Bench Tip #6: Use a Split Mandrel for Finishing Round Bezels

Finishing round bezels

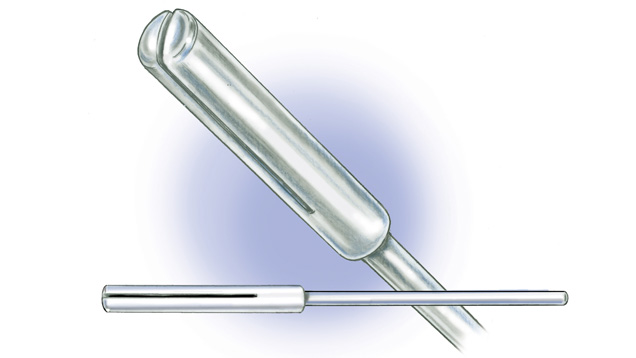

A bench jeweler typically uses a split mandrel to sand and finish the inside of a ring. Various grits of abrasive papers can be cut to size and inserted into the slit of the mandrel, where they are held by friction during the rotary filing process. With minor modification, you can use the split mandrel as a holding device to finish round bezels and other small jewelry components quickly and consistently.

You can modify a standard split mandrel so it will hold small jewelry components for finishing.

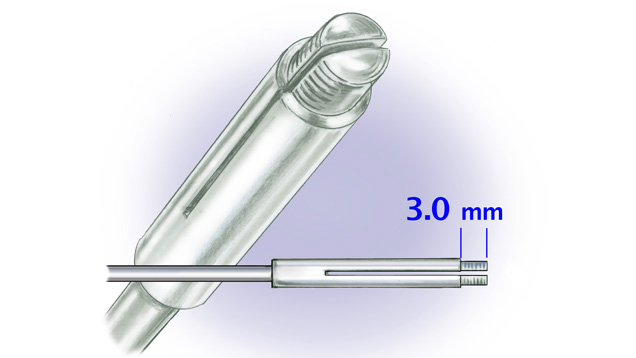

To illustrate this, we will make a bezel for a gemstone measuring 4.5 millimeters round. The bezel will be hand-fabricated from 4 x 1 mm sterling silver flat wire. To determine the length of flat wire required to fabricate the bezel, multiply the gem’s diameter (4.5 mm) by pi (3.14) to find its circumference, which equals 14.13 mm. The bezel is cut from the flat wire, formed, soldered, then rounded and trued. The truing step, typically accomplished with a ball- or setting-style bur, is critical to rounding the inside of the bezel.You will need to make a minor modification to the split mandrel to fit and hold the bezel for this use. Calipers, dividers and an equaling file will be required. The outside diameter of the split mandrel measures 5.5 mm and the inside diameter of the hand-fabricated bezel measures 3.5 mm, so the split mandrel must be filed down.

With the mandrel secured in the hand piece, brace it and start spinning the flexible shaft at a moderate speed. Place the equaling file flat against the mandrel shaft about 3.0 mm from the top of the tool and apply adequate pressure to begin filing down the mandrel shaft. Continue filing until the shaft diameter is reduced to 3.8 mm.

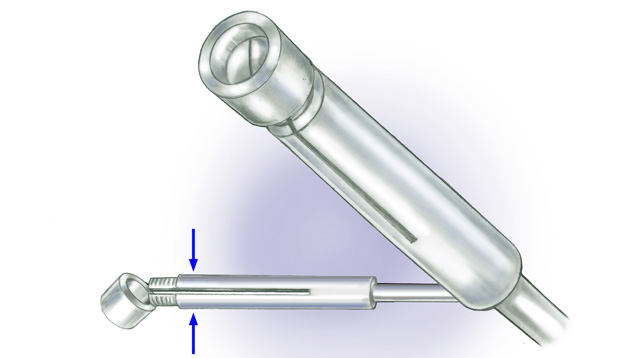

Next, squeeze the upper shaft of the split mandrel and place the bezel on it so it extends about 0.5 to 1.0 mm above the top of the tool. This makes it possible to sand the top of the bezel, too. The bezel will be held firmly in place by the tension of the split mandrel throughout the remaining steps in the finishing process.

This split mandrel has been modified by filing down the end of the shaft.

The flexible shaft can be spun at moderate speed, and a variety of abrasives can be placed against it to smooth and polish. This technique also gives you greater hand-eye control to apply the surface finish on small areas.

Place the bezel on the mandrel for finishing.

A modified mandrel gives you a dual-purpose tool for sanding or cleaning up bezels and other small parts. The next installment of the GIA Insider will present a stone-setting application using a different modification of the split mandrel.