Useful Visual Clue Indicating Corundum Heat Treatment

ABSTRACT

The heat-induced conversion of limonitic residues to hematite in surface-reaching inclusions provides another useful clue to heat treatment in corundum. Because this alteration happens at such a low temperature, it is virtually unavoidable, during even the most routine heat treatments. The resulting difference in color between the limonitic compounds and the hematite makes this transformation obvious.

INTRODUCTION

Jewelers and trade gemologists generally do not have immediate access to so-called advanced testing instruments of the type found in GIA’s laboratories. Instead they rely on traditional techniques taught in gemology courses to give them the results they need. Instruments such as the gemological microscope, refractometer, and spectroscope are their first and sometimes last line of defense. Therefore, any practical means of identifying treated gems is always welcome.

One such example of a straightforward and useful observation involves the heat-induced conversion of brown to yellow hydrous ferric oxides, such as goethite, to bright red to brownish red hematite. Hydrous ferric oxides are deposited epigenetically, after the formation of the host crystal. The deposits occur when hydrous ferric oxide–enriched groundwater invades a crystal’s surface-reaching features, such as partially healed secondary and pseudosecondary fractures, cleavage and parting planes, and growth tubes. The residual groundwater then dries out, leaving behind solid hydrated limonitic deposits inside the inclusions.

At first it might seem simple to duplicate this natural process, but that does not appear to be the case. Under geologic time and conditions, nature deposits these residues through capillarity and varying pressure over long periods, possibly exceeding many millions of years. This depositional cycle may also be repeated many times over.

In this manner, hydrous ferric oxide particles and other particulate residues too large to enter the voids are gradually sifted out. Particles suspended in the circulating groundwater that are fine enough to enter the voids are carried by the water and deposited in the inclusions, either as amorphous solids or as crystalline minerals such as goethite.

EXPERIMENTAL RESULTS

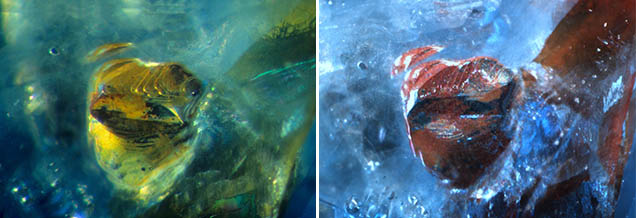

Since a picture is often worth the proverbial thousand words, two unheated natural Sri Lankan sapphires containing typical epigenetic limonitic residues were selected for experimentation. One contained a very intricate, partially healed fracture “fingerprint” decorated with an equally intricate pattern of brownish yellow epigenetic limonite (figure 1, left). As shown in figure 2 (left), the other sapphire hosted a blocky iron sulfide inclusion with a surface-reaching crack that allowed a thin coating of epigenetic limonite to form on the surface, giving the inclusion and the crack a yellow color. In the second example (figure 2) it is not entirely clear whether the epigenetic residue resulted from surface alteration of the sulfide inclusion, groundwater deposition, or both.

As previously stated, one of the primary mineral constituents of limonite is goethite, an orthorhombic mineral with the chemical formula α-FeO(OH). When these two epigenetically stained sapphires were heated in air to the relatively low temperature of 350°C, the goethite (limonite) yielded water and converted to the trigonal mineral hematite, α-Fe2O3, through the chemical reaction:

2α-FeO(OH) → heat 350°C → α-Fe2O3+H2O

The obvious change undergone in this relatively simple heat-induced conversion is evident when comparing the pre-treatment and post-treatment images in figures 1 and 2. While the limonite is brownish yellow to yellow, the hematite has a rusty-looking brownish red color (figures 1 and 2, right).

Given the low temperature involved, it should be evident that the alteration of limonite (goethite) to hematite could happen in virtually any other gem material during routine heat treatment. Two examples include the conversion of amethyst to citrine (Koivula, 1987) and the change of color shown by limonite-stained etch ribbons in so-called rutilated topaz (Kammerling and Koivula, 1989).

CONCLUSION

The field of gemology has become highly technical, and advanced testing using an expanding variety of machines is now routine in some situations. Still, traditional non-destructive gemological testing techniques should not be ignored or forgotten. Careful microscopic observation, refractive index, calculated specific gravity, a spectrum obtained through a handheld spectroscope, or screening with UV radiation still provide enough information to answer many critical questions. Applying those methods can eliminate unnecessary advanced testing, while also serving as a guide for further analysis.