Bench Tip #16: How to Modify a Goldsmith Hammer

Modify a goldsmith's hammer

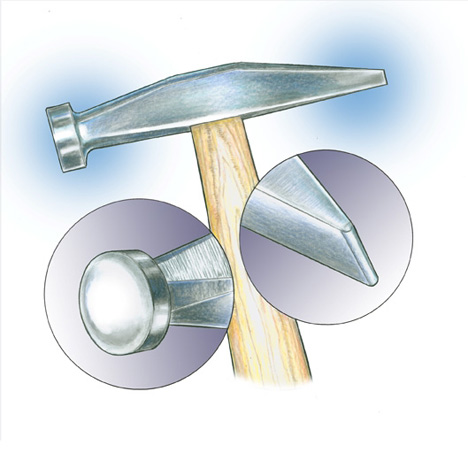

Jewelers and metalsmiths have had to make their own tools throughout the ages to accomplish different tasks at the jeweler’s bench. One tool a jeweler can’t do without is a hammer. Today, many styles of hammers, made in a variety of shapes and materials, are available to the jeweler. The hammer used here as an example of how to make modifications is used for riveting, shaping, forming and working on rings for sizing. The hammer has one round/slightly contoured end (called the pean) one chisel-shaped end and a hardwood handle.

Two modifications that are crucial to a jeweler will be made to:

- The handle, which is key to maximizing its effectiveness at achieving its specific task

- The round/slightly contoured face and the chisel-shaped heads

A hammer handle that is too long will not be balanced, and can cause fatigue. If it is too short, it reduces the amount of force you can apply with the hammer. The length of the handle can be modified to fit your hand by measuring from the tip of your thumb to the tip of your pinky, with your hand spread out. Alter the length of the handle, by cutting it down, to help you apply the maximum force to the object.

Next, you can modify the hammer heads by contouring and polishing them. Make a stack of paper on your work surface and place abrasive paper on top. Move the hammer in a circular motion over the paper to shape it. The stack provides a cushion so you can more easily modify the head. Work with sheets graduating grits of abrasive paper, from coarse to fine.

You will achieve the maximum potential of your goldsmith hammer by modifying the round

(top) and chiseled (bottom) heads. Polish with tripoli and rouge on a hard felt buff. This will

give the surface of the round head a slightly convex shape, reduce the sharp outside edges,

and leave a polished surface with minimal tool marks. If you don’t polish the head, the

surface marks will transfer to the metal you are working on when struck.

(top) and chiseled (bottom) heads. Polish with tripoli and rouge on a hard felt buff. This will

give the surface of the round head a slightly convex shape, reduce the sharp outside edges,

and leave a polished surface with minimal tool marks. If you don’t polish the head, the

surface marks will transfer to the metal you are working on when struck.

You should apply the same modification to the chiseled end of the hammer head. Instead of a circular motion, however, use a back and forth motion that follows that end’s contours. The goal is to put a convex surface on the end face and to round over all edges and corners so they don’t leave deep, hard-edged marks in the metal you work on. Use the same materials and set up you used to finish and polish the hammer’s round face.

These two modifications will help you achieve the maximum potential of your goldsmith hammer.

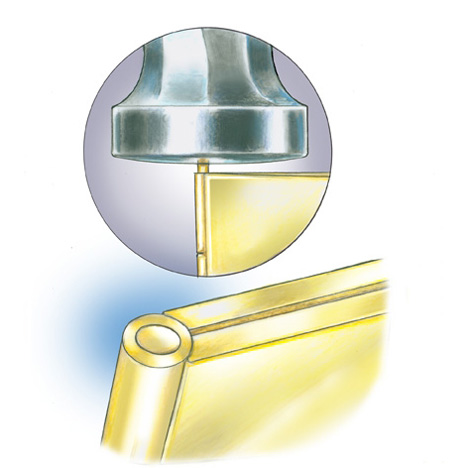

This goldsmith hammer is being used to tighten a hinge pin.