Bench Tip #14: How to Handle the Flexshaft and Handpiece

Flexshaft and handpiece

Here are a few observations that can make your equipment last longer and prevent possible injury.The flexible shaft machine, commonly called a “flexshaft,” is a combination of a motor, handpiece and the flexible shaft that connects the two. The machine is usually operated by a foot pedal. Because jewelers often use more than one handpiece during the workday, the procedure of connecting a handpiece to the flexible shaft is a common operation, but is often done incorrectly.

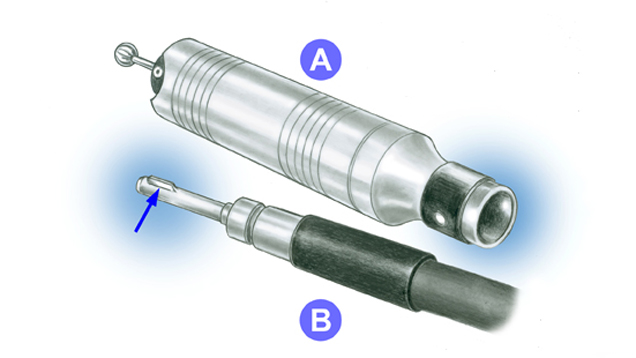

The handpiece (A) fits onto the end of the flexshaft (B), but must be properly aligned.

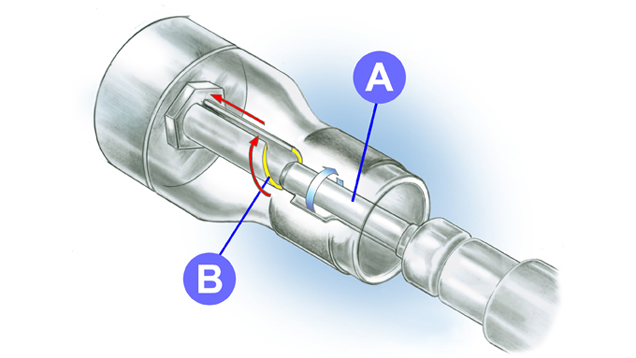

The end of the flexible shaft is a “keyed tip” that rotates when the foot pedal is depressed. When connecting the shaft to a handpiece, it is essential to fit this keyed tip into the slot inside the cover of the handpiece. Since the slot is inside the handpiece, it is difficult to see.

The rotating keyed tip portion of the flexible shaft (A) fits and slides into the locking mechanism of the flex shaft handle (B).

If the flexshaft tip is pushed into the handpiece without aligning the key to the slot, there is potential for equipment damage and personal injury:- Sometimes the key will rotate and drop into the slot when the pedal is depressed, but this will eventually wear down the key.

- The shaft can also bend the connector inside the handpiece, causing it to jam and the handpiece to violently jerk if the pedal is depressed quickly. This can cause injury or damage the flexshaft or handpiece.

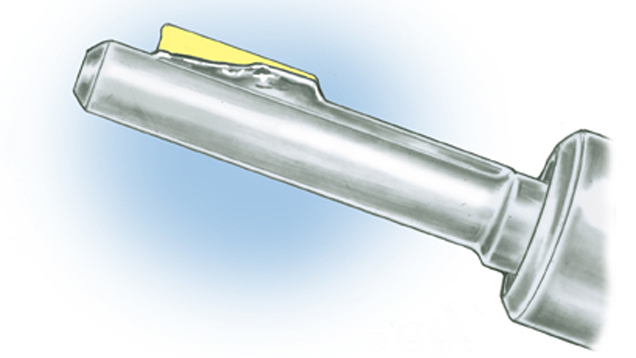

If not inserted properly, the keyed tip will wear down and eventually fail.

To make sure the key and slot are properly aligned, some jewelers will look down inside the handpiece to find the orientation of the slot, then turn the handpiece as needed so the key drops in. This works, but here is a fast and simple way to make the connection:- Slightly depress the foot pedal so the shaft is turning slowly, then insert the shaft into the handpiece and gently push.

- You will feel the key drop into the slot and can see that the connection is correct when the handpiece begins to move (rotate or hammer, depending on the handpiece).

- Now you know the key and slot are properly aligned and it is safe to snap the shaft the rest of the way into the handpiece.