, Maseru. The mine officially opened in November 1977. At a cost of more than 30 million rand (US$37 million), it went at least 6 million rand ($7.4 million) over its intended budget. De Beers geared the plant to do the primary sorting and washing to identify larger gems before the ore went to the crusher. The company also installed an X-ray machine to further identify larger diamonds after the initial crushing to retrieve them before secondary crushing (Chadwick, 1981).

In 1978, a 130 ct colorless diamond was recovered, which mine manager Keith Whitelock noted would help defray operating costs for a year. Diamond prices peaked in 1980, with the high-quality stones leading the way. But prices fell sharply the following year and continued sliding. In 1982, De Beers decided to close operations (figure 11) because the cost of running Letšeng had become untenable (Blauer, 2010).

For its five years of operation, De Beers’s production totaled 272,840 carats recovered from processing 9.4 million tons of kimberlite at the Main pipe, for a grade of 3.03 carats per hundred metric tons (table 2). About 65% of the output was gem quality, while 27% was industrial and 8% was bort (suited for crushing into abrasives). Only 7.6% of the production was larger than 14.7 ct, yet these accounted for 62% of the mine’s revenue (Venter, 2003).

| TABLE 2. Diamond production of Letšeng, 1955–2014. | |||||

| Period | Carats | Ore (metric tons) | Value/ct (US$) | Grade (cpht) | Operator |

| 1955–1968 | 62,070 | nd | nd | nd | artisanal |

| 1969–1972 | 2,000 | 80,000 | nd | 2.5 | RTZ |

| 1972–1976 | 43,000 | nd | nd | nd | artisanal |

| 1977–1982 | 272,840 | nd | nd | 3.03 | De Beers |

| 1983–2003 | 117,000 | nd | nd | nd | artisanal |

| 2004 | 14,000 | nd | nd | nd | Letšeng-JCI |

| 2005 | 37,000 | nd | nd | nd | Letšeng-JCI |

| 2006 | 54,677 | 2.6 M | 1,100 | 2.11 | Letšeng-JCI |

| 2007 | 73,916 | 4.0 M | 1,976 | 1.85 | Letšeng–Gem Diamonds |

| 2008 | 101,125 | 6.6 M | 2,123 | 1.53 | Letšeng–Gem Diamonds |

| 2009 | 90,878 | 7.5 M | 1,534 | 1.21 | Letšeng–Gem Diamonds |

| 2010 | 90,933 | 7.6 M | 2,149 | 2.00 | Letšeng–Gem Diamonds |

| 2011 | 112,367 | 6.8 M | 2,776 | 1.65 | Letšeng–Gem Diamonds |

| 2012 | 114,350 | 6.6 M | 1,932 | 1.75 | Letšeng–Gem Diamonds |

| 2013 | 95,053 | 6.5 M | 2,050 | 1.46 | Letšeng–Gem Diamonds |

| 2014 | 108,596 | 6.4 M | 2,540 | 1.70 | Letšeng–Gem Diamonds |

|

Value in US$ per carat; cpht = carats per 100 metric tons; nd = no data

Sources: Bowen et al. (2009) and Gem Diamonds annual reports for 2007 to 2014 |

|||||

SECOND LIFE FOR LETŠENG

After De Beers’s departure, the mine was worked sporadically by artisanal diggers from 1983 to 2003, but no formal mining was done. A second life for Letšeng began in 1999 when the Lesotho government, coming off several years of political instability and violent demonstrations in Maseru, sought help to redevelop the resource to provide sorely needed national revenue (Shor and Weldon, 2014). The result was a consortium, Letšeng Holdings SA, comprised of Matodzi Resources, Johannesburg Consolidated Investments (JCI), and Letšeng Guernsey, that took a 76% share in the venture, with the government holding the remainder. JCI, a South African gold mining firm, provided the start-up funding of approximately US$20 million (Venter, 2003). After extensive negotiations, the government and consortium agreed to a 7% royalty on diamonds sold, coupled with a 35% corporate income tax—much lower than the 15% royalty and 50% corporate tax levied on De Beers (Venter, 2003). By the time the mine was ready to begin producing, JCI had acquired a 50% share of the Letšeng Holdings consortium and commissioned a second processing plant designed to double its capacity. Mining began in May 2004, starting with the ore that De Beers had left stockpiled. The company anticipated an annual output of 68,000 carats beginning the following year (Hill, 2006; Telfer and McKenna, 2011).

Expansion began in earnest in 2005, when Letšeng Holdings held an initial public offering (IPO) with the goal of raising $31.4 million to build the new processing plant (figure 12). The sale was buoyed by the discovery of a 186 ct diamond, quickly followed by a 72 ct stone (Zhuwakinyu, 2005).

Despite the IPO, the company fell short of the additional $26 million needed to develop the mine to full operation. As a result, JCI began negotiations to sell the Letšeng Holdings stake to Gem Diamonds, a deal that was finally signed in the fall of 2006 for $130.1 million. It resulted in a restructured ownership with a new name, Letšeng Diamonds Ltd. The government took a 6% larger stake, now totaling 30%, in exchange for a $5.54 million loan that would be repaid to the new company (Hill, 2006). Gem Diamonds owns the remaining 70% interest.

Restarting production remained a challenge because of the difficulties noted above and because the depth of the deposit was never fully sampled by Rio Tinto or De Beers (R. Burrell, pers. comm., 2014).

MINING AND PROCESSING

When Gem Diamonds acquired the right to mine the concession in 2006, Letšeng had resumed active mining for just over a year, with an annual production of 55,000 carats. To lower costs and increase efficiency, Gem Diamonds turned to a relatively new mining method, designed for twin pipes, called split-shell open-pit mining. Traditional open-pit diamond mining involves gradual hollowing out of the entire kimberlite pipe in circular stages and, as the pit grows deeper, cutting away walls in progressively wider concentric circles. With each circle, the cut (or “waste stripping”) becomes wider, so deeper mines incur increasingly higher costs as the percentage of waste to kimberlite rises. In addition, waste disposal becomes much more costly.

With the split-shell concept, the waste stripping and mining is done on one side of each pit in alternate cycles—one cycle on the northern side of each pit, then switching to the southern side. The waste is removed via a common ramp between the two pipes. The split-shell method can target higher-grade areas of each pipe and defer a large amount of waste stripping, because only part of the kimberlite is being mined at any one time. As a result, mining companies can recoup their costs much faster. A study conducted at De Beers’s Venetia mine in South Africa, which converted to the split-shell method after seven years of traditional mining, found it reduced costs by 25%. Earthmoving equipment requirements were reduced by 30%, and yearly waste removal went from 32 million to 20 million metric tons, while maintaining the same level of diamond production (Gallagher and Kear, 2001).

There are risks, however. First, concentrating mining operations in the highest-grade sections of the deposit for too long can shorten the mine’s life by rendering the lowest-grade areas of the pipe uneconomic. Mining operations must be carefully balanced between the sections of the pipe to ensure this does not happen. In addition, the costs will eventually rise after it becomes necessary to remove the waste from the sections of the pipe that have been deferred (Gallagher and Kear, 2001).

At Letšeng, De Beers mined a small section called K6, the highest-grade portion of the Main pipe down to 120 meters, and began working the “softer ore” section of the Satellite pipe (Telfer and McKenna, 2011). Today, most of the mining is done in the area adjacent to the section De Beers worked (K4). The Main and Satellite pipes are being worked at about 150 meters, with indicated resources (sampled with reasonable knowledge of the grade) down to 210 meters. Gem Diamonds engineers note that the mine’s previous operators did not adequately sample deeper areas of the pipe. The company has recently sampled down to a depth of 476 meters at the Main pipe, still finding diamonds but uncertain of the grade. This is an inferred resource. The Satellite pipe has an inferred resource down to 628 meters. The company has test-bored as deep as 800 meters and is still evaluating the samples (R. Burrell, pers. comm., 2014).

A 2011 report noted that indicated resources as of December 31, 2010, were calculated at about 77 Mt (million metric tons), at a grade of 1.61 carats per hundred metric tons (cpht), yielding 1,238,000 carats worth $2,629 per carat at 2011 market prices, or roughly $33 billion. Inferred resources added another 141 Mt at a grade of 1.72 cpht, yielding 2,423,200 carats worth $2,733 per carat, or $67 billion (Telfer and McKenna, 2011). This equates to a 30-year mine life. A more immediate probable mining reserve is calculated at 76.4 Mt at a grade of 1.60 cpht, yielding 1,221,700 carats worth $2,631 per carat in 2011 (see also tables 3 and 4).

| TABLE 3. Probable mining reserves as of December 31, 2010. | |||||

| Occurrence | Tonnage |

Grade

(cpht)a

|

Carats |

Value

per carat

|

|

| Satellite pipe | 17.02 M | 2.07 | 353,000 | US$3,170 | |

| Main pipe | 59.22 M | 1.46 | 867,000 | US$2,414 | |

| Stockpile | 0.17 M | 0.87 | 1,500 | US$1,209 | |

| Total | 76.41 M | 1.60 | 1,221,700 | US$2,631 | |

|

acpht = carats per 100 metric tons

|

|||||

| TABLE 4. Probable, indicated, and inferred reserves of Letšeng, as of December 31, 2014. | |||||

| Probable | Indicated | Inferred | Total | ||

| Ore (million tons) | 131.9 | 187.1 | 106.8 | 293.9 | |

| Grade (ct/100 tons) | 1.71 | 1.73 | 1.67 | 1.71 | |

| Carats (million) | 2.26 | 3.23 | 1.78 | 5.01 | |

| Value per carat | US$2,045 | US$2,036 | US$2,051 | US$2,073 | |

|

Source: Gem Diamonds Ltd. (2015a)

|

|||||

Letšeng is also unusual in that it yields only a small percentage of diamonds less than two millimeters. Because of this, the recovery operations do not screen for diamonds below that size (Bowen et al., 2009).

From these figures, the value of one ton of ore can be calculated as roughly $42, which is in line with other economic kimberlite mines in southern Africa. Previous and current mining has shown that the Satellite pipe has a slightly higher grade and a slightly higher content of large diamonds than the Main pipe (Telfer and McKenna, 2011).

Complicating the mining of the Satellite pit is that during the kimberlite eruption 90 million years ago, an immense chunk of basalt country rock—about 1 hectare (10,000 square meters) wide and 150 meters deep—was detached into the southern section of the kimberlite pipe. This creates an immense waste expense and an obstacle to mining the pipe (see figure 6, bottom). Current plans are to mine the open pits until 2038 (Gem Diamonds Ltd., 2015b).

Letšeng produces approximately seven million metric tons of ore and 20 million metric tons of waste per year and employs local contractors for much of its mining activities, with the exception of blasting. Drilling is done with Atlas Copco Roc L8 and L6 machines. The mine employs a mixed loading and hauling fleet of Caterpillar 385C and 390D excavators, together with Caterpillar 773 (50-ton capacity) rigid-body dump trucks for hauling waste and Caterpillar 740 (40-ton capacity) articulated dump trucks hauling ore (figure 13). The mixed fleet is suited for handling different ore and waste profiles during various stages of mine development.

IMPROVING RECOVERY AT LETŠENG

Letšeng’s financial model is dependent upon its ability to recover large stones intact. Because of this, standard diamond recovery processes, which crush the ore into small pieces for fast, efficient recovery, cannot be used without major modifications. Gem Diamonds invested $9.9 million in new diamond processing technology to spare the large stones, all because of changes in the diamond market since the mine first operated in the 1970s and 1980s. As Gem Diamonds chief executive officer Clifford Elphick explained, prices for very large diamonds were relatively low compared to smaller stones, so it was more cost-efficient to damage such goods during processing in the name of speed. In recent years, however, the rising number of billionaires and ultra-wealthy connoisseurs has pushed prices of major diamonds to record levels. Now mines must increasingly focus on recovering these high-value stones—especially as they go deeper and mining costs rise.

After Gem Diamonds acquired a majority share of Letšeng Diamonds, the company built a second treatment plant that would double the mine’s capacity. The plant’s owners also introduced new technology to minimize damage to large diamonds and reduce construction and operating costs. The design of Plant 2 took advantage of the mine’s topography, with the processing plant set on a 17° slope. Material would be fed from the top end, letting it flow downward stage by stage through the separating and crushing processes, reducing the need for pumps and conveyors (Bornman, 2010). Plant 2 went online in the fall of 2008. Together the two plants treat 5.7 million metric tons of ore per year. An additional 1.3 million tons per year, mainly from waste dumps, are processed by an outside contractor, Alluvial Ventures, through their two plants.

The primary ore crushers break the large kimberlite blocks into pieces about 125 mm in diameter. From there the ore goes through a scrubbing process that uses vibration to remove excess clay, rock, and other foreign matter. In this process, the kimberlite pieces grinding together do the scrubbing without additional grinding agents that could damage the stones. From there they proceed by slurry to the coarse crushing, which sizes the material down to 45 mm diameter—a 200 ct rough is approximately 30 mm in diameter.

Although the company had recovered a number of large diamonds by 2013, executives remained concerned that major stones were not surviving the crushing process, particularly because Letšeng type IIa diamonds generally display excellent cleavage, and a significant proportion of them are cleavage fragments (Bowen et al., 2009). At the beginning of that year, the throughput of ore was deliberately slowed to allow closer observation of the conveyor to spot large stones (figure 14). After several months, though, there was still no clear correlation between processing speed and diamond damage.

In the second quarter of 2013, the company replaced the Plant 2 crushers, large steel jaws that broke the ore down to small pieces in three stages, with a cone crushing system, configured specifically for Letšeng’s production (Cornish, 2013). In this new system, the ore is loaded into a receptacle and passed over a rapidly spinning cone that also oscillates side to side, crushing the ore against the sides of the passage without exerting the diamond-damaging pressure of the jaw system (Gem Diamonds Ltd., 2014). Gem Diamonds subsequently replaced the crushers in Plant 1 as well. According to Letšeng Diamonds chief executive officer Mazvi Maharasoa (figure 15), the new crushers sized the kimberlite chunks into pieces roughly 50 mm (about 2 inches) in diameter, instead of 20 mm as in the past.

The result, beginning in May 2013, was an immediate improvement in the number of large diamonds recovered. From January through April 2013, Letšeng yielded one diamond over 100 carats and three diamonds between 45 and 55 carats (table 5). From May 2013 until year’s end, 17 very large diamonds were recovered, including one over 150 carats, three that were approximately 100 carats, and 13 between 60 and 80 carats (Gem Diamonds Ltd., 2014).

| TABLE 5. Production of large diamonds at Letšeng, 2005–2014. | ||||||||||

| Size (ct) | 2005 | 2006 | 2007 | 2008 | 2009 | 2010 | 2011 | 2012 | 2013 | 2014 |

| >100 | 6 | 5 | 5 | 7 | 5 | 6 | 5 | 3 | 7 | 7 |

| 60–100 | 7 | 14 | 9 | 16 | 10 | 10 | 19 | 13 | 16 | 21 |

| 30–60 | 30 | 40 | 39 | 74 | 76 | 61 | 59 | 61 | 50 | 69 |

| 20–30 | 49 | 47 | 65 | 88 | 98 | 89 | 91 | 110 | 71 | 101 |

| Total>20 ct | 92 | 106 | 118 | 185 | 189 | 166 | 174 | 187 | 144 | 198 |

|

Source: Gem Diamonds annual reports

|

||||||||||

After crushing, the kimberlite pieces are conveyed to the recovery area, where the diamonds are separated from waste rock by X-ray technology. XRL (X-ray luminescence) and XRF (X-ray fluorescence) units, developed in the 1980s, take advantage of the fact that diamonds will fluoresce when exposed to intense X-rays. The crushed kimberlite particles are dropped in a thin stream under a beam of X-rays. When a diamond fluoresces, it activates a photo-detector, triggering a jet of air that deflects the diamond into a collector box (Valbom and Dellas, 2010). Older X-ray recovery units identified diamonds by fluorescence alone, causing nonfluorescent diamonds (which include many type II) and some fancy-color diamonds to slip through to the waste piles. More recent methods adopted at Letšeng employ X-ray transmissive (XRT) technology before the crushing process to identify large rough type II crystals by measuring their specific radiometric response to X-rays and eject them from further processing (Cornish, 2013). The general principle behind XRT is that diamond shows up as a much brighter image than other Si-bearing minerals. Minerals containing Fe or heavier elements will show up even darker. XRT sorting does not rely upon a diamond’s transparency because it does not deal with visible light range. Even if the sample is sufficiently coated to be completely opaque, the XRT sorter will detect it. The company tested these X-ray units on tailings, recovering $12 million worth of diamonds over six months (Cornish, 2013; Gem Diamonds Ltd., 2014).

CHARACTERISTICS AND MARKETING OF LETŠENG DIAMONDS

The Letšeng mine is famous for its very large diamonds (tables 1 and 5). The largest, the Lesotho Promise (figure 16), was discovered in 2006. At 603 ct, it surpassed the 601.26 ct Lesotho Brown. Although only marginally larger, the Lesotho Promise is a type IIa diamond, and its absence of color resulted in a stunning collection of 26 diamonds of D color and Flawless clarity (figure 17). A significant percentage of diamonds from Letšeng have exceptional clarity and transparency, no fluorescence, and are classified as D-color and Flawless (figure 18). They are type IIa diamonds with roughly dodecahedral shapes; octahedral shapes are very rare, comprising less than 1% of the Letšeng population (Harris, 1973; Bowen et al., 2009; see box B).

| BOX B: MORPHOLOGY OF LETŠENG DIAMONDS |

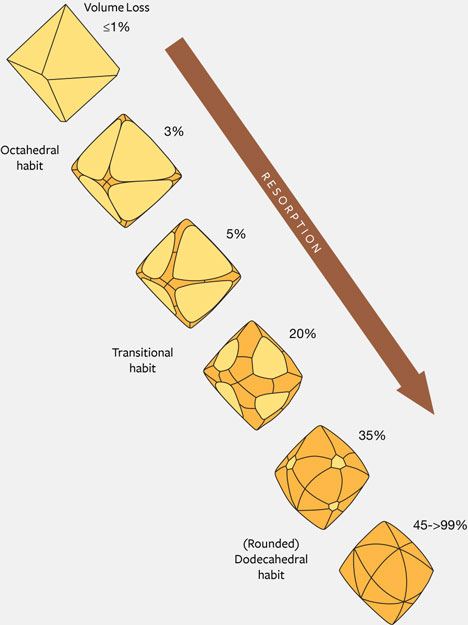

Figure B-1. With increasing resorption, the morphology of a diamond crystal changes

from octahedral to dodecahedral forms. From Tappert and Tappert (2011). |

| Several days of production at the Letšeng mine in September 2014 yielded the group of approximately 4 ct diamonds seen in figure B-2. Nearly all of them revealed strong resorption marked by smooth, rounded surfaces with indistinct features. The near-colorless and brown stones showed irregular shapes, typical of type IIa diamonds, whereas the three yellow type Ia diamonds in the center presented obvious dodecahedral forms. Of the larger stones in figure B-3 (approximately 8–10 ct range) that were available during the mine visit, all were near-colorless to slightly brownish with distinctive resorption features and irregular or elongate shapes, characteristics indicative of type IIa diamonds. |

Figure B-2. These diamonds, each weighing approximately 4 ct, represent several days of mine production at Letšeng in September 2014. Most crystals show strong resorption features and dodecahedral forms. Photo by Robert Weldon/GIA.

Figure B-3. Larger diamonds from Letšeng, like these crystals ranging from 8 to 10 ct, were usually type IIa with irregular forms. Photo by Robert Weldon/GIA.

|

| Letšeng diamonds are well known for some degree of dodecahedral form, with more than 95% of the recovered stones showing significant resorption effects (Bowen et al., 2009). The mine is also known for producing a high percentage of large type IIa diamonds of exceptional color and clarity, but with irregular crystal forms. The Letšeng mine production available to the authors was consistent on both counts. Type IIa diamonds from Letšeng usually have irregular shapes. The 22.87 ct type IIa stone in figure B-4 (left) has excellent color and clarity but no distinct form other than a single octahedral face with visible trigons. In contrast, type Ia diamonds show more distinct forms such as the partially resorbed 32.97 ct yellow octahedron in figure B-4 (right). Octahedral forms like this are relatively rare at Letšeng. |

Figure B-4. These two crystals from Letšeng illustrate the morphological differences between irregularly shaped type IIa diamonds such as the 22+ ct stone on the left and type Ia octahedral stones such as the 32+ ct stone on the right. Photos by Robert Weldon/GIA.

|

In 2014, Letšeng reported that it found seven diamonds over 100 ct. By year’s end it had sold five of them, which represented 14% of Letšeng’s total sales for the year. The mine recovered a record 198 diamonds larger than 20 ct, 54 more than the previous year. Letšeng’s 2014 production was valued at an average of $2,540 per carat, buoyed during the final quarter by the recovery of 13 large diamonds whose price exceeded $1 million each, including a 299.3 ct yellow diamond (price undisclosed), a 112.6 ct colorless diamond that sold for $5.8 million, and a 90.4 ct colorless diamond that brought $4.2 million (Max, 2015). In the first half of 2015, the average value slipped to $2,264 per carat, though 13 diamonds offered during that period sold for more than $1 million each (Gem Diamonds Ltd., 2015c).

The initial sorting and valuing is done at the mine site to satisfy the Kimberley Process (KP) requirements for export and to establish values for the government, which receives at present a 7% royalty based on value. From the mine they are exported to Antwerp, where they undergo another KP check before proceeding to the company’s sales office at Lange Herentalsestraat in the city’s diamond district. At the sales office, the rough is cleaned by an acid wash to remove all surface material and then revalued and sorted for sale (C. Elphick, pers. comm., 2014). During the sorting process, the Antwerp sales team first sets reserve prices on individual rough diamonds larger than 10.8 ct and then on parcels of smaller goods grouped by weight, quality, and shape.

Letšeng rough is offered ten times per year in online auctions conducted through its Antwerp office (figure 19). Diamonds larger than 100 ct are offered individually in special sales.

Unlike other smaller diamond producers, Gem Diamonds maintains its own sales office and does not employ a contractor. Selling its own goods in this manner provides Letšeng with complete flexibility over the marketing of its rough production, said CEO Clifford Elphick (figure 20), while reducing sales and marketing costs from 2.5% to 1.5%.

“We have about 150 customers for each sale,” said Elphick. “They have a ten-day viewing period to review the goods, and can bid up to the final minute.”

Unlike some rough diamond auction models where high bids are averaged into across-the-board prices for a particular category, the winners buy their lots for their high bid price. “Occasionally, if a bid seems unrealistically high, we will ask the client to review it,” Elphick explained. “Once in a while some people misplace a decimal point.”

Elphick noted that in the eight years of selling diamonds from Letšeng, both the sales staff and clients have developed a strong understanding of the goods and their prices, so the process usually runs very smoothly.

While the very large stones capture the headlines and high price tags, most of Letšeng’s earnings come from commercial goods (figure 21) and 5–15 ct goods, which actually achieve the highest per-carat prices. “We get prices over $50,000 per carat for the top qualities: type II goods of high color, which we call ‘Letšeng-y,’” he said. “The cutters like these because they are easy to work, with high yields. Many of them polish to D color—perhaps a little higher than a normal D, because they are type II with very little graining.”

In addition, the mine occasionally produces some fancy-color diamonds—two or three blues a year, and a larger number of pinks and yellows (figure 22).

Elphick explained that the explosion in the number of ultra-wealthy individuals over the past 15 years has sparked demand for large, high-quality diamonds, driving prices higher and making Letšeng profitable to mine again. But Elphick added that the per-carat price begins diminishing above 15 carats because of the risks still inherent in diamond cutting. “If they make a mistake on a ten-carat stone, it won’t put them out of business. But when millions of dollars are involved, they have to hedge a bit.”

Lots that do not sell at the company tender auctions are sent to contractors for polishing. These account for $15 to $20 million yearly, he said, noting that most of the buyers for polished goods are also the company’s rough clients.

All of Letšeng’s unsold rough is polished in Antwerp. Elphick and Maharasoa both stated that the plan is to establish a polishing operation in Maseru as part of a goal for the mine to contribute 15% of Lesotho’s gross national product. Elphick said that the company already has the space to begin a small polishing operation in the capital but is awaiting permits from the government.

“It could never become a large operation that would compete with those in India,” Elphick acknowledges, “but we can start small and see if we can expand later."

CONCLUSIONS

The Letšeng mine is a unique diamond resource whose economic viability has been realized by strong increases in per-carat prices for large diamonds since 2000. While earlier attempts to mine the deposit were unsuccessful because of the low ore grade and the challenges of moving equipment to a remote location high in the mountains of Lesotho, the mine’s current majority owner has invested in radically modified diamond recovery methods to greatly reduce the damage to large diamonds, particularly those above 50 ct. The company markets Letšeng’s unique production through its own sales office in Antwerp (figure 23), via regularly scheduled auctions. Despite the profitability, there is concern that the mining license is finite, expiring in 2019, and that a renewal may carry more costly terms. In a 2010 paper, Mazvi Maharasoa, CEO of Letšeng Diamonds, noted that operating costs of 70 million loti per year (US$6 million) were too high given the finite nature of the lease, the fluctuating exchange rates, and the costs of building and maintaining access roads and transporting supplies. Demand for very large diamonds such as those produced at Letšeng has remained high through turbulent economic times, and the mine’s operators are confident that it will continue to yield large diamonds, the sale of which will make headlines around the world.