Hydrophane Opal Treatment

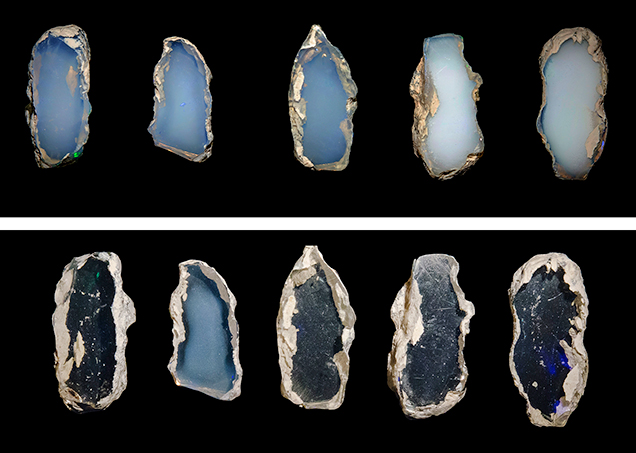

Recently in GIA’s Bangkok lab, an approximately 4 cm piece of rough hydrophane opal was fabricated into five slices for various treatment experiments. Each slice was approximately 0.5 cm thick. Only clean tap water was used in the cutting process, and no other materials besides opal were involved. The opal slices showed a whitish, cloudy appearance in daylight and appeared light brown to brown in calibrated diffused light.

After the cutting step, all five slices underwent specific gravity testing, which gave SG values of approximately 1.93 ±0.03. While immersed in water, the slices displayed obvious weight gain and improved transparency, which indicated that the material was hydrophane opal (figure 1).

The water-absorbing ability of the opal was found to vary through the whole piece, resulting from its non-uniform porosity, and could be calculated as percentage weight changes in water, ranging from 5% to 13%. It took approximately one week to restore the opal’s original weight and appearance.

Two slices were then selected for oil and Opticon treatment experiments. The treatment procedures were identical. The pieces of opal were heated to approximately 80°C and then placed in warm oil or Opticon of the same temperature under vacuum conditions. They were heated continuously for 15 to 20 minutes, which was indicated by the presence of gas bubbles on the opal. Once the slices had fully absorbed the oil or Opticon, there were few, if any, gas bubbles. Afterward, the slices were removed, cleaned with a dry cloth, and left to air-dry overnight at room temperature.

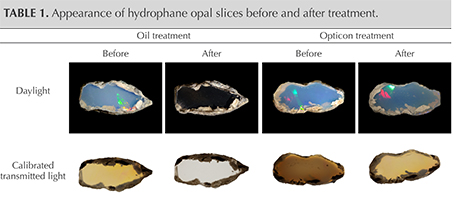

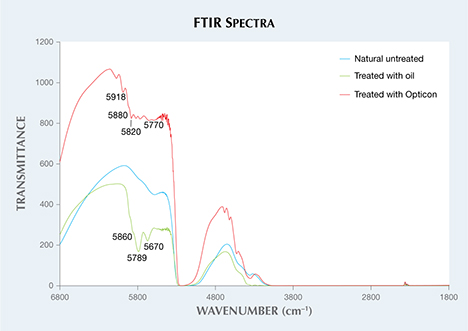

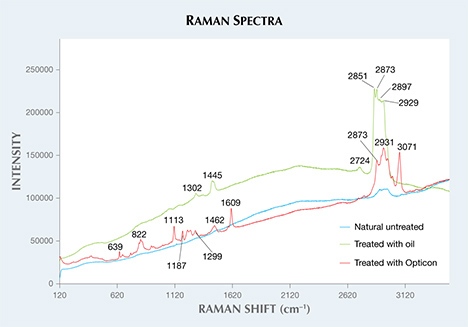

Both treated opal slices were analyzed using a gemological microscope and advanced instruments. Oil treatment improved transparency but destroyed play-of-color (table 1, left). Opticon treatment enhanced transparency while preserving play-of-color (table 1, right). The FTIR spectrum of the oil-treated slice showed oil-related peaks at 5670, 5789, and 5860 cm–1, whereas the FTIR spectrum of the Opticon-treated slice displayed a series of related peaks in the 5600–5900 cm–1 range (figure 2). Raman spectra also demonstrated the presence of treatments. The oil-treated sample displayed peaks at 2929, 2897, 2873, 2851, and 2724 cm–1, while the Opticon-treated slice showed dominant peaks at 3071, 2931, and 2873 cm–1, and a series of smaller peaks in the 600–1600 cm–1 range (figure 3).

While oil and Opticon are not easily observed with the unaided eye or even with a microscope, they are readily detected by advanced instruments. Using Opticon, the process could be combined with other treatments, such as dyeing or sugar-acid treatment, to improve the durability and transparency of opal.

Acknowledgement: The authors thank Jeffery Bergman of Primagem, Bangkok for providing and performing treatment on the Ethiopian hydrophane opal samples examined in this Lab Note.