An Overview of the 2014 GIA Brazil Expedition

February 13, 2015

After a brief stop in the historic colonial city of “black gold”—Ouro Preto—we traveled to two of Brazil’s northern states—Rio Grande do Norte and Paraíba—to visit the world’s original source of copper-bearing tourmaline and meet the gem’s discoverer: the legendary Heitor Dimas Barbosa.

Trip Context and Objectives

Brazil is a huge and culturally diverse nation with a wealth of gem and mineral resources. Along with India and China, this South American powerhouse is often described as a “nation of the future” (Rohter 2012). Now the world’s fourth largest democracy and sixth largest economy, Brazil is clearly a country on the rise.Brazil’s beryl, tourmaline, topaz, chrysoberyl, quartz, and diamond deposits are relatively well known to the gemological community. Drawn in by this nation’s diverse and prolific gem production, GIA gemologists visited many of the country’s active mining areas in 2003, 2004, 2009, 2011, and 2012. Our most recent visit, and the subject of this series of articles, took place in April 2014. This trip took us across three Brazilian states—Minas Gerais, Rio Grande do Norte, and Paraíba—to some of the world’s most productive emerald and tourmaline mines.

The GIA team consisted of Andy Lucas, Pedro Padua, and Duncan Pay—all from GIA Education—and Shane Mcclure, representing the GIA Laboratory. The purpose of our expedition was to document the methods used to develop the mines and provide top-quality gem material to a market hungry for colored gems. The knowledge we gained will flow directly into GIA website articles and publications, including updates of education courses. Shane’s goal was to collect samples of emerald and Paraíba tourmaline for the GIA Lab’s reference collection.

Brazil

Paraíba—to some of the world’s most productive emerald and tourmaline mines. Peter

Johnston/GIA.

Emerald Mines of Minas Gerais

The first leg of our trip took us to three emerald mines in Minas Gerais. Two of them—Belmont and Canaan—are among the most modern colored gem mines in the world, with state-of-the-art processing plants and considerable investment in mining machinery and underground workings. They’re both backed by comprehensive geological surveys, core drilling, and computer modeling of ore reserves. The third, the Montebello, is smaller and less mechanized, but its miners share the same resourcefulness and passion for mining.First Leg: Minas Gerais

Our team was only mildly interested in iron ore mining. It was the lure of emerald that brought us here. Brazil’s emerald deposits arise from the interaction of rocks rich in beryllium, typically granitic pegmatites, with rocks rich in chromium and other metals, usually a sequence of volcanic and sedimentary rocks that have been altered—metamorphosed—by heat and pressure (Giuliani et al. 1990). This was the case at the first mine we documented, the Belmont, located just outside Itabira.

Belmont Mine

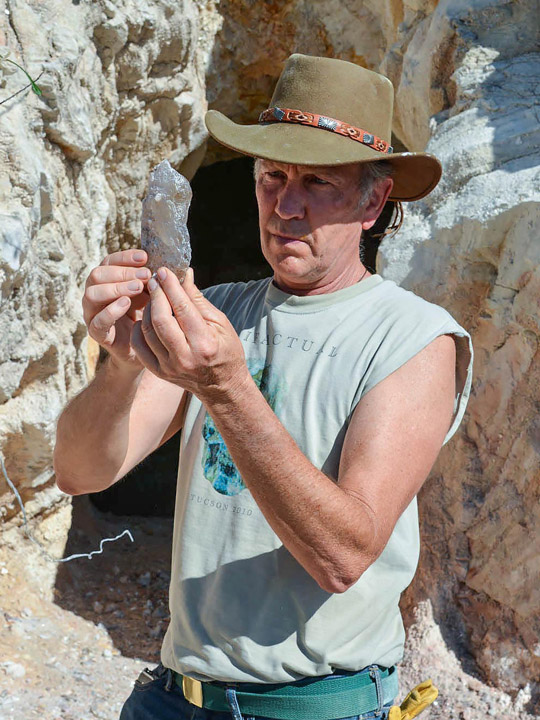

Standing above the Belmont mine’s open pit, we took in the scale of the operation. This was by far the most sophisticated mine we visited. In fact, the Belmont mine can serve as a case study of colored-stone mining, including how to survey, delineate, operate, efficiently process production, and then restore the land to its former, pristine state.

Belmont’s first emeralds were discovered in 1978 (Hanni et al. 1987). At the time, the mine was primarily a cattle ranch. Marcelo’s grandfather initiated mechanized mining in 1982, using a drag-line machine Marcelo described as “rustic.” By 1985, he had purchased a more advanced hydraulic shovel. At that time, mining was still uncomplicated, but by 1994, it had become tougher to work the open pit, requiring the removal of increasing amounts of waste material.

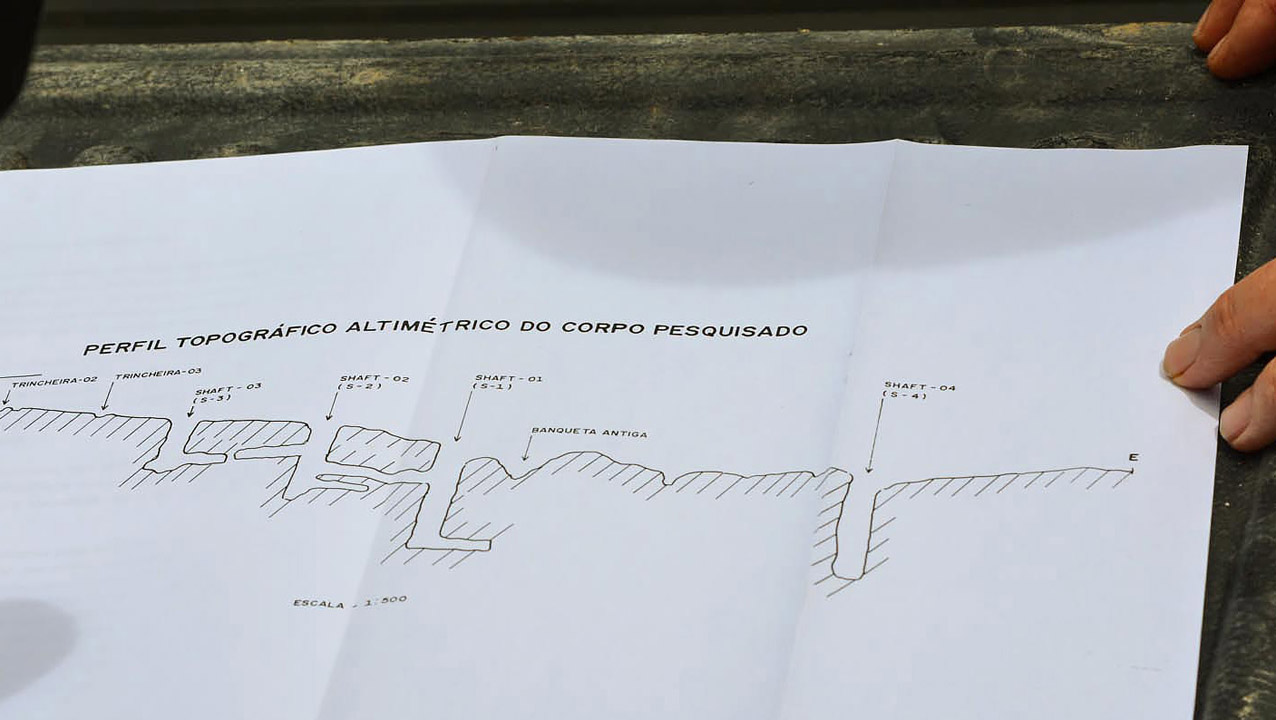

In 1997, to establish the mine’s economic viability, operators initiated a geological survey program supported by core drilling. Because soil and weathered rock were mixed in the open pit, it was difficult to understand the mineralogy of the underlying emerald-bearing rocks, so the mine’s geologist persuaded Marcelo’s grandfather to sink a small shaft 35 meters (115 feet) into the solid rock beneath. This allowed the geologist to determine the “rate” or grade of emerald in the unweathered rock. These tests confirmed that the open pit had a longer life than originally anticipated.

The next step was to install pumps to reduce the water level in the pit, allowing the miners to dig down farther and reach the emerald-bearing phlogopite schist that the geological sampling indicated was below. Marcelo said that the open pit’s size has greatly increased since he joined the mine in 2001. The excavations have now reached chambers at the bottom of some of the original exploratory shafts.

To Marcelo, the data from core drilling is extremely valuable—it’s the mine’s “family treasure.” To date, he explained, over 15 km (9.3 miles) of 3.8 cm (1.5 inch) diameter cores have been drilled. At up to $200 per meter, this is a very significant investment. The core samples do much more than just define the extent and depth of the emerald ore body. They’re very important for mine planning, and aid geological modeling by sampling the underlying rocks. By showing the relative strengths and weaknesses of different rock layers, the cores can also help miners plan the mine’s mechanical structure by showing which layers are capable of supporting underground tunnels.

The sum total of all this analysis, Marcelo explained, is a block model—a three-dimensional computer-generated map—of the mine’s emerald reserves based on chemistry and mathematical modeling of potential emerald grade and quality. This model is continually modified by real emerald recovery and quality rates, taken from actual mining activities. This continually refined model is the basis of all mine planning at Belmont. It provides an accurate prediction of the mine’s remaining reserves and allows the operators to estimate the expense of extracting them. As Marcelo sagely said: “mining without planning is like hunting for gems in the dark.”

Although the current open pit is within two years of the end of its life, Marcelo emphasized that open pit mining at Belmont is far from over. Geological surveys have indicated that a 300 meter (984 foot) thick schist layer—with emerald potential—underlies much of the property, including the processing plant. Although no mining is possible south of the property, where the railroad forms a boundary, open-pit mining can take place north of the current pit. The tailings from future mining will be used to fill the existing open pit.

For every 11 tonnes mined from the existing open pit, only one tonne is ore. The rest is overburden or waste. From that tonne of ore, Marcelo recovers about two grams (0.07 oz.) of rough emerald. On average, those two grams of rough yield two carats of faceted emeralds. By contrast, the underground workings deliver a ratio of one tonne of ore to one tonne of waste.

Marcelo plans to establish a new open pit to the north of the current one, in addition to a smaller one already under development. So there will be three: #1—the “old” one, currently nearly worked out; #2—a smaller one awaiting extension; and #3—a new one not far from the nearby Canaan mine, which we also visited on our tour. The last one (#3) is awaiting an environmental permit so they can remove the trees for mining. Marcelo reckons that these three open pits promise productivity for the next 10 to 15 years.

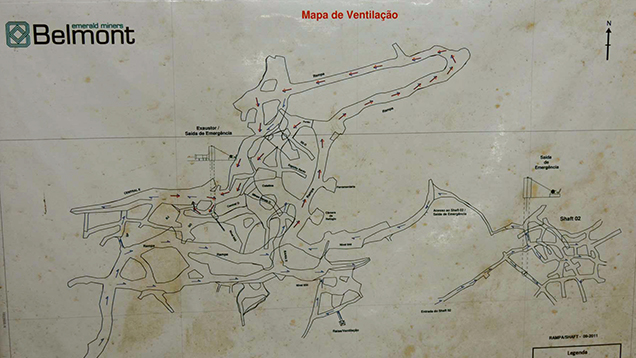

Once Marcelo explained his mine’s open-pit operation, we drove underground inside the cab of a large ore truck, entering through a portal in the mountainside. We plunged down the ramp, entering a network of hard-rock tunnels large enough for our heavy duty truck to navigate.

Those early exploratory shafts provided a tremendous amount of information to help in the creation of a systematic underground mining plan. They let miners directly sample the phlogopite schist to discover how many emeralds it produced compared with the wetter rocks in the open pit. All this was necessary, Marcelo said, because the investment involved in driving a ramp deep into the mountain to bring trucks underground was very high, and the mine operators had to be sure the expense was worth the return.

The ramp we were on extended 666 meters (2,185 feet) into the heart of the mountain and allowed removal of a potential 30 to 40 truckloads of ore per day. At the time, they were only taking 10 to 15 truckloads per day (about 200 tonnes) to the recovery plant.

According to Marcelo, Belmont has used optical sorters since 2004. Unlike human sorters, he says, these machines don’t get tired. The older machine was recently upgraded with new cameras and software and can handle emerald recovery from the fine concentrate. The newer machine has stronger air jets and can handle the medium to coarse concentrate. Each machine has a better than 95% emerald recovery rate.

Belmont maintains a sorting facility in nearby Itabira, which we were able to visit a number of times. At this facility, sorters grade the mine’s production into around 75 quality and size categories. Although the company exports most of its rough emerald for commercial use, Belmont has a small cutting shop with a highly skilled staff, including a master cutter.

a 19.69-ct. beauty. This fine emerald-cut gem would make a stunning centerpiece for a

fabulous jewelry piece. Duncan Pay/GIA, courtesy Belmont.

Canaan Mine

Formerly known as the Rocha mine, the Canaan mine operation dates back to 2005, when it began life as an open pit. The mine closed when the pit was depleted, but it has now reopened as an underground mine. It’s being operated as a joint venture between Belmont and the previous owners, Canaã Mineração Ltda. The mine is just a short drive away from Belmont, along a dirt track.Production began in 2012, and the ramp has just reached the main phlogopite schist ore body, which the operators have been mining for 3 to 4 months. Because of its reserves, Marcelo expects the Canaan mine to become a major producer of good-quality emerald.

In Marcelo’s opinion, the two mines are complementary: Canaan produces some bigger crystals, but they’re typically lighter than Belmont’s smaller, more strongly colored material. Even so, there’s considerable overlap between the two mines, so it can be hard to distinguish each mine’s production.

Chemical analysis of Canaan’s phlogopite schist source rocks reveals they contain less chromium than Belmont’s. On average, Canaan’s emeralds are lighter in color, but crystallization seems to have occurred at lower temperatures, allowing growth of larger crystals than at Belmont. Marcelo envisions two separate emerald mineralization events: first at Belmont, then a second one that produced just a few more stones at Belmont along with significant quantities at Canaan, although they incorporated less chromium. He theorizes that at least two tectonic events were behind the emerald mineralization in Belmont and Canaan, and that a possible third one created the nearby Piteiras and Nova Era deposits.

Montebello Mine

At the time of our visit, bright sunshine alternated with sudden cloudbursts. Before leaving Belmont, Marcelo advised us that the rainstorms might make many of Nova Era’s independent mining operations hazardous. “Sergio’s mine is safe—I recommend you just go there,” he told us.Sergio Martins’ operation—the Montebello mine—is situated amid lush vegetation, just a little bit above the independent miners’ village of Capoeirana, and about 6 km (4 miles) from Nova Era.

Emeralds were first discovered near here in quantity in 1988 (Epstein 1989). The exploration that led to a mining boom in nearby Capoeirana was, in fact, triggered by the discovery at Belmont. Production has dwindled here, due to the lingering effects of the recent economic recession and the deeper levels—often more than 100 meters—required to reach areas of emerald mineralization (Lucas 2012).

Sergio explained that they were following a promising new vein that dipped steeply farther underground, so they had to sink a new vertical shaft to follow it down. Neighbors in an adjacent mine have already found a productive vein at about that level. When Sergio and his miners sunk their shaft, they located a 7-meter (23-foot) thick seam of soft black schist underlain by granite.

According to Sergio, the vein is “nice dark schist” with folded stringers of quartz. Emeralds occur in the boundary where the quartz meets the schist, but they’re hard to spot; he explained that “they like to hide.” The dark color of the schist and the presence of quartz are good indications that emeralds are nearby, as are pale beryl crystals. Sergio and his miners plan to work on this vein for the next few months. From this new 40-meter-deep shaft, they’ll drive a new horizontal tunnel out into the schist. Sergio is not sure if there are many veins, or if it’s just one that’s folded back upon itself many times, so they might be sampling the same layer at many different levels.

Montebello’s new vertical shaft to where the miners have exposed a layer of potentially

emerald-bearing schist. Duncan Pay/GIA, courtesy Montebello mine.

Sergio told us the emerald mineralization in the surrounding area appears to start in Nova Era and finish at the Belmont mine. Between them is another—currently unworked—mine, called Piteiras, which he used to operate. Mining stopped there due to ownership disputes that, Sergio said, might be resolved shortly.

Sergio explained that each area seems to have certain characteristics. At Nova Era, there are more crystals with better luster, and they tend to be bigger. At Belmont, the stones are a little bit smaller, but have stronger color. Emeralds in Piteiras—the deposit located between the other two—appear to have a winning blend of both characteristics: fine luster and good color.

To show us an example of the Montebello mine’s output, Sergio and his mine manager opened a sealed bag. He spread out a pile of glittering black schist that gleamed with bands of white quartz. At first the collection looked unpromising, but the chrome green of emerald quickly became visible, often at the junction between the white quartz veins and the dark schist.

Ouro Preto

After our visit to the Montebello mine, there was just enough time on a Sunday afternoon for a brief trip to the historic colonial city of Ouro Preto. “Ouro preto” is Portuguese for “black gold.” The city was founded in 1711 following the discovery of this lusted-after metal. Designated a world heritage site by UNESCO in 1980, Ouro Preto has an array of stunning baroque churches, many of them with gold-decorated altarpieces.

churches. Duncan Pay/GIA.

The rebellion was crushed in its earliest stages and Tiradentes was brutally executed, his Ouro Preto house demolished, and the grounds salted so nothing could grow there. Today, Ouro Preto’s central square bears his name and there’s a museum—Museu do Inconfidencia—dedicated to the events of 1789.

This brief pause ended our short survey of Minas Gerais’ emerald mines. After returning to Itabira, we left early the next morning for a visit to what might be the most productive tourmaline mine in Brazil, if not the world.

Cruzeiro Tourmaline Mine

To reach the next mine in our itinerary, we drove about 214 km (133 miles) northeast of Itabira. The journey wasn’t that comfortable—our car was weighed down with camera gear and we rode with suitcases on our laps. We stayed overnight at Governador Valadares, a city much bigger than Itabira, with a population of over 260,000.After settling into our city-center hotel, the friendly hotel staff tipped us off to a great churrascaria, just a short cab ride away. A churrascaria is a Brazilian-style restaurant where meat is barbequed “churrasco” style over charcoal or glowing wood. A continual stream of waiters brings a nearly endless supply of barbequed, skewered beef, pork, and chicken. A little rotating colored flag on your table alerts the waiters to stay away (red) or bring more (green). It wasn’t that long before the meat supply overwhelmed and finally defeated us.

The next morning, our hosts met us for the journey to the Cruzeiro mine: Douglas Neves, Beatrice Neves, and her son, Antonio de Neves, Jr. The Neves family owns the mine under the business name of Nevestones.

They were great company, and they described the mine’s history as we made our way out of Governador Valadares and through an increasingly rural landscape of small towns and cattle ranches. Worked for mica during World War II, the mine began producing tourmaline in the 1950s, which is when the Neves family connection was established. Since then, the Cruzeiro mine has been highly productive and has gained fame for its high-quality gems and tourmaline mineral specimens (Procter 1985).

Jose Neves, Douglas’ father, worked the mine with his brother for many years before it was acquired by Julius Sauer of the renowned Amsterdam Sauer gemstone and jewelry company. In 1982, believing that the deposit had huge future potential, Jose Neves bought the mine from Mr. Sauer. He and his brother were almost immediately rewarded with spectacular tourmaline finds. Tragically, an airplane accident in 1992 claimed the lives of Jose, his brother, and other Neves family members.

As we gained altitude, the road became increasingly rugged, culminating in a steep, switchback dirt trail that tested our vehicles. Finally, about six miles from the town of São José da Safira, we arrived at the top of a small mountain. There, we entered the main Cruzeiro mine compound, which appears almost “Shangri La” –like,” with stunning views overlooking the surrounding countryside.

The Cruzeiro mine remains a prolific source of gem tourmalines and mineral specimens. According to Douglas, the mine produces about 8 tonnes of particolored, blue, green, and rubellite varieties annually. About 100 miners work three of the four significant pegmatite veins, the largest of which extends for 1300 meters (0.8 of a mile) and measures up to 60 meters (almost 200 feet) wide.

Douglas explained that, due to the mine’s productivity, security is essential, and the monthly costs of securing the mine site against unauthorized mining run to several tens of thousands of US dollars.

Douglas took us to the scene of a recent find: a fabulous pocket that contained over 2 tonnes of pink tourmaline. Some were kilos in size, and many were of specimen grade. At this level, he explained, they’ve drilled only 20 meters into the pegmatite, so there’s the prospect of encountering more pockets as they go deeper.

Back on the surface—it’s a heart-stopping return journey up those ladders—we observed tourmaline crystals emerging out of recent production at the mine’s washing plant. In a simple concrete tub about 1.5 meters (5 feet) in diameter, a pair of workers used circular washing pans and practiced swirling motions to process the loose, easily crumbled white ore in the water. Soon, dark rods of green and squat prisms of particolored tourmaline emerged in their baskets.

Green and blue tourmaline goes to Nevestones’ cutting office in Governador Valadares, but any crystals with a pink component are sealed into a bag and shipped off to Nevestones’ business partner, Miranda Costa, for processing at the Miranda Group’s factory in Shenzhen, China. Most of the gems produced there are sold in China’s domestic market, where pink tourmaline is in strong demand.

Our visit to the Cruzeiro mine demonstrated the richness of this deposit and its importance to the supply of fine tourmaline to the world’s markets. It’s a mine we intend to watch carefully. And we will definitely return and report on the mine’s progress in the near future.

Paraíba Tourmaline Country

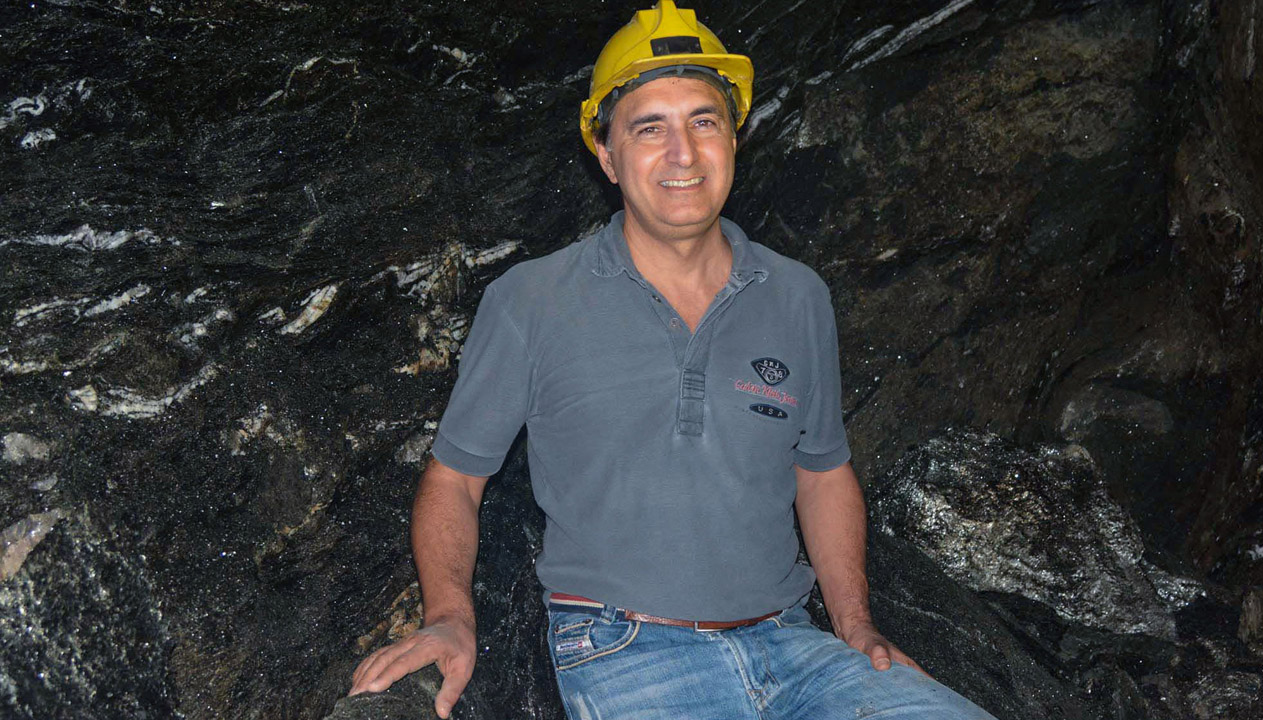

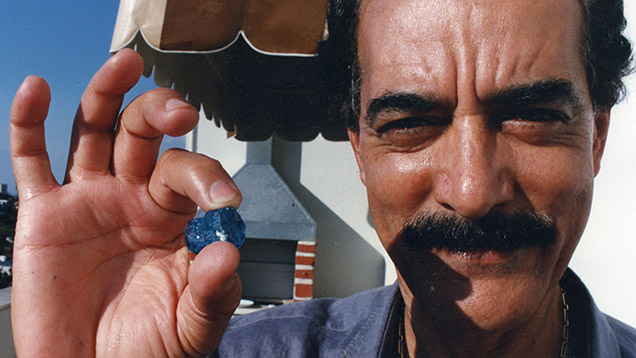

The second leg of our gemological quest took us to the site where, in 1988, vivid copper-bearing tourmaline—since dubbed “Paraíba”—was first plucked from the earth by Heitor Dimas Barbosa. He’s the near-legendary visionary whose belief that something special was hidden within the rocks sustained him through years of fruitless prospecting to final discovery.After a short early morning flight from Governador Valadares to Belo Horizonte, another five-and-half-hour flight took us far up Brazil’s northeastern corner, to the coastal resort of Natal. Natal is Rio Grande do Norte’s state capital and its largest city. It is home to 1.3 million people, and well on its way to becoming Brazil’s top tourist attraction due to the lure of warm seas and miles of sandy beaches.

with Heitor Barbosa, his knowledge of the Paraíba tourmaline story and the local

geology, along with his Portuguese language skills, made him a great addition to the

team. Andy Lucas/GIA

Additionally, small-size rough from mines in Paraíba and Rio Grande do Norte make superb melee-size gems because they retain those vibrant colors in sizes below 2.0 mm.

After a one-night stay at a Natal beachfront hotel, we set off for the interior. Entering Rio Grande do Norte, we noticed striking differences in climate and vegetation as we headed inland from the Natal coast. The interior landscape was parched compared to the verdant country we saw in Minas Gerais.

Second Leg: Rio Grande do Norte and Paraíba

The tough, arid landscape hints at the difficulties local people have making a living in this part of Brazil. Beyond small-scale farming and ranching, only mining and the manufacture of ceramic tile are available to sustain economic activity. Mining has historically centered on industrial minerals like beryl, mica, quartz, feldspar, and kaolin clay (used in the manufacture of paper, rubber, porcelain, and other materials), as well as ores of uranium and tin and rare metals like tantalum, niobium, tungsten, and gold. Gems are often byproducts of this industrial mining. The area is especially rich in pegmatites.

Mineração Terra Branca (MTB) Brazil Paraíba Mine

The first mine we visited in this state—the Mineração Terra Branca (MTB) Brazil Paraíba Mine—is just on the outskirts of Parelhas, a town about a 30 minute drive (30 km, or 19 miles) north of Acari. Parelhas marks the northern edge of a ridge of low, rounded hills that sweep in a curve to the south and west from Rio Grande do Norte, toward the famous tourmaline occurrences at Mina da Batalha in Paraíba state. Unlike the rocks at the Batalha mines, the feldspars in the pegmatites at the MTB mine are largely unaltered. At Batalha, they’ve been mostly kaolinized—altered to white kaolin clay (Shigley 2001).The MTB mine’s low buildings and abundant white tailings mark its location. Mine owner Sebastian Ferreira escorted us into one of the whitewashed buildings and showed us many specimens from the mine. The collection included bright blue rods of tourmaline in quartz, translucent-to-transparent rough, and smaller transparent rough pieces in bright purple, green, and blue hues. Copper bearing tourmaline was first discovered here in 1991 in what became known as the Mulungu mine. MTB has operated the mine since August of 2000 (Shigley 2001).

worker uses a stout cane to push us off from the walls. Duncan Pay/GIA, courtesy MTB

Brazil Paraíba Mines.

MTB also operates a sorting and cutting operation in nearby Parelhas, where melee-size rough is graded into categories by size and quality before being sent overseas for cutting. Larger, often translucent to opaque, material is cabbed into calibrated sizes. Matrix material with interesting patterns is sawn into slices and shaped for setting into interesting one-of-a-kind jewelry pieces.

The Batalha Mines

After observing a copper-bearing tourmaline mine in Rio Grande do Norte, we ventured farther south into Paraíba state to visit the most famous mining area of this type: Mina da Batalha. Today, there are three concerns sharing the Batalha mine site. We visited two of them. The mines are about 4.5 km from the town of Salgadinho, itself an hour-and-half drive from Parelhas (about 78 km, or 48 miles).

Since the early 2000s, production has been limited, with much of the recovered material coming from processing the tailings from previous mining. In spite of this, the two Batalha mines we visited—Ubiratan and Barbosa—were both sinking new shafts to deeper levels in the hope of finding fresh tourmaline mineralization.

Parazul Mineração Mine

The first of the two mines we visited was operated by a miner named Mr. Ubiratan. He operates the claim immediately below and south of Heitor Barbosa’s. We stopped at his house to see some samples brought up from a new lower level about 70 meters (230 feet) below the existing workings. He showed us euhedral quartz crystals containing rods of blue-green tourmaline along with broken pieces of bright blue and mauve tourmaline. They were translucent to opaque, and their colors were very bright and looked like they were probably caused by the presence of copper and manganese. Many occurred along with purple lepidolite, which the mine’s operators consider a promising association.

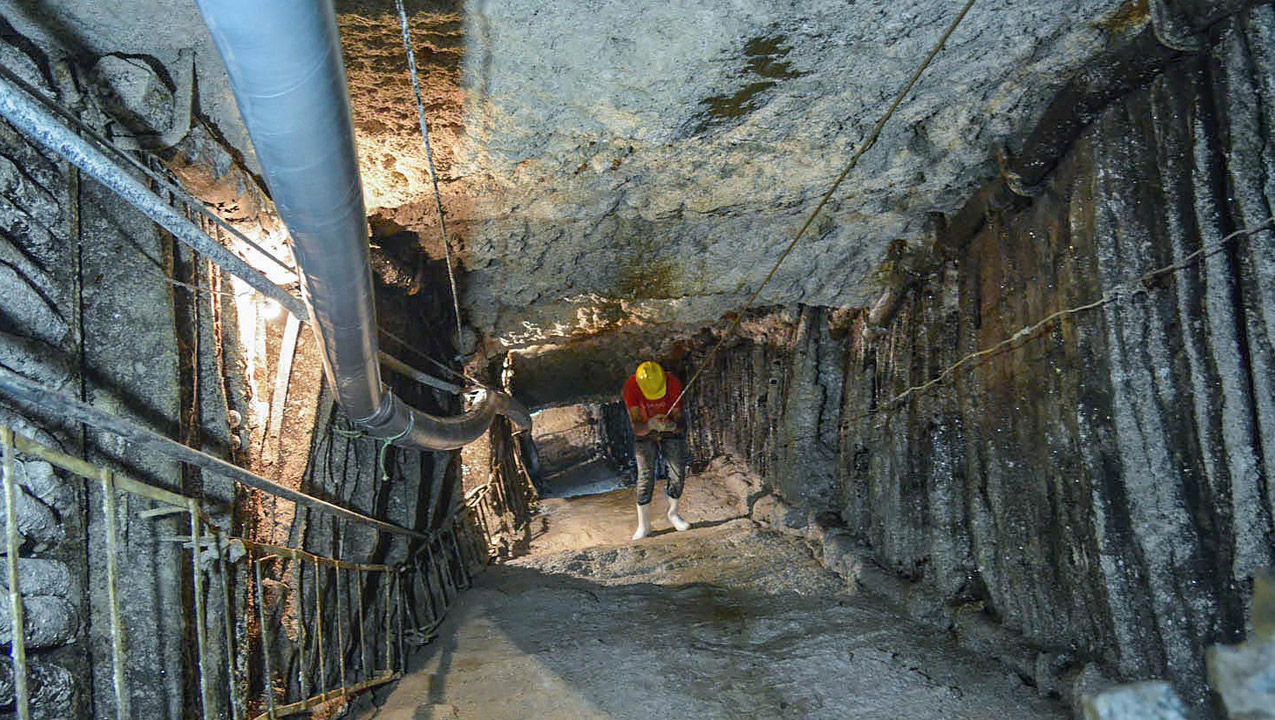

To access Ubiratan’s mine we rode underground in a cage elevator very similar to the one at Montebello. After descending about 50 meters (164 feet), we arrived at the bottom of the shaft. This was quite unlike the MTB mine, with its expansive hard-rock galleries. Here, the tunnels are much narrower and the wall rocks are often the extensively kaolinized feldspars of the pegmatite.

Since we were in a much more confined environment, it was impossible not to notice that the white pegmatite wall rocks were so loose that you could make a hole with your fingertips. Because trees are scarce, shoring material for tunnels is in short supply, and some of the small galleries we walked through lacked supporting timbers.

A short distance into the tunnel, we reached the second shaft. A blower blasted air from above through a plastic ventilation duct and down to the workers 70 meters (230 feet) below. It was humid and well above 100oF, so our shirts were soon sticking to our backs. Access to the lower level is via electric winch and harness. Peering over the guard rail, we saw that the shaft descended nearly vertically to join a horizontal tunnel or gallery far below. Brian Cook was the first to gingerly step into the harness for the journey down.

Next, he was swung out on a small gantry over the precipice and the electric winch whirled into life, slowly playing out the cable. This let him walk down the steeply inclined quartzite wall rock. One slip and he would have swung like a pendulum. Holding the cable with both hands, he carefully negotiated his way down.

Duncan Pay/GIA

Later, Lucas explained that a 20 meter long tunnel led from the bottom of the shaft through kaolinized pegmatite to a small chamber where a miner was at work with a pneumatic drill. It was the part of the mine where the samples we had seen earlier came from. The samples seemed to suggest that the mineralization responsible for copper-bearing tourmaline was nearby.

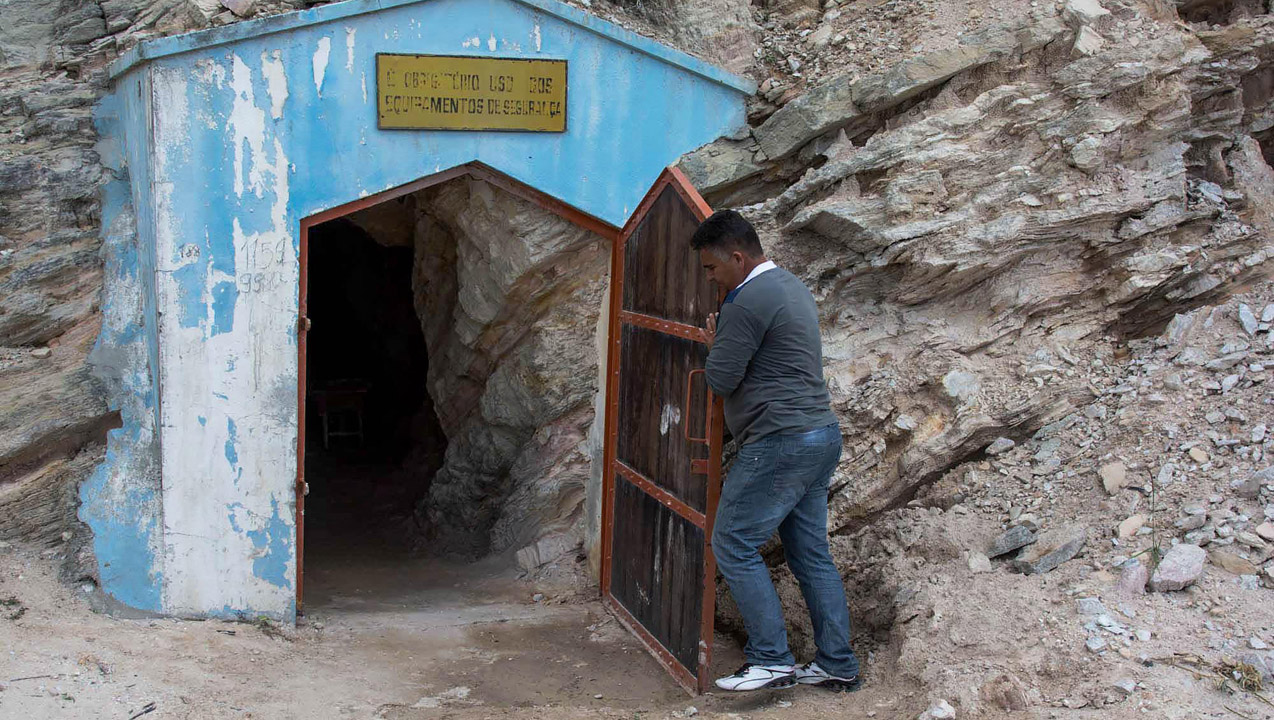

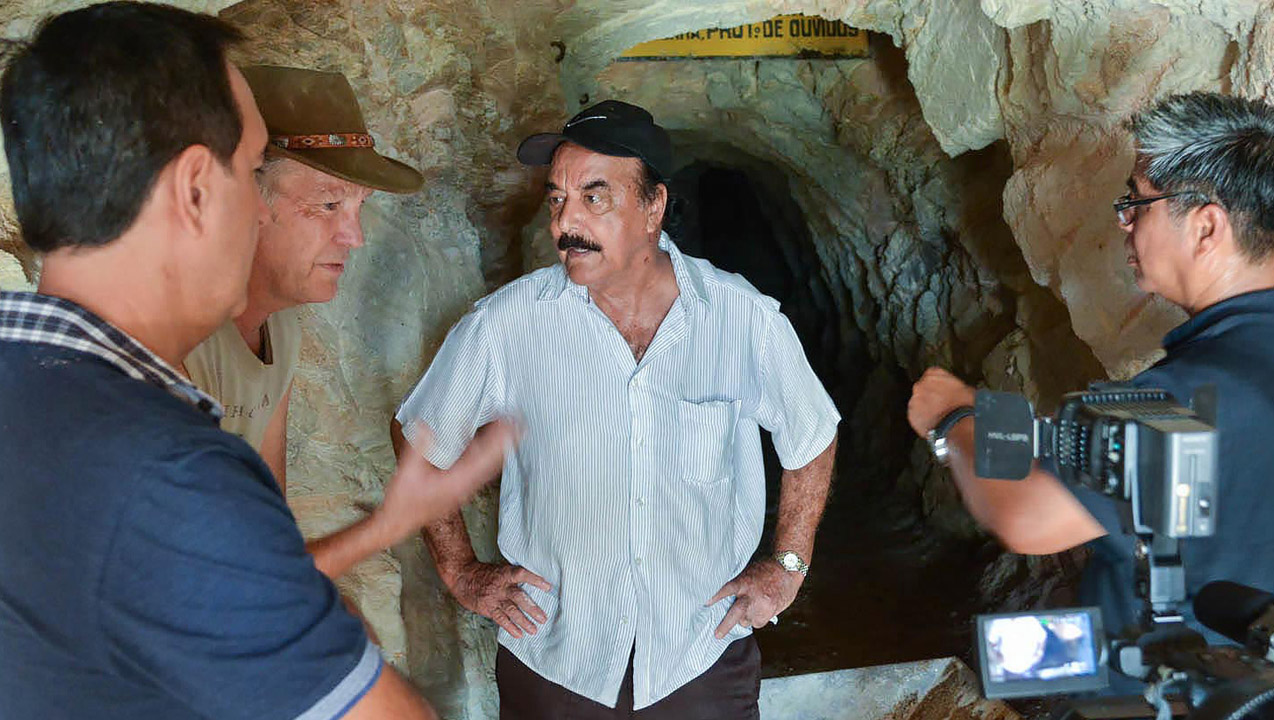

Barbosa Mine

The day after our Parazul Mineração mine visit, we returned to see Heitor Barbosa. Brian telephoned ahead and there was an anxious few-minute wait in front of the Barbosa mine compound gates. Finally an employee emerged to open the gates and we drove inside, where we received a warm welcome from Heitor Barbosa and his son Sergio.The history of Heitor Barbosa’s odyssey of discovery is part of Paraíba lore today. Although we had read about it in many articles (Koivula & Kammerling 1990, Shigley 2001, Wilson 2002), it was a remarkable thrill to meet and talk to the gem’s discoverer in person. Now in his eighties, Barbosa is still vigorous and passionate about his rare blue tourmaline.

Our real purpose for visiting Heitor was to document his discovery of the electric blue tourmaline he’s so closely associated with. As there were no other on-camera interviews that we were aware of, this was a real first. Even better, we conducted the interview in one of the original Mina de Batalha tunnels. From Heitor, we got the story of the mine’s discovery, the excitement of the first production of electric blue tourmaline, and the turmoil of disputed ownership following that. It’s clear his passion still burns bright. From Heitor’s son Sergio, we heard about the mine’s future potential and the work he’s conducting to reach pegmatites at deeper levels than his father’s so-far unmatched production.

After the interview, we toured the mine property, observing the new shaft and the family’s kaolin processing plant. The Barbosa mine also produces high-purity kaolin, which provides supplementary income. As we took our leave, we arranged to return as soon as possible.

Pedra Bonita (Alto Mirador) Spessartine Mine

The final gem deposit we visited is no longer active, but holds promise for the future. This is the Pedra Bonita spessartine garnet mine, also known as the Alto Mirador mine in the gemological literature. Brian had a contact, a local geologist, whose father—José Aderaldo de Medeiros Ferreira—also had an interest in the mine and documented it pretty thoroughly. It was a relatively short drive from our hotel in Acari, past a number of smoking ceramic works, and through a small hamlet, where we met our geologist contact before heading off-road up into the hills.

The deposit clearly has potential, and it could be readily brought back into production if the economic conditions—and demand for the bright orange gem—warrant it.

Conclusion

All in all, this was a fascinating and productive trip that gave us new information along with many thousands of images and hours of video recordings. We were able to document the workings of many important mines to a depth we’ve not achieved before. Our travels also helped us gain many emerald and tourmaline samples from current mining activities that will support the GIA Lab’s identification services.Everywhere we went, our hosts were generous with their time and allowed unparalleled access to their operations. The media we gathered will enrich our education courses and other future publications, both in our journal—Gems & Gemology—and on our website. Look for detailed future field reports for many of the mines we visited on this 2014 trip on the GIA website at www.gia.edu.

Duncan Pay is editor-in-chief of Gems & Gemology. Andrew Lucas is manager of field gemology, and Pedro Padua is a video producer for gemology content strategy at GIA in Carlsbad. Shane McClure is director of identification at GIA’s Carlsbad laboratory.

DISCLAIMER

GIA staff often visit mines, manufacturers, retailers and others in the gem and jewelry industry for research purposes and to gain insight into the marketplace. GIA appreciates the access and information provided during these visits. These visits and any resulting articles or publications should not be taken or used as an endorsement.

The authors would like to thank all the mine operators and their employees for their generosity of spirit and the time they committed to showing us every detail of their mining operations; nothing was too much trouble, and we were made to feel at home everywhere we visited. We thank in particular, Marcelo Ribeiro of the Belmont mine, Sergio Martins of the Montebello mine, Douglas, Beatrice, and Antonio Neves of the Cruziero mine, and Sebastian Ferreira of the Mineração Terra Branca (MTB) Brazil Paraíba Mine. At the Batalha mine site, we thank Mr. Ubiratan of the Parazul Mineração Mine, and especially Heitor and Sergio Barbosa—original discoverers of Paraíba tourmaline.

Epstein D. S. (1989) The Capoeirana Emerald Deposit near Nova Era, Minas Gerais, Brazil. Gems & Gemology, Vol. 25, No. 3, pp. 150–158.

Hanni H. A., Schwarz D., and Fischer M. (1987) The Emeralds of the Belmont Mine, Minas Gerais, Brazil. Journal of Gemology, Vol. 20, Nos. 7&8, pp. 446–457.

Koivula, J. I., and Kammerling, R. C. (1990) Gem news: The discovery of the Paraíba tourmaline mine. Gems & Gemology, Vol. 26, No. 2, pp. 164–165.

Lucas A. (2012) Brazil’s Emerald Industry. Gems & Gemology, Vol. 48, No. 1, pp. 73–77.

Peretti A. Ed. (2009) Chemical variations in multicolored ‘Paraíba’-type tourmalines from Brazil and Mozambique: implications for origin and authenticity determination. Contributions to Gemology No. 9, GRS Thailand Co., Ltd, Bangkok, Thailand. ISBN 978-3-9523359-9-4

Proctor K. (1985) Gem pegmatites of Minas Gerais, Brazil: the tourmalines of the Governador Valadares district. Gems & Gemology, Vol. 21, No. 2, pp. 86–104.

Shigley J. E., Cook B. C., Laurs B. M., & M. de Oliveira Bernardes (2001) An update on Paraíba Tourmaline from Brazil. Gems & Gemology, Vol. 37, No. 4, pp. 260–276.

Wilson W. E. (2002) Cuprian tourmaline from the Batalha Mine, Paraíba, Brazil. Mineralogical Record, Vol. 33, March-April, pp. 127–137.