Mozambique: A Ruby Discovery for the 21st Century

December 3, 2014

Introduction

Gemfields’ first Mozambique ruby auction took place in Singapore from June 12–17, 2014, and marked a milestone for the global ruby trade. Unlike diamonds, colored stones face dramatic supply fluctuations, and pricing has always been problematic. The Gemfields operation offers the trade an opportunity to expand the consumer base for responsibly sourced, consistently graded, and reliably supplied ruby. The US$33.5 million revenue generated by the inaugural auction put the spotlight on one of the world’s largest ruby deposits, located in Montepuez, Mozambique.Advanced knowledge and up-to-date trade information have always been at the center of GIA’s consumer protection mission. Since the first Mozambique ruby discovery, GIA field gemologists have been first to appear at Montepuez mining sites to collect samples, witness progress, and document the entire mine-to-market process. GIA’s field gemology program is designed to help the public benefit from the first-hand knowledge obtained.

In September 2014, GIA researchers Tao Hsu, Vincent Pardieu, and Andrew Lucas, visited the Montepuez ruby deposit. This was Vincent Pardieu’s third visit since its discovery in 2009. The team was able to witness the evolution of this major deposit. Pardieu noted that it was uniquely situated to succeed, with its rich and easily mined resources and convenient location near a major port and well-traveled roadway. This report presents a complete update on the deposit and the bulk sampling and distribution of its gems.

Our host, the Montepuez Ruby Mining company (MRM), is currently still in the bulk sampling stage. This involves the removal of large mineralized rock, typically from small pits. The rock is selected to represent the potential ore body and used to perform mineral processing tests as required for resource estimation. This will facilitate any future decisions to be made about building large-scale mine operations. All production currently being sold at auction is the direct result of this bulk sampling process.

The Country of Mozambique

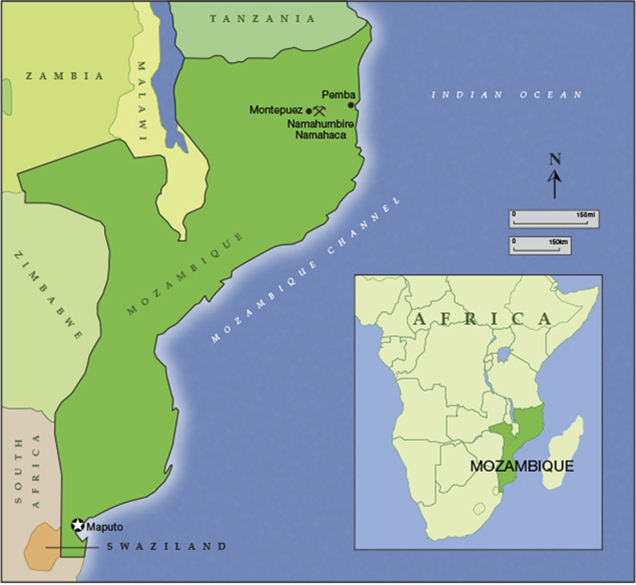

Mozambique is located in southeastern Africa along the Indian Ocean. Separated from Madagascar by the Mozambique Channel, it is bordered by Tanzania to the north, South Africa to the south, and Zimbabwe, Malawi, and Zambia to the west. Its total area is 801,590 square kilometers, about twice the size of California. Mozambique has 2,470 kilometers of coastline, much of it very beautiful. The climate is mostly tropical.

in the world. Its ruby mines are concentrated in the country’s northeastern corner. Illustration by Peter Johnston/GIA.

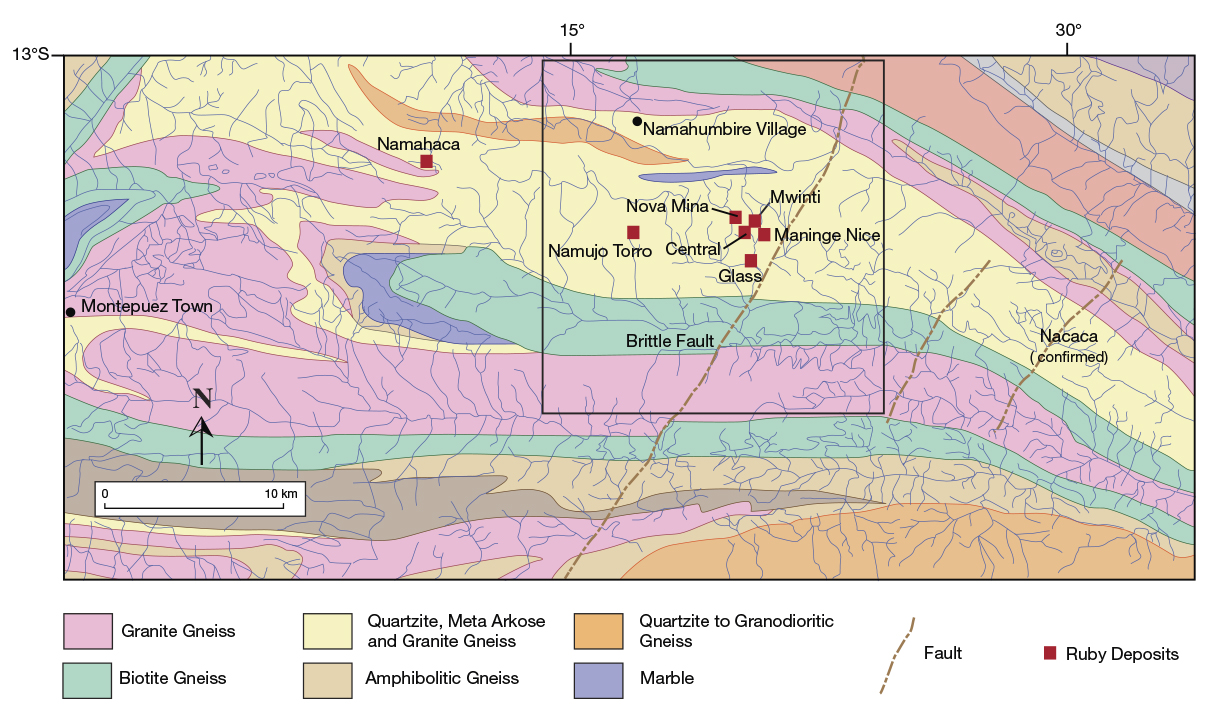

Map adapted from Richard W. Hughes, 2009.

While Mozambique has been hindered by poverty and reliance on foreign aid, its economy grew at an annual rate of 6% to 8% in the decade leading up to 2013, one of Africa’s strongest growth periods. Its rich resources of natural gas, coal, titanium, and hydroelectric power may lead to substantial foreign investment and put the country on the path to economic independence.

History of Ruby Discoveries

The history of corundum in Mozambique can be traced back to the colonial period, which lasted from 1505 to 1975. While corundum had been discovered in the 1500s and was known to exist throughout the colonial period, no real commercial exploitation had taken place. In the spring of 1991, Gems & Gemology reported the sale of cabochon-grade rubies from Mozambique at the Tucson show. Little more was reported until 2005, when author VP first heard about rubies from Mozambique while speaking with Thai heat-treaters (“burners”). They informed him that some of the material being treated came from Tanzania and Mozambique.In 2008, reports surfaced in Tanzania of a ruby deposit in Mozambique. Indeed, rubies were discovered by local hunters near M’sawize village, inside the Niassa National Reserve. GIA published a preliminary study on these stones by Pardieu and Thanachakaphad (2009). The site was mined illegally for several months before being closed by the authorities in the summer of 2009. The closure of that deposit was quite successful as most of the illegal miners, known as garimpeiros, moved to the Montepuez area in the Cabo Delgado province, where in April 2009 another ruby discovery occurred near Namahumbire village. This time, a local man named Suleman Hassan happened upon the gems while chopping wood.

In September 2012, GIA’s field gemology team returned to the site. This expedition resulted in a complete study of Montepuez ruby samples, which was published on GIA’s website. The most encouraging recognition of this joint venture was a visit by the president of Mozambique on April 20, 2013.

In June 2014, Vincent Pardieu and Andrew Lucas traveled to Singapore to report on MRM’s first ruby rough auction. They subsequently visited MRM and Mozambique in September 2014 to collect new reference samples and prepare an update on bulk sampling activity there. While the public is largely unaware of Mozambique as a source for rubies, the deposit near Montepuez is considered by the trade to be the largest ruby supplier in the world.

Mozambique Ruby Timeline (PDF)

Geology

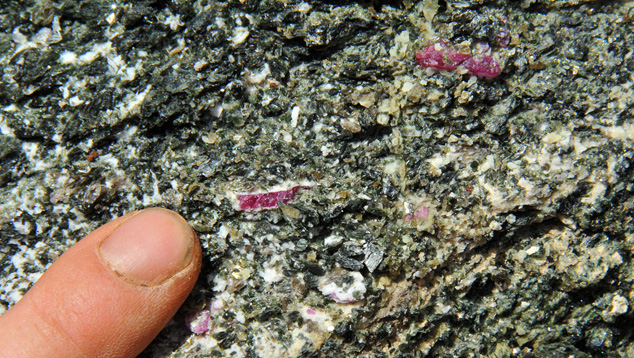

Northeastern Mozambique is located at a geologically critical junction between the north-south trending Mozambique Belt and the east-west trending Zambezi Belt. Both are “treasure-bearing” Neoproterozoic (approximately 800–500 million years old) orogenic belts within the global Pan-African tectonic framework. Several major geological complexes are separated by major thrusts and shear zones. Complex thermal and deformational events provided ideal temperature and pressure for forming ruby, garnet, and other economic minerals.About 150 km to the west of the beautiful coastal city of Pemba lies the Montepuez ruby mine. It's located within the wedge-shaped Montepuez Complex. Its mineral assemblages indicate that the whole complex underwent amphibolite-grade metamorphism (generally at a pressure of 0.4–1.1 GPa and a temperature of 550–750°C).

The Montepuez ruby deposits are both primary and secondary. Ruby forms only under a limited range of pressure-temperature conditions and only with a sufficient supply of aluminum and chromium and oxygen. Around Montepuez, the ruby formation seems to result mainly from a metasomatic process. So far, rubies have only been found associated with feldspar, mica, and amphiboles in amphibolite. No rubies have been found in the marble.

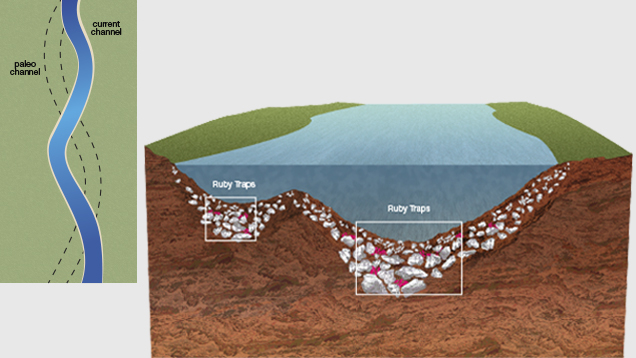

Paleochannels and Ruby Traps

The eternal cycles of weathering and erosion are constantly shaping the surface of the Earth. Once the ruby-bearing rock has been weakened and broken down by physical and chemical weathering, it is ready for erosion, which occurs when rock fragments or sediments are picked up and relocated. In Montepuez, rubies and other minerals liberated from the parent rocks by weathering were picked up by water and, due to their high specific gravity and hardness, trapped and concentrated in certain locations along current or former river beds, above the weathered basement rocks. Another constant is the change of river channel morphology over time. These stream channels have changed considerably over millions of years, but they might offer the explorer some hints on finding the old channels known by geologists as “paleochannels.”

Pit 3 in the Mashamba area, the largest pit being worked by MRM, is located along one of the main paleochannels identified by company geologists. On the wall of this pit, some superb cross-sections of former river channels can be observed. From the edge to the bottom of the “traps,” there is a clear increase of gravel size. Due to gravity, heavier gravels tend to settle and concentrate at the bottom of a depression. The larger gravels slow the water speed more than the smaller gravels. Since the specific gravity of ruby is relatively high, it tends to settle along the bottom of a depression with other heavy minerals. When the flow speed slows, it also favors the deposit of rubies. Thus, a higher concentration of ruby can usually be found at the bottom of the trap. Traps for heavy minerals occur at different positions along the river channel, wherever the water current slows. The traps themselves work as natural jigs, and these ruby “traffic jams” are ideal locations for gem hunters.

The Mine

The total size of the MRM concession is roughly 400 square kilometers. The mine has both primary and secondary deposits, but most of the bulk sampling takes place at the secondary deposits. Bulk sampling is planned for both types within the current fiscal year.MRM gives its bulk sampling pits numerical names, but many go by the original names used for the area. The only pit with a primary deposit as well as secondary gravels being sampled is at Maninge Nice, a local name given because of the “nice” stones that have come from there.

Bulk Sampling Methodology

MRM emphasizes the secondary deposits, which are easier to sample and host a concentration of fine stones because most of the fractured and included stones were ground into sand by weathering. However, perhaps their most important reason for focusing on secondary deposits is to protect them from being exploited by unlicensed miners.

Further Exploration

MRM’s resource estimation is scheduled to be completed in 2016, and this will give a clearer picture of the potential production figures and the life of the mine. Exploration is in progress for both the primary and secondary deposits. Different drilling methods and strategies are applied to each type.The goal of the secondary deposit exploration is to better define the distribution of the ruby-bearing gravel layer in the MRM concession. Contours of the gravel layer will be constructed from this, as well as data on the concentration of rubies.

to complete the drilling. Photo by Andrew Lucas/GIA.

Gemfields’ geologists divided the target area into blocks and planned to drill boreholes in 100-meter grids, with a borehole placed at the center of a square and at each of the four corners. They will adjust the distance between boreholes if there is variation in a certain area. Near the former river bed, for example, the distance between drill holes can be reduced to 25 meters. GIA has not seen much of the auger drilling technique being used before for alluvial colored gemstone mines.

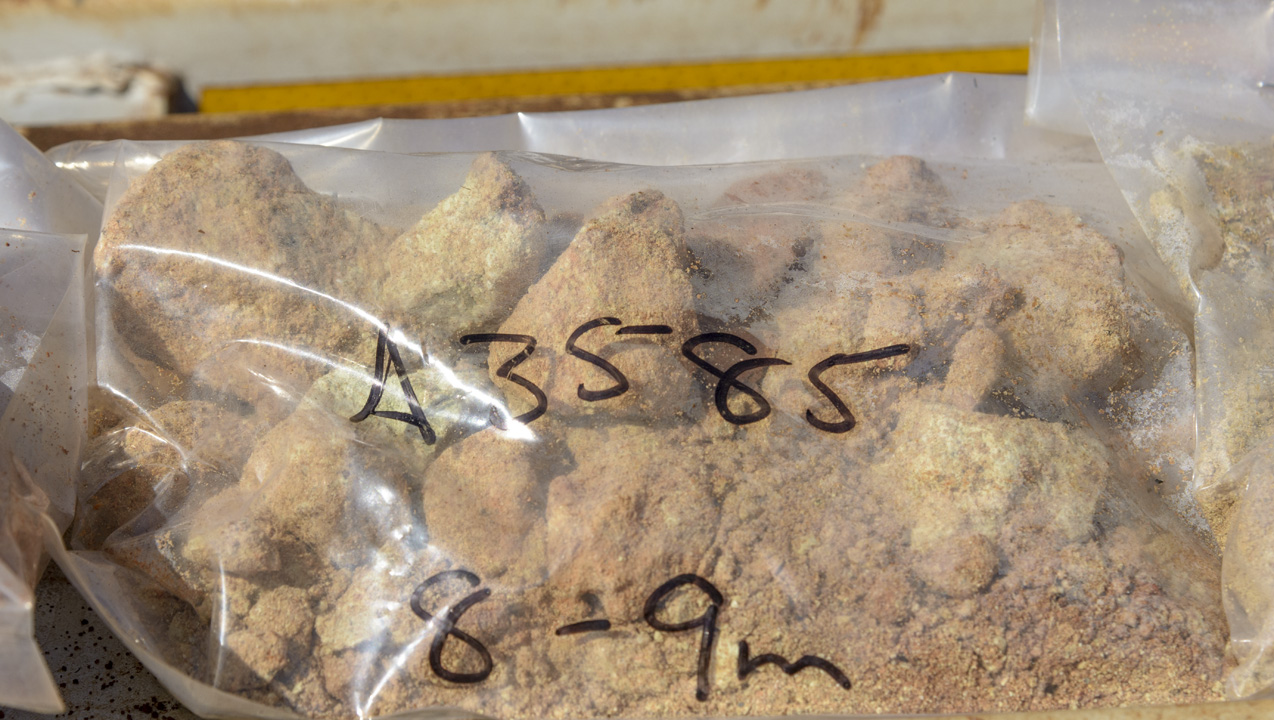

The drill bits and other equipment are hauled by truck to drilling sites. Every exploration team is composed of a geologist, a technician, and four or five workers. From setting up the machine to refilling the borehole, it takes about an hour to finish one spot. The goal is to finish eight to nine drill holes each day. The sites are already cleaned and prepared before the drilling starts.

From ground level, the drill will remove one meter of earth with every sampling until it hits the basement rock. Then the drill will keep removing 2–3 meters of basement rock before it stops. The average depth of the drill holes is about 8 meters, and each day the team needs to finish about 70–80 meters of drilling. MRM runs two shifts per day.

The drilling results will indicate the depth and thickness of the ruby-bearing gravel layer at each location. After thousands of drillings are done, a contour map will be constructed to show the depth and thickness of the gravel bed in the whole area. Prior to our visit, auger drilling had already helped delineate a continuous paleochannel 2.5 km long, as well as many other sites with strong potential. Sampling the topsoil also gives the geologists a good idea how much waste they will need to remove before reaching the ore-containing gravel layer.

To get a representative sample, each meter of earth removed from the drill bit above the ruby-bearing gravel layer is thoroughly mixed by a method called coning and quartering. For every meter, the geologists take 50–100 grams of sample for geochemical analysis to quantify certain elements that will guide further exploration and evaluation. When the drill hits the gravel layer, 10–20 kilograms of the ruby-bearing gravel are bagged and transported back to the washing plant and the sorting house for processing in order to get a rough estimation of the ruby concentration. The top 1–2 meters of the basement rock are also washed to minimize the risk of losing rubies. The leftovers from all samples are carefully stored for future reference. The process is completed by refilling the drill hole in an environmentally responsible manner.

Different mineral assemblages in rocks give off different magnetic signatures that can be displayed by a detailed magnetic scan. The results are used to model the distribution of certain rock types. Amphibolite usually gives a high magnetic anomaly that is easily distinguished from other rocks in this area. A high-resolution magnetic survey helps the geologist form a map pinpointing the location of the amphibolite. Next, a radiometric survey on uranium, thorium, and potassium is applied to detect the alkaline magmatic intrusions in the area. Further exploration plans are based on these results.

Exploration of the primary deposit is done by extensive core drilling around the currently exposed Maninge Nice area, and the goal is to better define the 3-D distribution of the ruby-bearing amphibolite below the surface. Each drilling extends about 50 meters deep and takes one week to finish at an average of 10 meters in depth per day. Drill bits coated with synthetic diamond are used to sample the rock every meter, a depth dictated by the length of the bits. Following a similar strategy to the one at the secondary deposit, the exploration team positions drill sites every 100 meters. When more lithological variation is observed, the distance is shortened to 50 meters.

Through extensive core drilling, the geologists have made some crucial discoveries underground. The ruby-bearing amphibolite is usually found at a depth of 10 to 30 meters. Each core starts with the topsoil, which is bagged because it is loose. Sometimes, a secondary ruby-bearing gravel bed is found above the primary deposit. The amphibolite with ruby can extend to 30 meters deep, and then it gradually changes to granitic gneiss, the basement rock in the area. They drill down the basement rock as well to see if the amphibolite repeats.

Production

Thus far, as part of its bulk-sampling operation, MRM has handled around 1.8 million tons of rock at Montepuez, recovering approximately 8 million carats of ruby and sapphire of various colors. The company hopes to double their capacity to 3.6 million tons of rock in 2015 and eventually increase that figure to 10 million tons of rock a year.The actual recovery of ruby is more difficult to predict. The amount of ruby per ton can vary greatly in the gem-bearing gravels of the secondary deposits. The quality of the rubies recovered can also vary greatly. Again, using Mugloto pit 3 as an example, the recovery rate is relatively low: 0.60 grams to 1 gram per ton of ore processed. Yet pit 3 yields high-quality ruby, making it economically advantageous to mine, even with the low recovery rate. This pit also produces some large rough crystals of six to eight grams. Compare this to Maninge Nice, which has a higher recovery rate of 20 to 35 grams per ton but produces much lower-value material overall.

Overall, the recovery rate for the primary deposit is around 162 carats per ton, while the secondary deposits bring 31 carats per ton. The figure for the secondary deposits only includes gravels processed and not the overburden topsoil moved.

Washing

The Montepuez processing plant was recently expanded to reach a capacity of 150 tons per hour, and there are plans to increase that by an additional 250 tons per hour. The processing plant is organized into four major areas: (1) dry screening, (2) disintegration with a log washer, where the removal of waste particles with water begins, (3) wet screening, and (4) sizing and concentration. In an auxiliary section, water is held in a reservoir and cleaned for use in washing.

One amazing sight was watching the suction hose remove the gravels in each section of the jig as it worked its way toward the bottom. As the suction hose pulled out gravel, we saw more and more red. When the gravel was nearly gone, the jig was almost completely red as the ruby’s higher specific gravity caused it to concentrate at the bottom. We had never seen such a concentration of gemstones in a jig.

Sorting

The washed gravels are taken from the processing plant to the sorting house. The concentrated gem gravels are loaded into the back portion of a sorting box, a rectangular case with an angled glass window for viewing. This is the first step in separating ruby from the gravels and garnets.The sorters never actually touch the rubies. They put their hands in sleeves with rubber gloves at the ends. This helps reduce the possibility of theft. The stones retrieved are dropped into two holes, one for garnets and the other for corundum. The sorters make the identification based on visual appearance, especially crystal morphology. The rubies are separated from the gravels and dropped into the ruby hole.

Photo by Andrew Lucas/GIA.

The corundum crystals are cleaned and sorted into classifications. First, the rough is divided into dark and light tones, representing ruby and pink sapphire, respectively. The rubies are classified into four further categories: premium, facet-grade, translucent to opaque material, and just corundum. The premium and facet-grade stones are graded for clarity, color, and carat size.

Two young Burmese graders from Mogok were grading the clarity. We spoke with them, and both were excited about this deposit and the chance to see so much ruby rough in a wide range of qualities.

The Gemfields ruby grading system was developed by a team led by MRM’s Philippe Ressigeac, a gemologist who graduated from GIA Thailand in 2009. The system is based on the rough’s size, color, shape, and clarity.

Reference Sample Collecting

GIA’s Bangkok lab has been collecting reference samples and mining information since 2008. The team’s current main focus is to collect and study ruby, sapphire, and emerald reference samples based on GIA’s protocols.In 2009 and 2012, teams led by author VP traveled to African mining sites before they were even in production. Reference samples were collected from the sites and from some West African dealers in Mozambique as well as Thai merchants based in Bangkok or Chanthaburi, Thailand. During the September 2014 expedition, samples were collected from the Mugloto and Maninge Nice pits.

These valuable reference samples, collected onsite, will be important additions to the GIA reference sample database. They are especially valuable because they are type A samples. This means they were mined directly from the rock by the gemologists themselves.

At the time of our 2012 visit, MRM was only processing gem-rich ground from Maninge Nice. As a result, we could not find samples at the Mugloto pit. Some samples from that area’s production from the previous month were selected at the Gemfields sorting house. The samples were collected at the mine, by the miners. Since GIA did not witness the actual recovery, the samples will be classified as C type samples.

On September 10, 2014, author VP and expedition guest Stanislas Detroyat accompanied the Gemfields geologist to the Nacaca area outside of the company’s concession. They documented mining activities and collected onsite reference samples from several garimpeiros, either at their washing area or at their camp. All samples gathered from this trip will be shipped by Gemfields to GIA’s Bangkok lab for analysis and a forthcoming research paper on country-of-origin determination.

Preliminary Gemology

Rubies from Montepuez are very important to the trade because of the large quantities and the wide range of qualities and sizes produced.Their colors bridge the gap between those from the classic sources of Burma (highly fluorescent, with low iron content) and Thailand/Cambodia (weakly fluorescent, with high iron content). While rubies owe their red color to chromium, their color is modified by the presence of iron, which reduces the chromium-caused fluorescence. An interesting aspect of rubies from the amphibole-related deposit near Montepuez is their range of iron content, from nearly as low as Burmese marble-type rubies to as high as rubies found in basalt-related deposits along the Thai-Cambodian border. This means they can potentially suit the tastes of a range of different markets.

Regarding quality, a small but significant percentage of the material has a combination of color and clarity that requires no heat treatment. But most of the rubies lack transparency due to fissures or the presence of inclusions. Heat treatment transforms this lower-quality material so it can find a market within the jewelry industry. Lead-glass filling is used for heavily fractured stones, while more traditional heat treatment (with or without borax-like additives) is performed on less-fractured stones with a milky or silky appearance. Overall, treated products are much more readily available than unheated.

A study on the gemological characteristics of the 131 ruby samples from Mozambique was completed by GIA’s Bangkok laboratory and published in 2013. Studies of inclusions and chemical composition are in progress, and the results will be presented in future articles.

Gemfields, Mwiriti, and MRM

Gemfields is a publicly traded company listed on the London Stock Exchange. Their goal is to be the world’s largest supplier of colored gemstones. They boast a tremendous amount of geological and colored stone mining expertise, along with proven grading and market strategies. Through its Kagem emerald mine in Zambia, Gemfields already has a history of successful emerald auctions. They also have experience in forming mining partnerships with governments and local communities and the capital to bring in any needed expertise and resources.

The Montepuez Ruby Mining Company is the corporation formed by Mwiriti and Gemfields. Gemfields has a 75% interest, Mwiriti 25%. MRM was formed in June 2011 with a joint venture agreement, and in November 2011 the corporation acquired a 25-year concession. The company actually has two concessions. MRM’s goal is to be one of the leading ruby suppliers in the world. Acting as a local company, Mwiriti is responsible for creating the right business environment and guiding Gemfields in its dealings with the national and local governments and community leaders.

Business issues include taxes, equipment imports, gemstone exports, and social programs for local communities. Mwiriti had experience with the same matters through its hunting concessions. They speak the language and know the locals, which was highly valuable in moving this project forward. Mwiriti was able to talk to the community leaders and find out what they needed.

Since export of gemstones was not an area that tax authorities in Mozambique had a great deal of experience with, Mwiriti was able to help Gemfields communicate with tax and export authorities to work out mutually beneficial arrangements. Much of the equipment MRM imports into Mozambique is new to the country and specialized for colored stone mining. Getting the equipment into the country in a timely fashion has involved learning how to deal with customs and import duties. Equipment also constantly requires maintenance, parts, and replacement, so a working relationship with Mozambique import officials is critical.

Security and the Garimpeiros

Mohun Raman is the head of security at the Montepuez ruby mine. He told us that internal security procedures, including checkpoints and searches, have greatly deterred theft at the bulk sampling, processing, and sorting areas. However, external security concerns remain one of the biggest challenges the company faces today.

MRM security actually consists of three organizations: MRM’s own security staff, composed of thirteen expats and about 125 local employees; a private security agency, ARKHE, that has an onsite expat security manager and around 250 guards; and a uniformed and armed government police force, the FIR, with about 30 men.

staff leave the mine facilities. Photo by Vincent Pardieu/GIA.

Inside the MRM concession are two villages, Namutcho and Namahumbire. These villages, as well as Nanhupiu, which lies just outside the concession on the road to Pemba, offer logistical support for the unlicensed miners: restaurants, blacksmiths, shops, and mining tools such as torch lights and picks. The residents of Namutcho and other villages near Ntorro and Mugloto were supposedly being relocated and compensated. When asked if the local people felt they were losing out on the right to mine these gems for themselves, Mr. Raman said that more than 90% of the unlicensed miners were not local, and in fact many were not even from Mozambique. This was confirmed by our discussions with unlicensed miners who came from all over Mozambique. Many of the traders financing their activities, whom we met in Namahumbire or at the mining and washing sites, were from neighboring Tanzania or West Africa (Guinea, Senegal, Mali, or Nigeria). These African traders usually work for merchants in Montepuez who are based out of Thailand, Sri Lanka, or India.

Montepuez and Foreign Buyers

We also visited the town of Montepuez and the area where foreign buyers had set up shop and were buying ruby rough. There were about 500 to 600 Thai buyers and 100 to 150 Sri Lankans. The situation there was quite tense. The different buying offices were typically surrounded by metal grids, and armed guards were visible. Some of these buyers were the ones financing the unlicensed ruby mining on the MRM concession.

Community Relations and Corporate Affairs

About 90% of MRM’s employees are local inhabitants. The company supports the workforce not only through salary and benefits but also by helping them develop skill sets that can be used after the deposit is depleted. The company employs around 600 people and is reportedly one of the largest taxpayers in Mozambique.The company’s hiring of local residents to work in the bulk sampling project is part of MRM’s commitment to the community and one of the needs expressed to Mwiriti by the community leaders. MRM is the first employer some of them had ever worked for. They had never been exposed to the skills needed to work for a mining corporation, but MRM made the commitment to train them to be productive employees.

Auctions

One of the benefits of the Gemfields auction system is that it creates a precise and trusted evaluation system for paying taxes. Mozambique’s government originally wanted to tax the rough rubies before they left the country. Gemfields was able to convince them, with input from Mwiriti, that it was not feasible to accurately value the rubies until they had been auctioned. After the auction the true market value would be realized and a proper tax could be assessed. The government agreed, and the taxes were levied based on the results of the auction in Singapore.

Summary

Only occasionally do gemologists have the opportunity to be part of or to document events that can change the direction of the industry. This is true for both laboratory and field gemologists. Laboratory gemologists may discover a new synthetic or treatment on the market and how to identify it. They may also be the first ones to document the properties of stones from a new source. Field gemologists may visit new sources, see new production from existing sources, observe new manufacturing processes and centers, and see how trading and consuming markets shift. This expedition to the Montepuez ruby mine and the visit earlier this year to the inaugural auction in Singapore enabled the authors to document events that can change the ruby industry and even the colored gemstone industry.Dr. Tao Hsu is technical editor of Gems & Gemology. Andrew Lucas is manager of field gemology for content strategy at GIA in Carlsbad, and Vincent Pardieu is senior manager of field gemology at GIA in Bangkok.

DISCLAIMER

GIA staff often visit mines, manufacturers, retailers and others in the gem and jewelry industry for research purposes and to gain insight into the marketplace. GIA appreciates the access and information provided during these visits. These visits and any resulting articles or publications should not be taken or used as an endorsement.

The authors gratefully acknowledge the assistance provided by Gemfields and MRM personnel, including Ian Harebottle, CEO; Adrian Banks, product director; Ashim Roy, head of geology and exploration; Raime Raimundo Pachinupa, executive director; Sanjay Kumar, project manager; Philippe Ressigeac, assistant product manager; Mohun Raman, head of security; and Angus Barthram, logistics manager.