Bench Tip #17: Avoid Stone Loss with Quality Assurance Benchmarks

Avoiding Stone Loss

Fine jewelry represents much more than its trade value in diamonds, gemstones and precious metals. It is a personal representation of the owner’s lifestyle, status, emotion, recognition, commitment and more. That significance only amplifies how devastating the loss of a gemstone is for the owner. Even one missing accent stone renders the jewelry unwearable. Loss of a significant gemstone will also impact the retailer who sold the piece and the manufacturer who engineered and produced it.The loosening, damage or loss of gemstones in jewelry can be attributed to two factors: poor workmanship or the absence of benchmarking standards for setting. Benchmarks are specific parameters used to compare and evaluate the acceptability of a finished product for market.

Stone loss can be avoided. Inspecting each piece and comparing it against established benchmarks for signs of vulnerability in normal wear gives the jeweler/manufacturer an opportunity to address potential problems before jewelry is offered for sale. Adopting consistent task-specific benchmarks encourages sound design and good workmanship, assuring the quality of jewelry for the consumer.

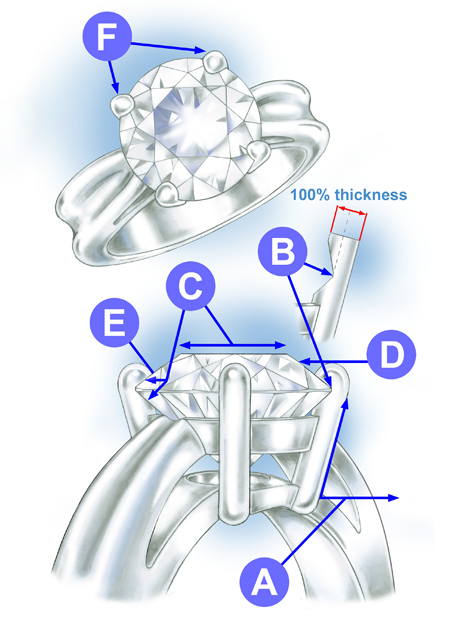

Examples of the quality assurance benchmarks presented here are for setting round brilliant gemstones in traditional angled prongs.

This drawing shows benchmarking criteria for angled prongs on a center stone.

Prong Setting Benchmarks – Traditional Angled Prongs A: Prong angle is 70-80 degrees.

B: Sufficient prong thickness is needed to secure the stone in place, so 40-50% of the metal is removed from the prong thickness at the bearing.

C: Diamond is seated level in the bearing just above the gallery wire. There are no gaps in any bearing – the bearing is the cut made in a prong and must precisely fit the stone contour when properly set. Any gaps will allow the stone to move or loosen.

D: Finished prong height is 75-85% of table height. Ample prong height allows the prong to hold up through normal wear.

E: Prong contact is 33-50% of total crown distance. Adequate prong contact over the crown is critical to a stable setting.

F: Prongs are rounded, polished and consistent in size and shape.

Potential Errors in Workmanship for Traditional Angled Prongs

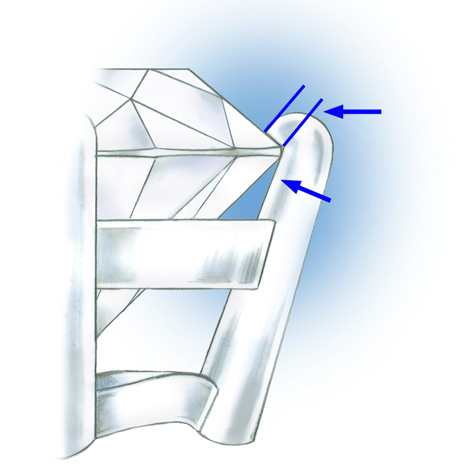

Example 1: Using benchmarking quality assurance benchmarks, you will note a bearing was not cut (lower blue arrow) and the diamond is not seated. Prong contact is insufficient (upper blue arrow) and barely secures the diamond.

This center stone has no bearing.

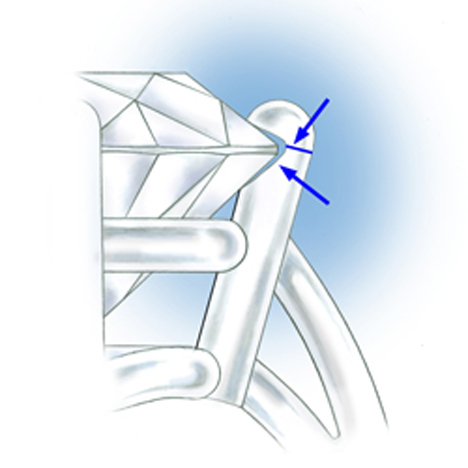

Example 2: The bearing does not conform to the crown and pavilion angles of the diamond, so there are large gaps. Too much metal was removed from the prong thickness.

This prong is overcut and there is visible open space at the bearing.

Understanding what to look for and following consistent quality assurance practices will enable our industry to ensure that our global consumers have the best possible jewelry experiences.