Bench Tip #8: How to Use the Conduction Soldering Technique

Conduction soldering technique

The soldering process, used extensively in all aspects of jewelry manufacturing and repair, joins two or more pieces of metal together—and when done properly, will result in a virtually undetectable seam. A better understanding of the soldering process can help you decide how to approach a particular soldering project.Solder is a metal, usually quite similar to the original (parent) metal of the piece you are working on, that melts at a temperature slightly lower than the original. It is natural to think of the solder as a kind of glue that is heated up to hold two pieces together. But thinking about it this way can lead to problems: If you point the soldering torch directly at the piece of solder to melt it, the solder will overheat, boil, and oxidize. Many times it will stubbornly refuse to melt into the joint, regardless of the amount of heat applied.

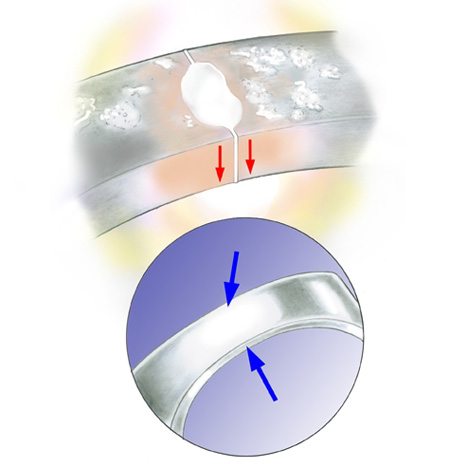

For this reason, you can solder precious metal by using a technique called “conduction soldering.” In this process, the parent metal is heated to a point close to its melting temperature. That heat is transferred to the piece of solder, which is drawn into the joint by a process called "capillary action." This makes a strong solder joint by properly bonding the metal.

Follow these important steps to prepare for successful soldering:

Prepare the joint. The two pieces of metal to be joined should fit together well. Soldering works best when the pieces are in full contact with one another. Solder should not be used to fill gaps, because that will lead to weak and detectable joints.

Do not point the torch directly at the solder. From inside the ring, gently move the flame back and forth below the joint. The heat will be conducted upward, and when the joint area is the proper temperature, the solder will flow.

Use a “firecoat” and flux. Firecoat is a protective coating placed on the surface of the jewelry object to prevent surface oxidation. Soldering without firecoat will often cause discoloration (firescale) that can be very difficult to remove.

Apply the flux directly onto the joint prior to soldering. This chemically cleans the metal surface so the solder can bond with the parent metal.

Heat from beneath the joint draws solder in to bond with the parent metal (ring shank). The bottom illustration shows the finished ring with no visible solder seam.

After the joint is prepared, heat the object using the conduction soldering technique explained above. Remove the heat as soon as the solder melts—overheating can cause the solder to boil, which will result in a pitted appearance and weak solder joint.

With practice, you can achieve strong and attractive solder joints on your precious metal jewelry.